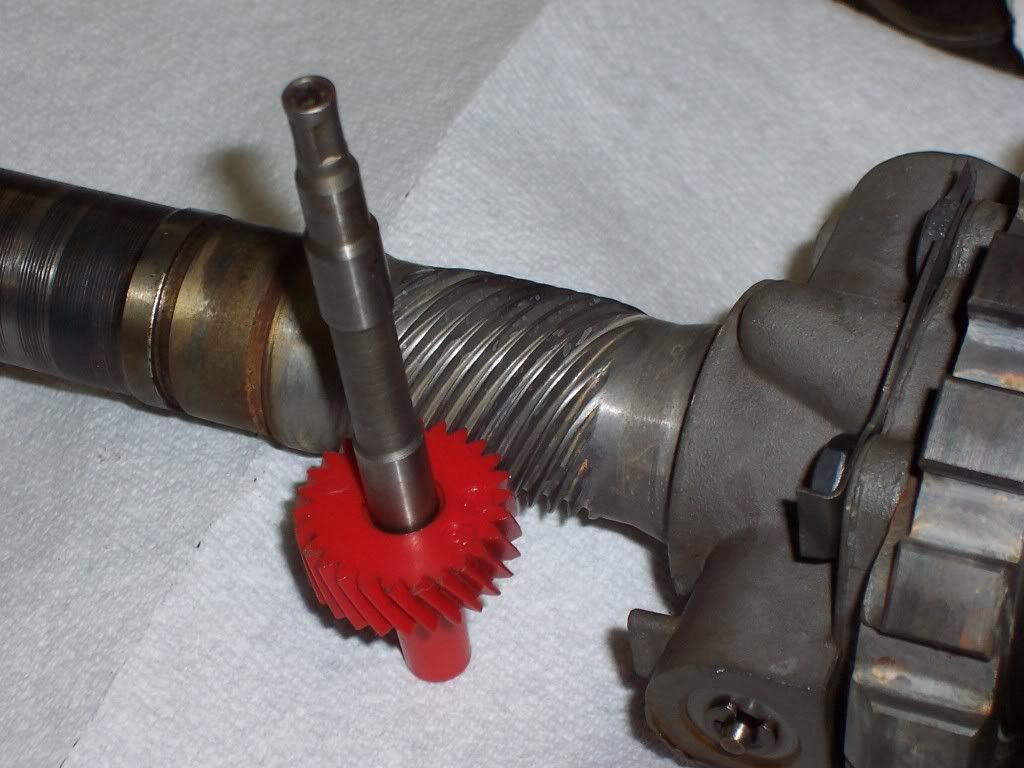

I happen to have an automatic transmission rebuild going on this week. This is for a car I'm putting together this spring to go racing. The output shaft has a helical gear hobbed onto it for the speedometer drive gear to mesh with. I counted the number of teeth on the gear and came up with 13. I used to do more transmission rebuilds 20 years ago than I do now so I have collected spare parts for the trans that I use. I looked in my box and found a 26 tooth speedometer gear. So I was wondering if I could salvage a bad output shaft and chop saw the gear portion away and then clean it up on the lathe. I'm going to see a friend of mine that does alot of transmissions to see if he has any bad shafts laying around and if not, then save me one when he does find one. The shaft is probably made from 1053 steel and is hardened so I don't know how successful I will be. I'll just have to try. The driven gear is plastic so I question if it will be strong enough to drive a model sideshaft. I figured I'd post this to see what you guys think. Will this be a good source of sideshaft gears? Dave