The master cam isn't as easy as just machining a radius into a cylinder although for some simple engines it wouldn't be far off, that's just my crappy drawing.

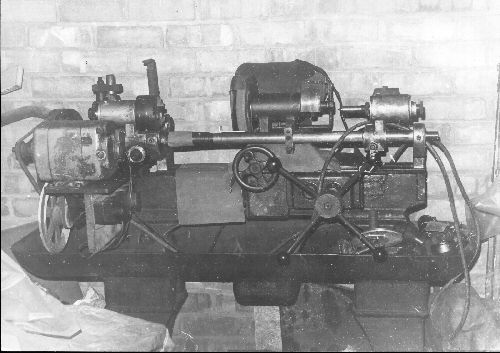

In the days when we were doing this, mid to late 1970's we had no CAD and it was all the hard way.

There were two methods we used, copy and development.

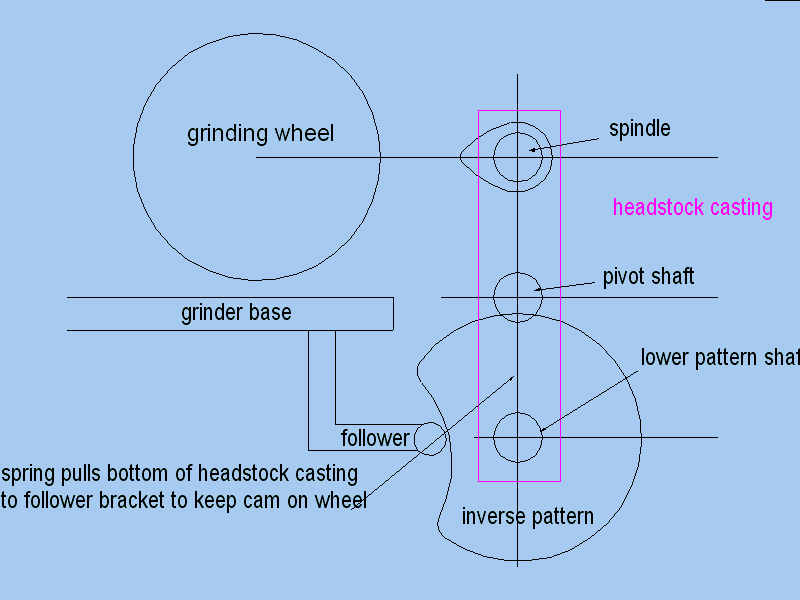

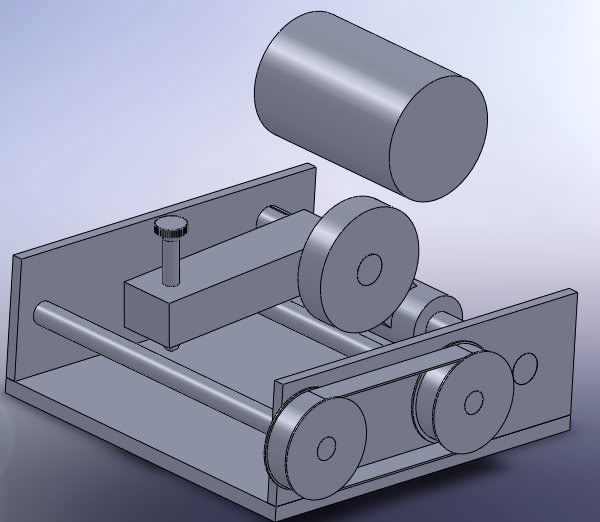

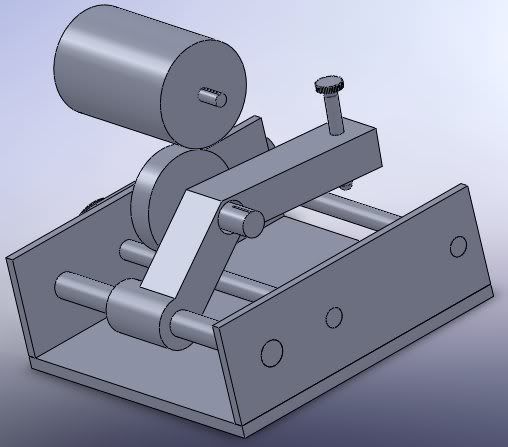

Copy was reasonable easy in that a known good cam was fitted up to the spindle, the master cam [ MC from now on ] was packed in or out and the follower replaced by a scriber.

Keeping the copy cam in contact with the wheel the whole lot was revolved one rev to scribe a mark on the MC which was then removed to be cut and filed into shape, we used alloy plate from 1/8" to 1/4" depending on what was to hand.

In the development method this was used where we had no cam or wanted to try a profile from another cam onto ours.

Many of the cams were welded up with Stellite and then reground to another shape.

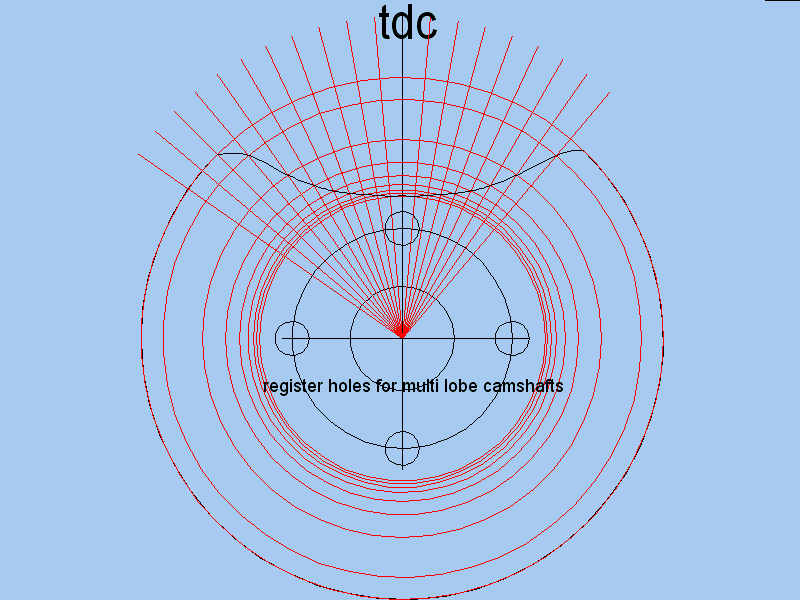

This was done by drawing a set of radial lines every 5 degrees and the opening and closing points marked.

Then diameters were laid off for lift at every 5 degrees and a line blended thru them. pic below:

This was the whole idea of working on larger master cams as it didn't get so cluttered and like a pantograph any errors were reduced by the scale factor.

If you are working on say a 6" wheel and the MC is 6" but you are grinding a 1/2" cam you are working at a 12:1 ratio

so any slight errors get canceled out 12:1

This MC blank has to be laid out as a 6" cam, not a large cam with a small lobe, this way everything stays in scale and the same MC can be used on any size cam provided that the profile is what is needed.

The cutout looks funny with it being the inverse but the data is exactly the same as if you drawn a proper cam and did the same as regards lines every 5 degrees and circles. You can even get the same data with a known cam and a degree plate and dial gauge.

The 4 central holes I missed out of the original drawing and these are so you can move the MC in relation to the camshaft being made so you can do multi cylinder engines.

Today with CAD and even CNC what we did years ago is a damn sight easier. The system does work, the original cam grinder did countless numbers of cams and the racing miles done by these engines must run into the tens of thousands given the average racing bike in the Isle of Man does about 1200 miles in race week including practice.