Richard Horne

Member

- Joined

- Dec 4, 2008

- Messages

- 15

- Reaction score

- 12

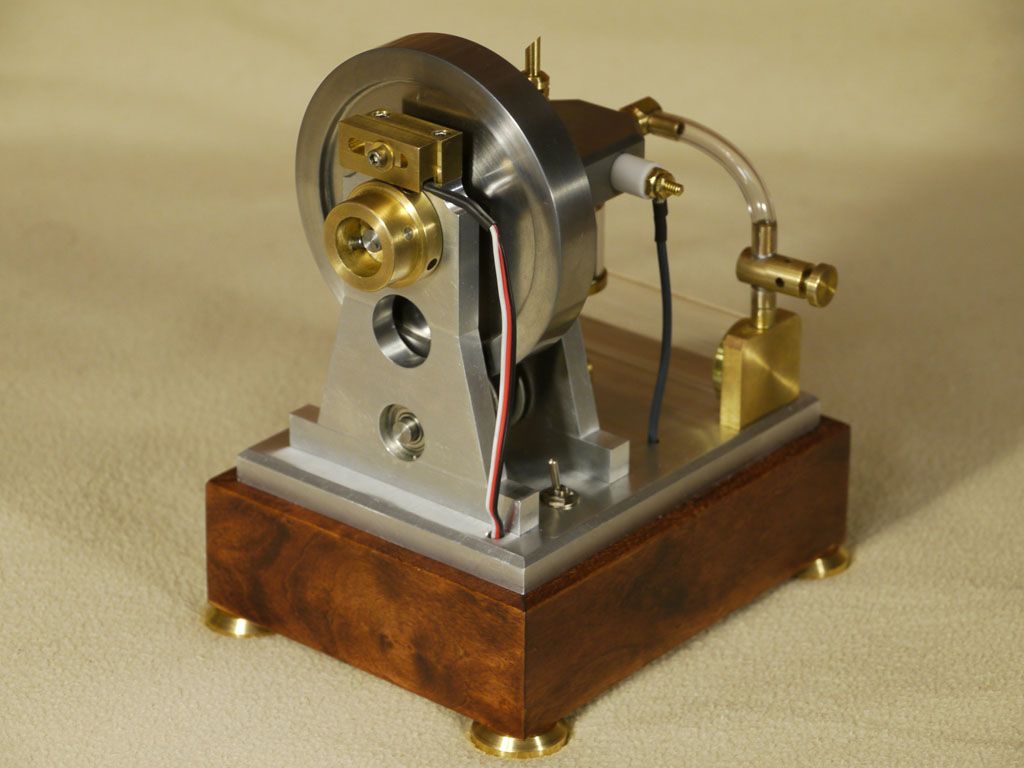

Simple 4 Stroke

This is the simple 4-stroke glass cylinder engine designed by Jan Ridders. I chose this engine mainly because its simplicity nicely matches my experience and shop equipment. It is also a very nice looking engine with the clever use of a glass cylinder that makes combustion visible as a low blue flame. Anyone interested in construction details for this engine should see my posting in the Work in Progress forum.

The engine vacuum pulls fuel vapor from a cylindrical glass reservoir that acts as a rudimentary carburetor. An adjustable valve mixes air with the fuel vapor, which is then introduced into the top of the cylinder via a rotary valve turned by the flywheel. Ignition is via a battery powered Capaciter Discharge Ignition housed in the wooden base.

Below is a short video of this engine in operation.

[ame="https://www.youtube.com/watch?v=_-4zG4dOOAE"]https://www.youtube.com/watch?v=_-4zG4dOOAE[/ame]

Learning how to reliably start this engine has taken some time. The mixing valve adjustment is very tricky, and I found it difficult to find a predictable setting that could be relied upon for starting. The plans suggest initially setting a very lean fuel-air mixture and advancing to a richer setting once the engine begins to run. This procedure is meant to initially burn off a higher concentration of volatile fuel vapor that has accumulated in the reservoir. This does seem to work, but it requires a bit of practice and experiment to be successful.

The plans also suggest using an electric drill with special attachment to turn the engine while advancing to a richer fuel-air mixture. This isnt a good solution unless one is willing to bolt the tiny engine to the workbench. Otherwise, one hand must hold down the engine, one hand must operate the drill, and the third hand must operate the mixing valve. I was never able to accomplish all three of these things simultaneously.

My current technique is to set the mixing valve and then flip the flywheel by hand to start the engine. I have become more proficient at starting as Ive gained experience. The technique of winding a cord around a starting pulley has been used successfully be others, and I may give this a try in the future.

Overall, building and running this engine has been very entertaining and rewarding. It has been my first attempt at an internal combustion engine, and I am very pleased with the completed model.

Last edited: