rake60

Well-Known Member

- Joined

- Jul 8, 2007

- Messages

- 4,756

- Reaction score

- 124

When it come to cutting a perfectly fitting thread there is no perfect

answer to thread depth. There are just too many variables involved.

ie: tool tip radius, tool spring, cutting finish, ect.

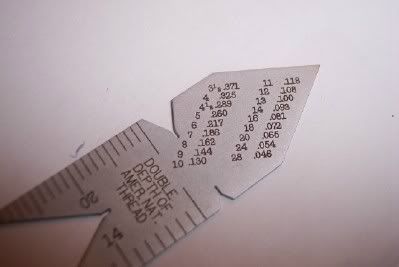

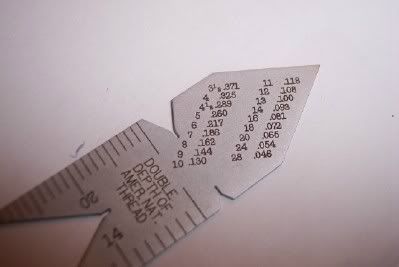

However there are some good guide lines. If you own a thread gauge the

standard "Double Depth" of threads are stamped on the back side of the

gauge.

Divide the number given on the chart by 2 and that is the approximate

depth per side of the thread.

Today I was setting up a job on my machine that called for a 33 X 3.5MM

thread. My cheat sheets don't cover metric threads. Our head programmer

told me to use the .649519 constant to check the CNC's opinion of the

depth. I've only been a machinist for 20 years so naturally this was new

to me.

You determine the actual pitch of the thread. We'll use a 12TPI for an example.

1 / 12 = .8333333333"

.8333333333 X .649519 = .05379"

Convert that to a double depth (.05379 X 2 = .10825")

Huh, same answer as the number .108" given on the thread gauge...

I will admit I'm getting old, but never too old to learn.

Again it is not a perfect solution, but it gives you an idea of where your

headed to. I know there will be people offering the perfect answer

solutions. Those solutions will work 100% of the time on paper. In real life

when the mating part screws on it's right. Until then you take

another cut. If you can throw it on from across the room, call it a practice

piece and try it again. :wink:

Rick

answer to thread depth. There are just too many variables involved.

ie: tool tip radius, tool spring, cutting finish, ect.

However there are some good guide lines. If you own a thread gauge the

standard "Double Depth" of threads are stamped on the back side of the

gauge.

Divide the number given on the chart by 2 and that is the approximate

depth per side of the thread.

Today I was setting up a job on my machine that called for a 33 X 3.5MM

thread. My cheat sheets don't cover metric threads. Our head programmer

told me to use the .649519 constant to check the CNC's opinion of the

depth. I've only been a machinist for 20 years so naturally this was new

to me.

You determine the actual pitch of the thread. We'll use a 12TPI for an example.

1 / 12 = .8333333333"

.8333333333 X .649519 = .05379"

Convert that to a double depth (.05379 X 2 = .10825")

Huh, same answer as the number .108" given on the thread gauge...

I will admit I'm getting old, but never too old to learn.

Again it is not a perfect solution, but it gives you an idea of where your

headed to. I know there will be people offering the perfect answer

solutions. Those solutions will work 100% of the time on paper. In real life

when the mating part screws on it's right. Until then you take

another cut. If you can throw it on from across the room, call it a practice

piece and try it again. :wink:

Rick