Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 788

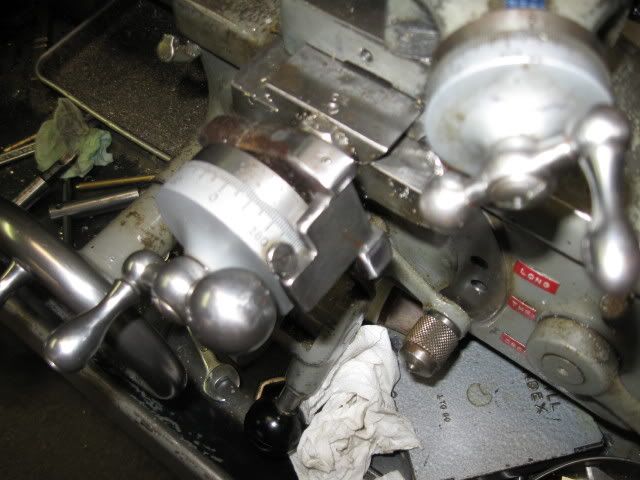

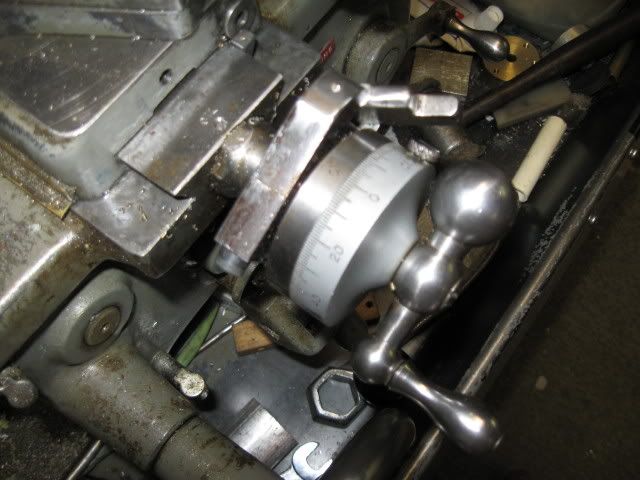

After watching the old threading video I found on the Wells South Bend site I am curious as to how many folk use a threading stop when single point threading. I learned to thread without one. but made one a couple years ago. It seems to speed up threading. Less to think about.

Tin

Tin