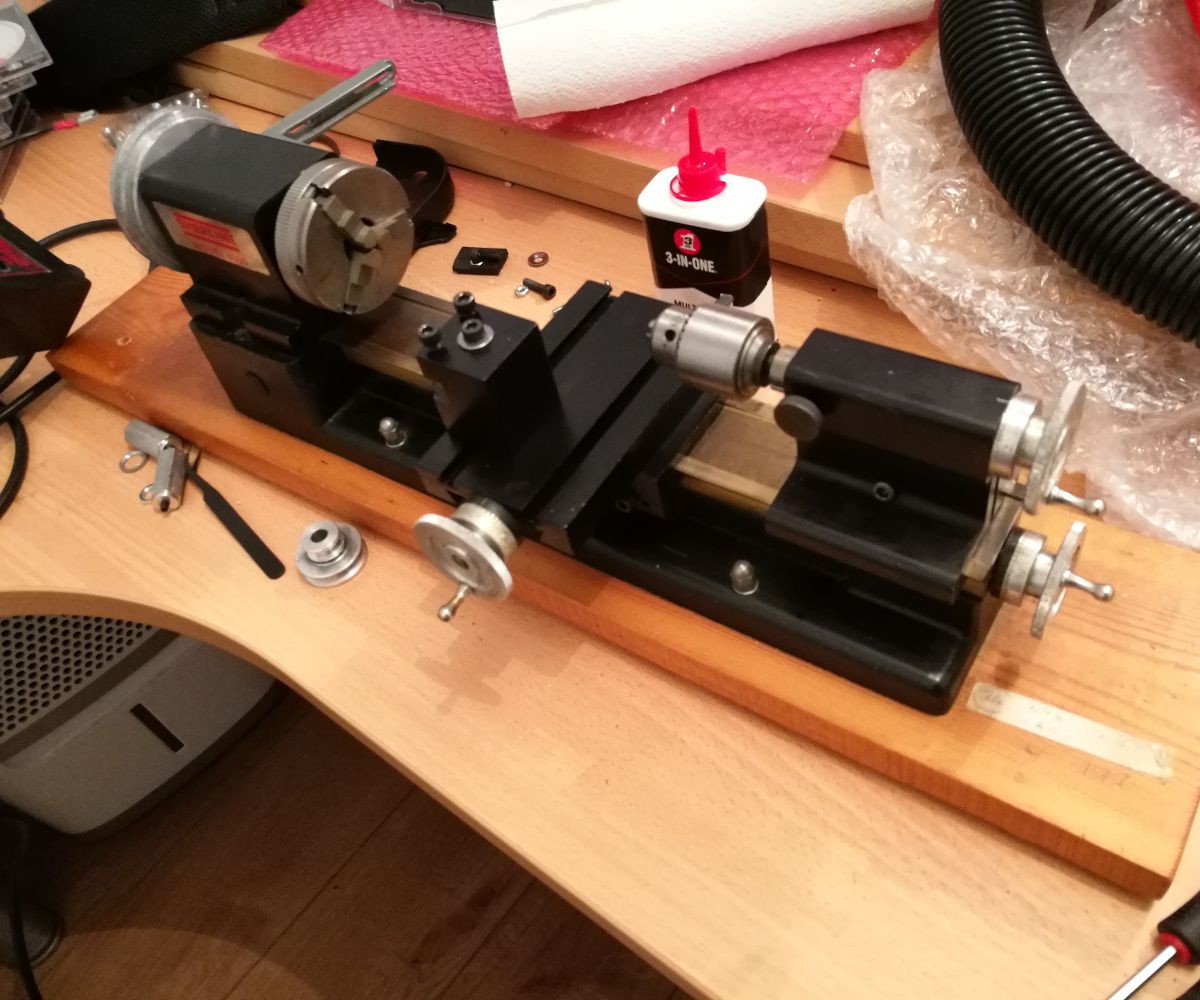

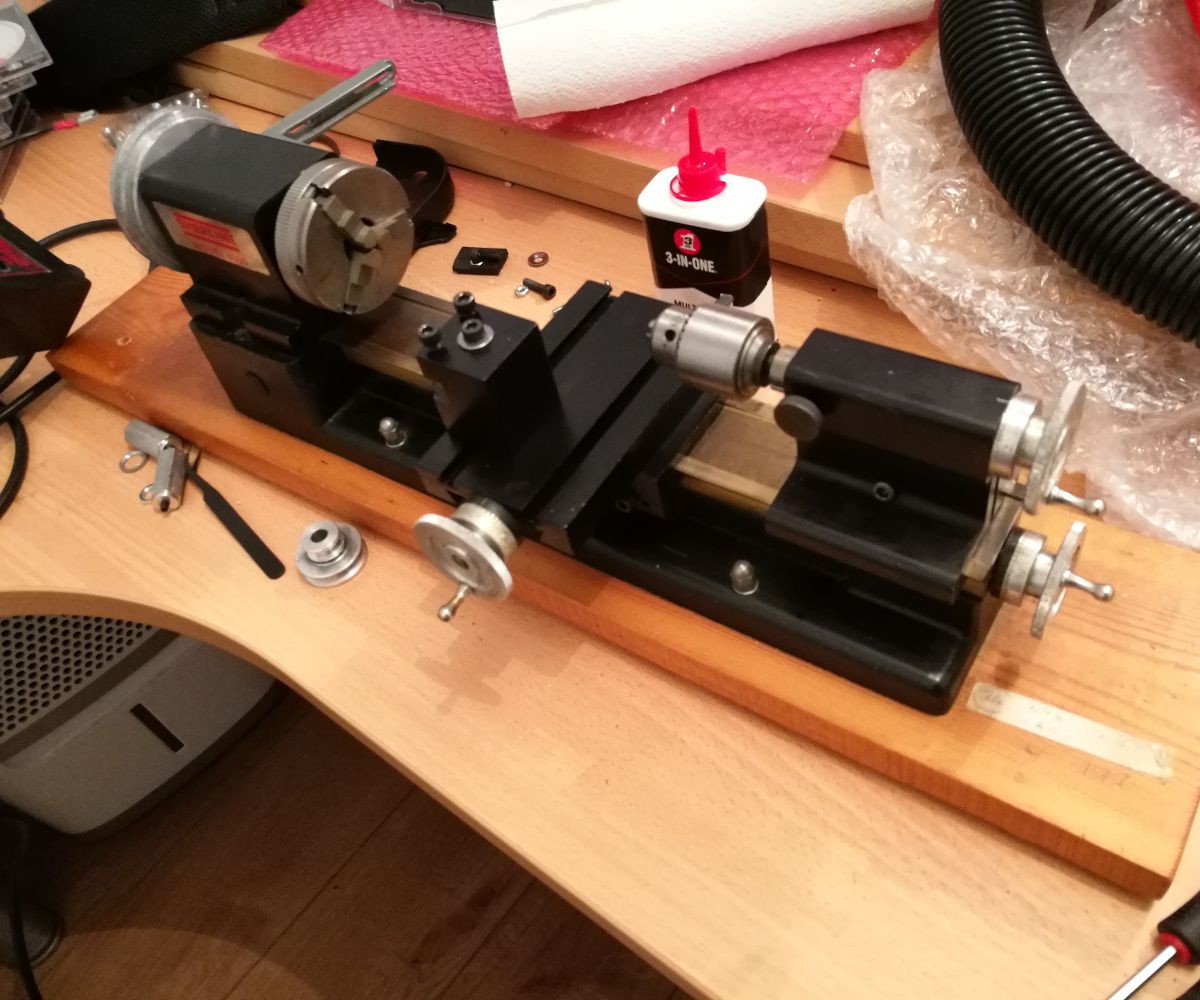

I am just starting out with machining over the last year and I picked up a Sherline mini lathe. The bread and butter of mini lathes I guess!

It's a fair bit older than me, being brass. But it seems well aligned still and I have been having good fun learning with it.

When it arrived, the motor was broken, brushes had burnt down and filled it with black soot. The switch was worn out and corroded inside so it would not turn on. And the control board would short out despite me disconnecting anything, checking the components...

So fixing time!

It was a bit of a pain to find the right components, I guess I could have bought a new speed control assembly from sherline. But this was cheaper and the same result. I hunted for a while for some material online about swapping the electronics on an old sherline. No luck, so maybe this post helps to guide someone else at one point!

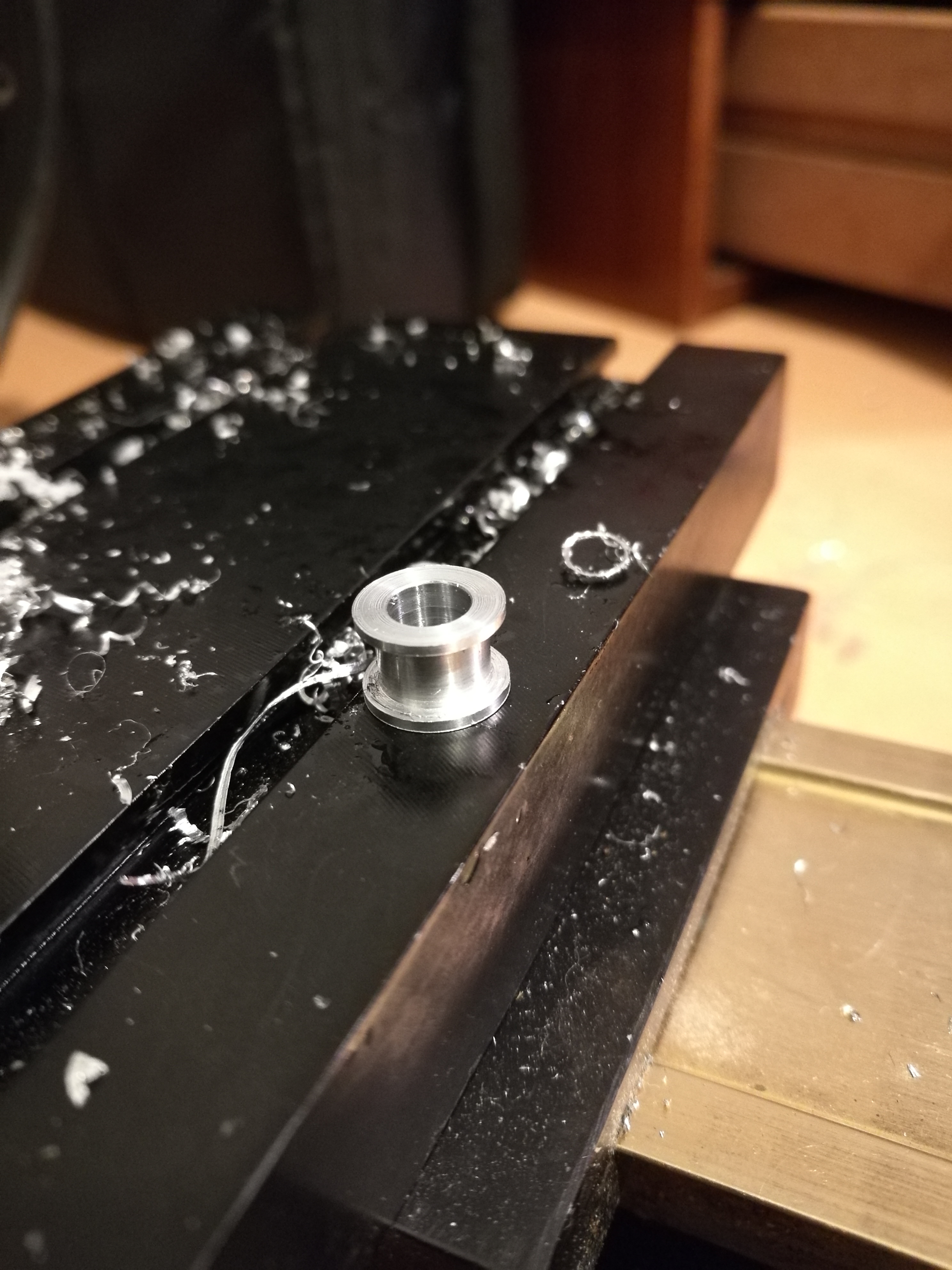

First I had to disassemble the problem end, here is what is left after removing the electronics and motor.

I opened up the motor and cleaned it out, reseated the brushes. The bearing could do with replacing as it clicks per rotation. I'll fix that if it gets too bad. Didnt photo this step

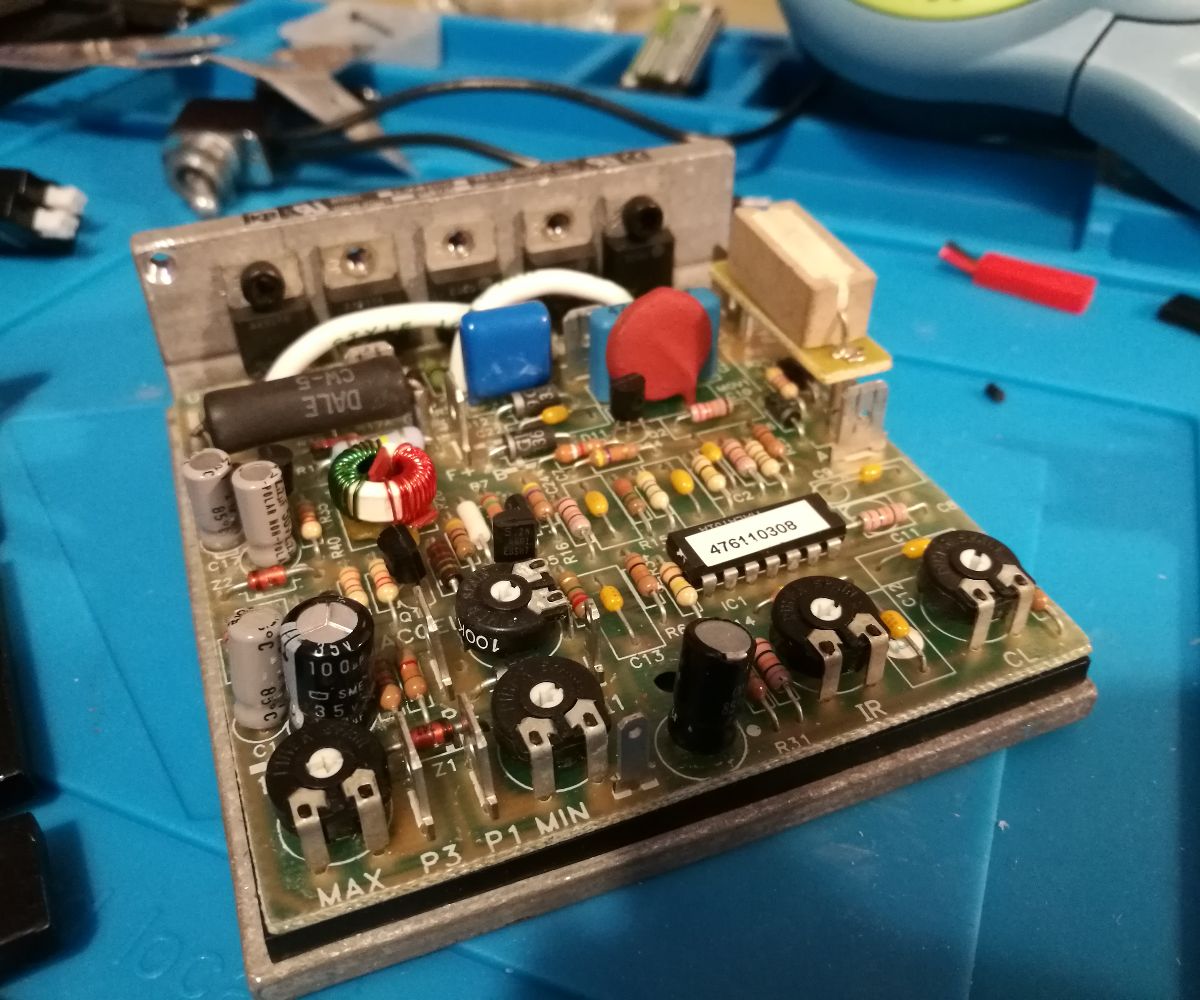

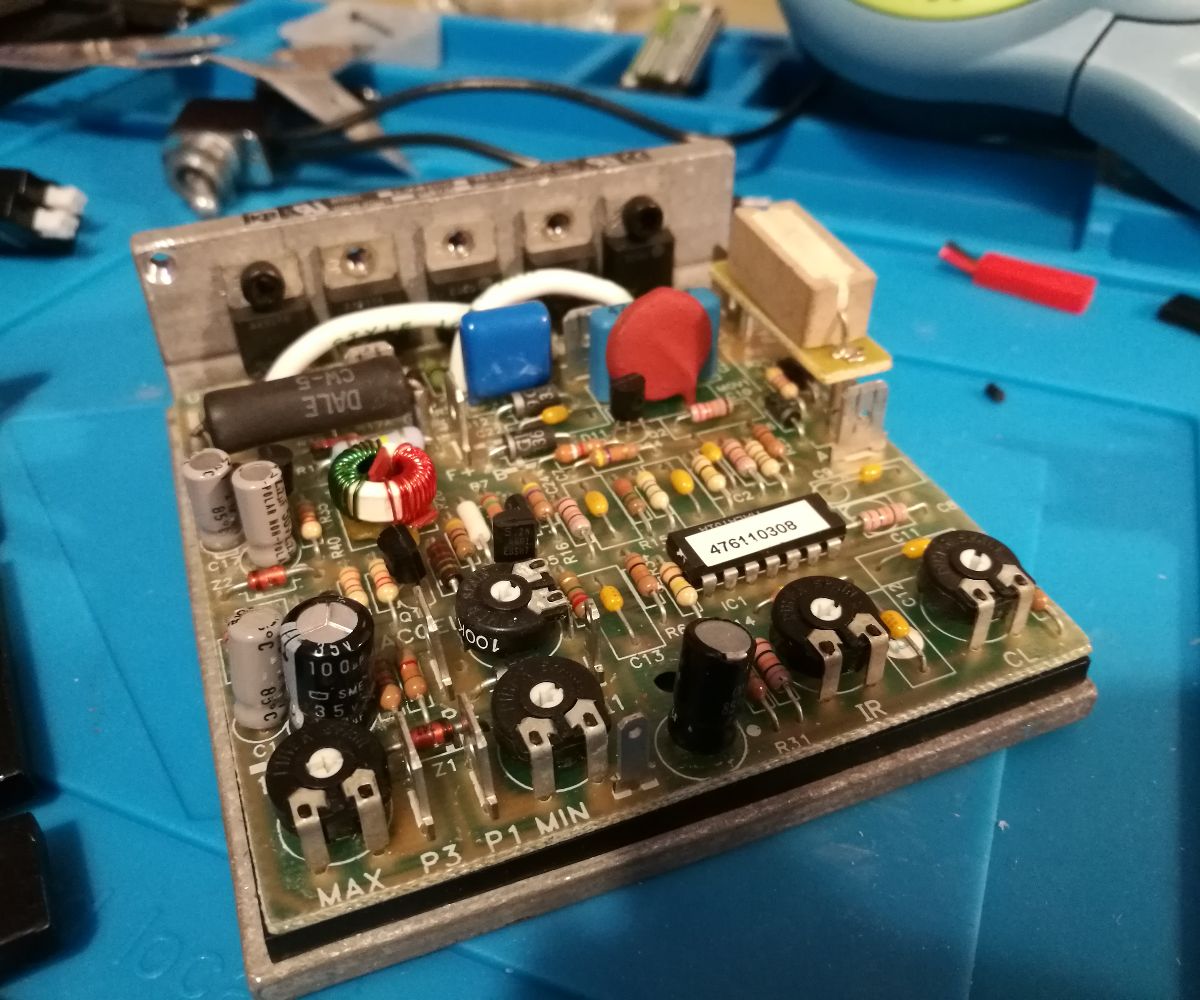

Here is the old speed control board, 1980s electronics, a bit faded but looked good despite shorting all the time when powered.

After a bit of hunting online, turns out they still produce a version of this board. Here was the best source for me. Just has to pick the right HP resistor, which for a sherline lathe is the 0.015 Ohm Horsepower Resistor.

https://www.axiscontrols.co.uk/prod...ic-range/kbic-240ds-dc-motor-speed-controller

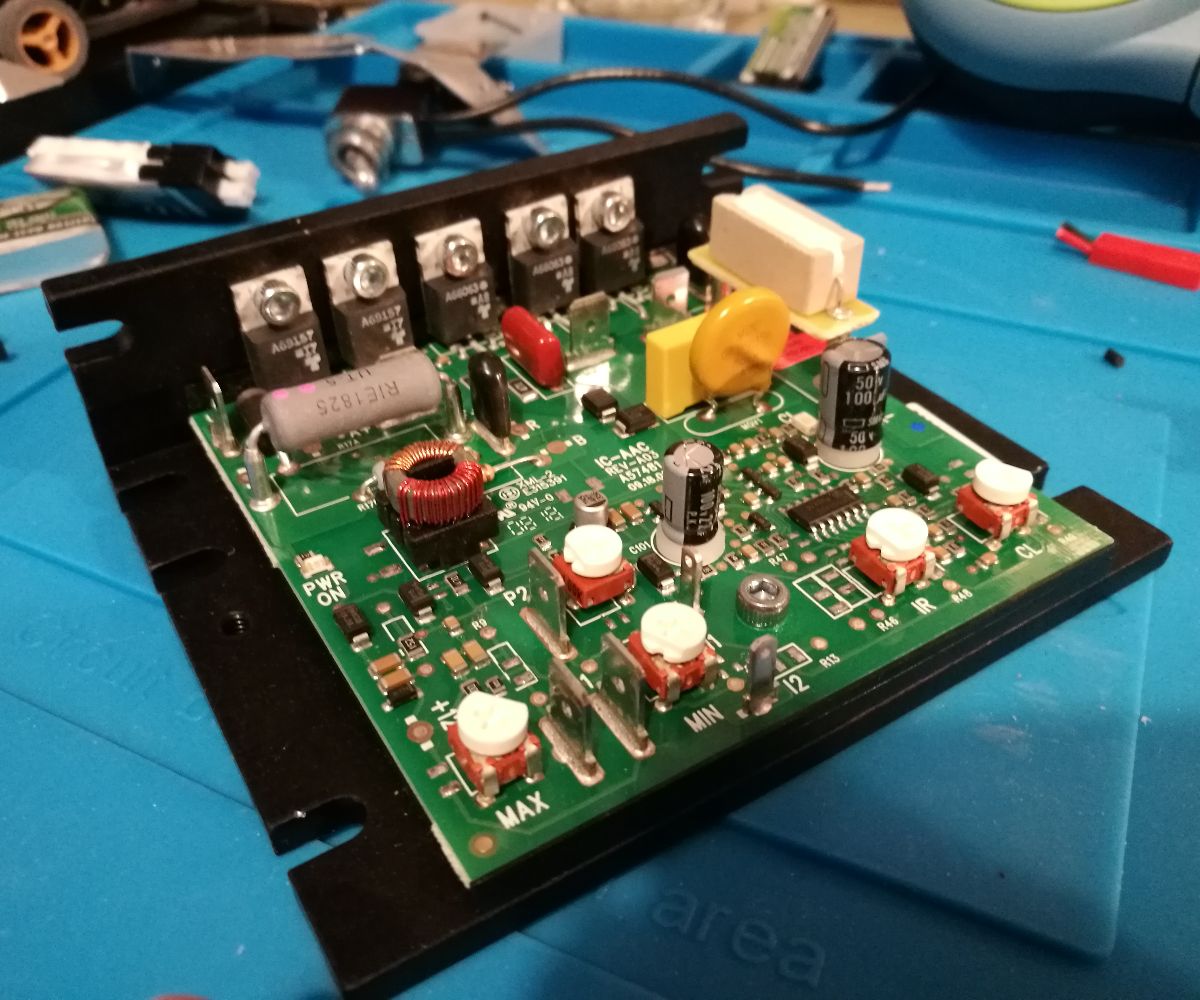

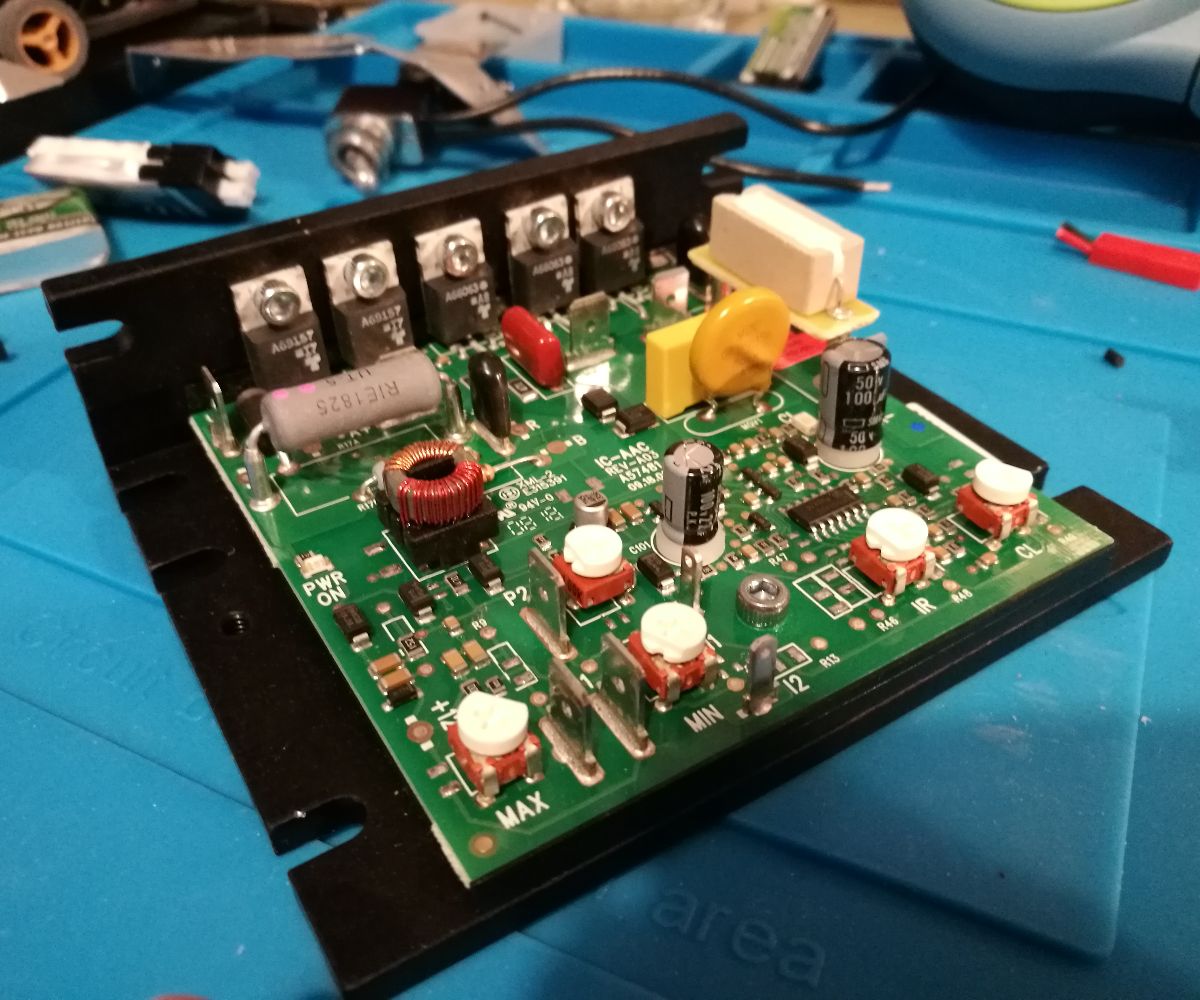

Here is the new board, does the same thing, but it just amazed me how much smaller all the same components are 35 years later. LEDs to show warnings and everything.

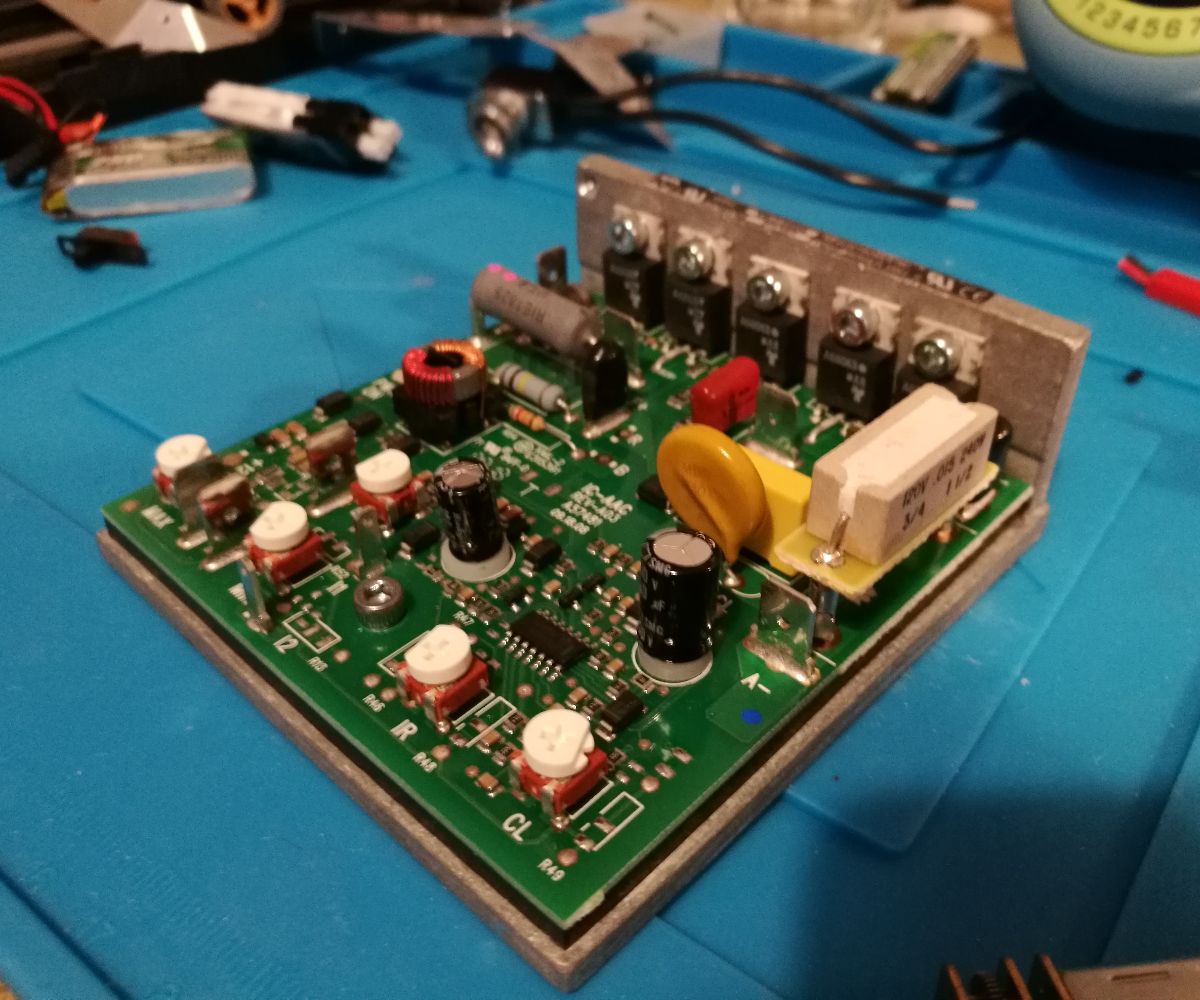

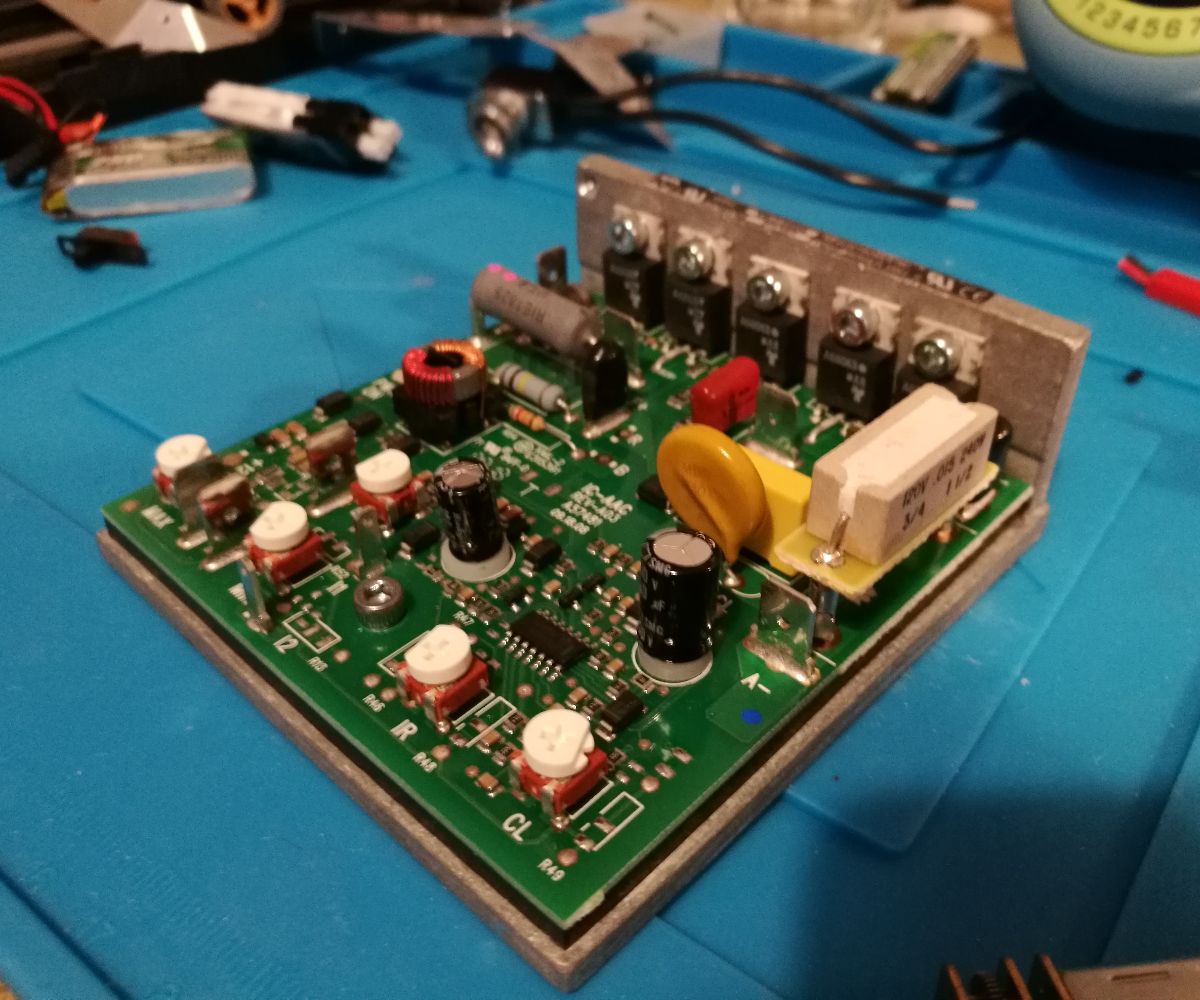

Seated in the old housing for the old board.

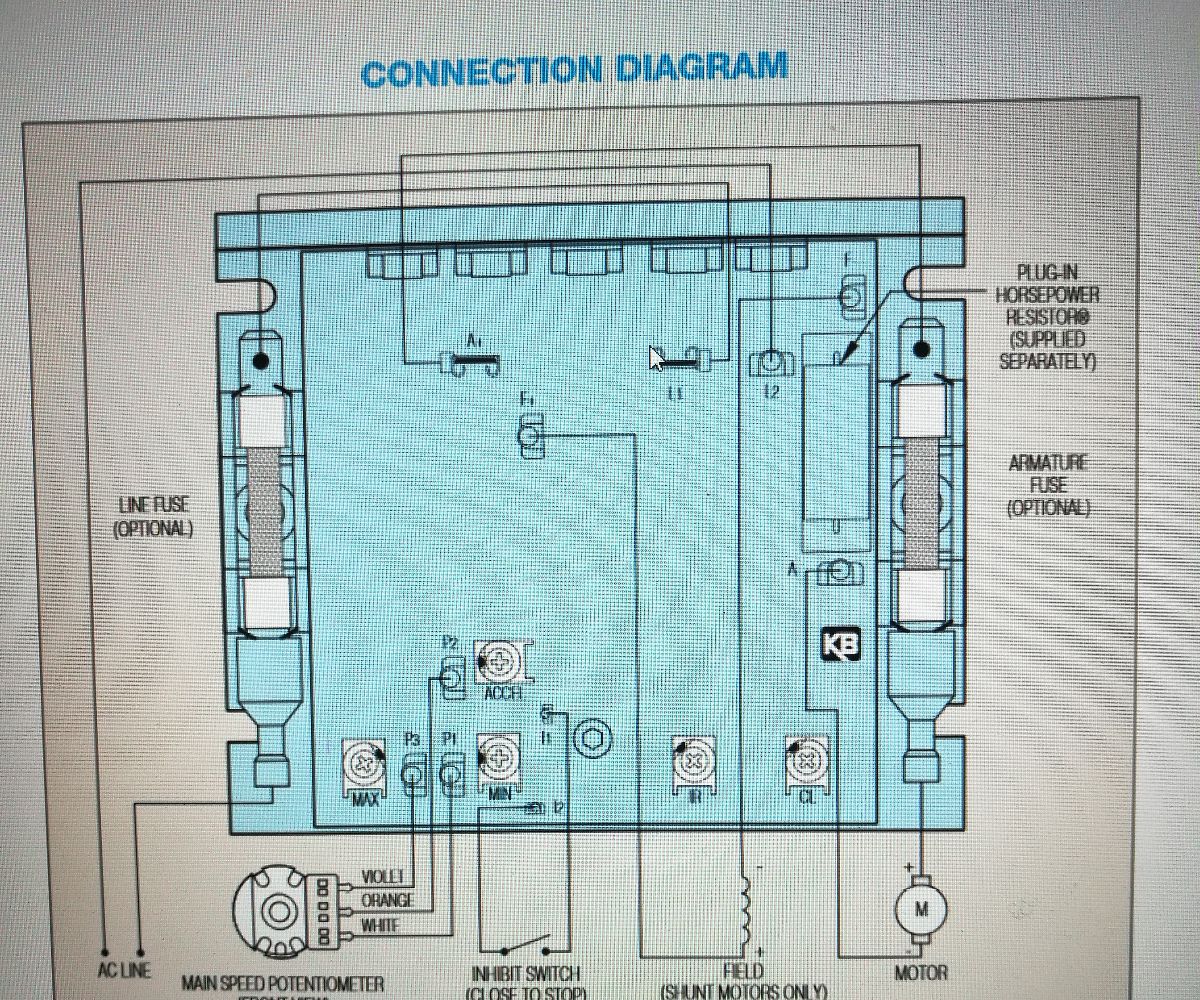

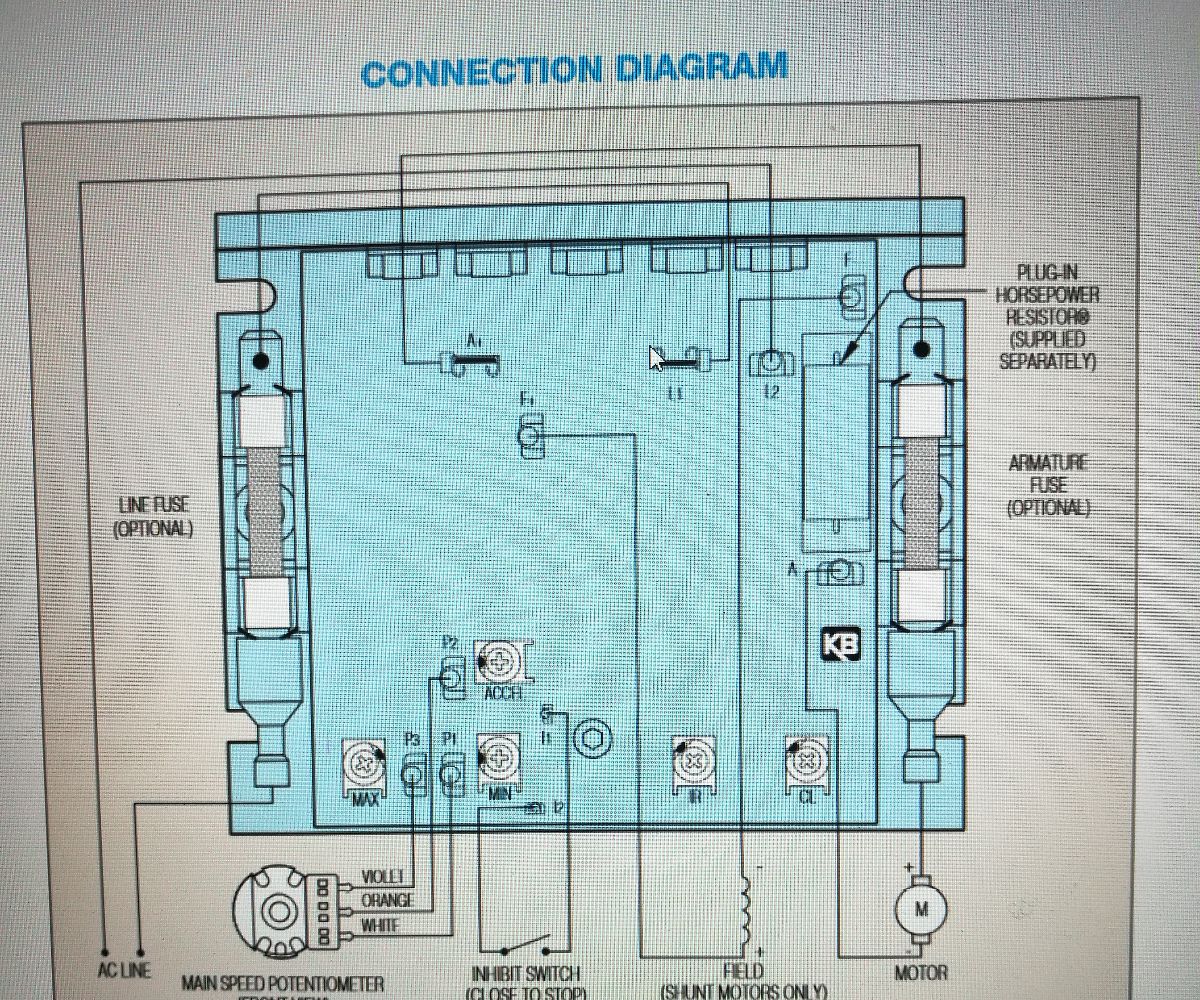

Wiring Diagram to wire it back up to the sherline.

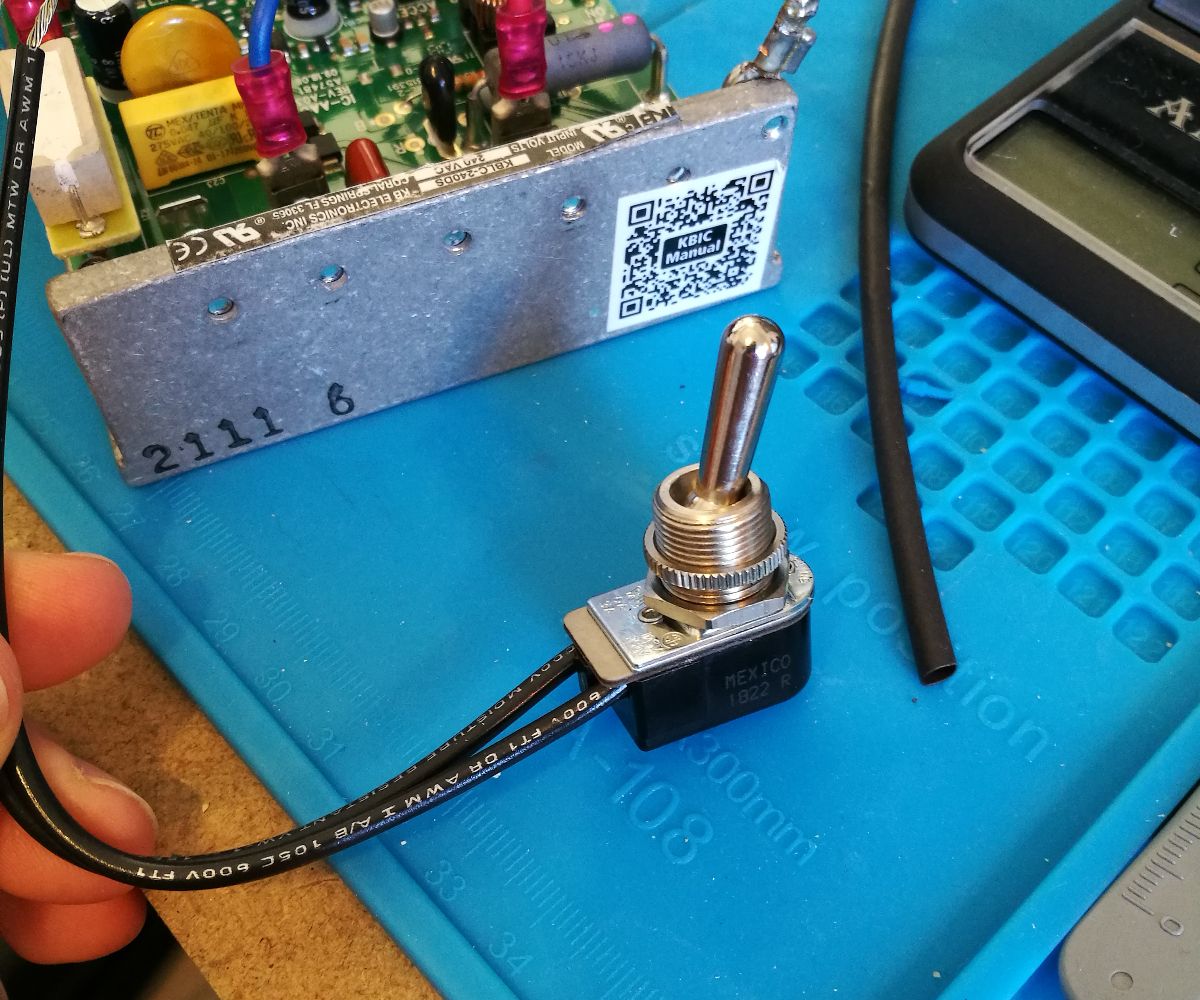

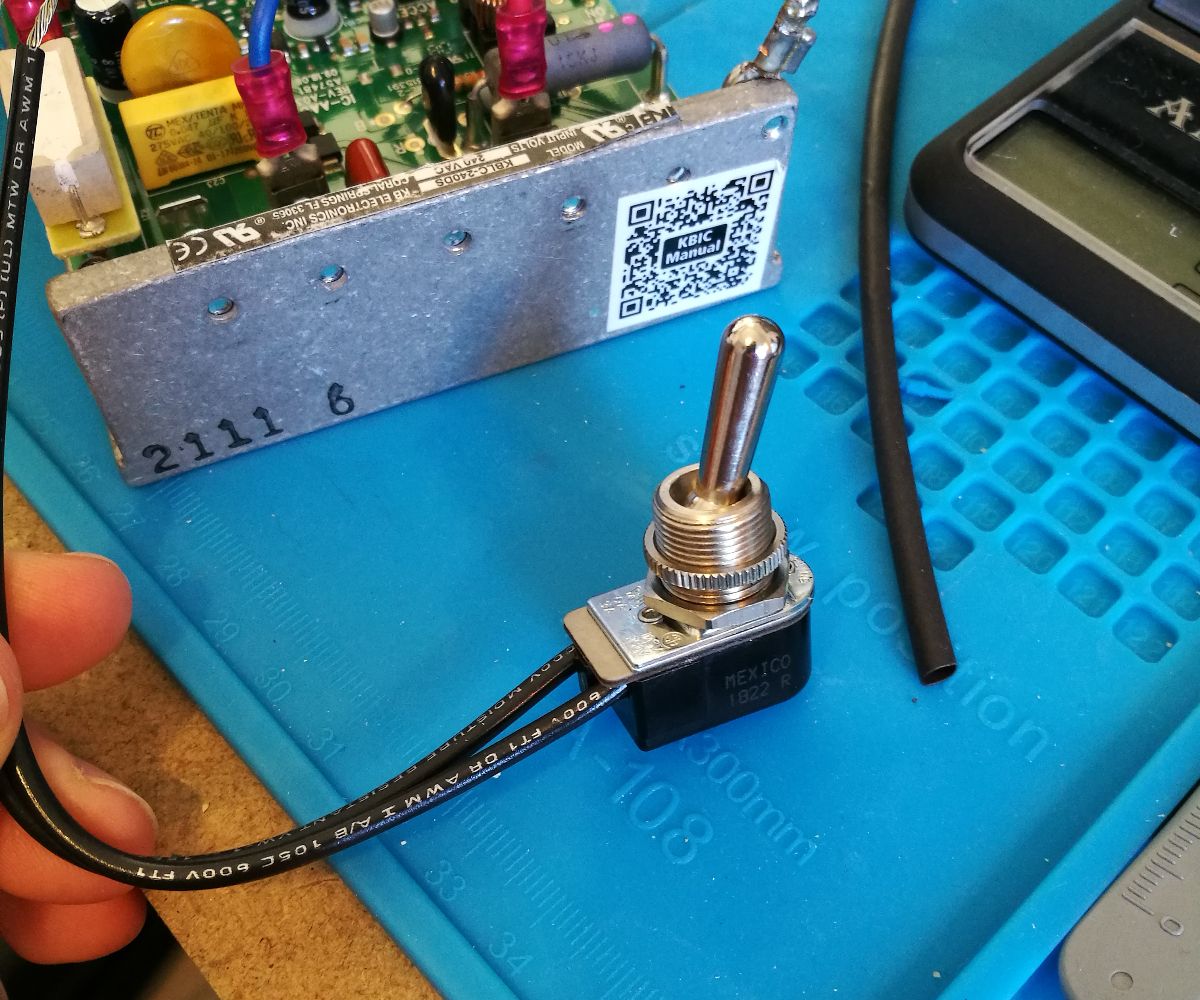

Picked up a new switch for on and off. Then reassembled.

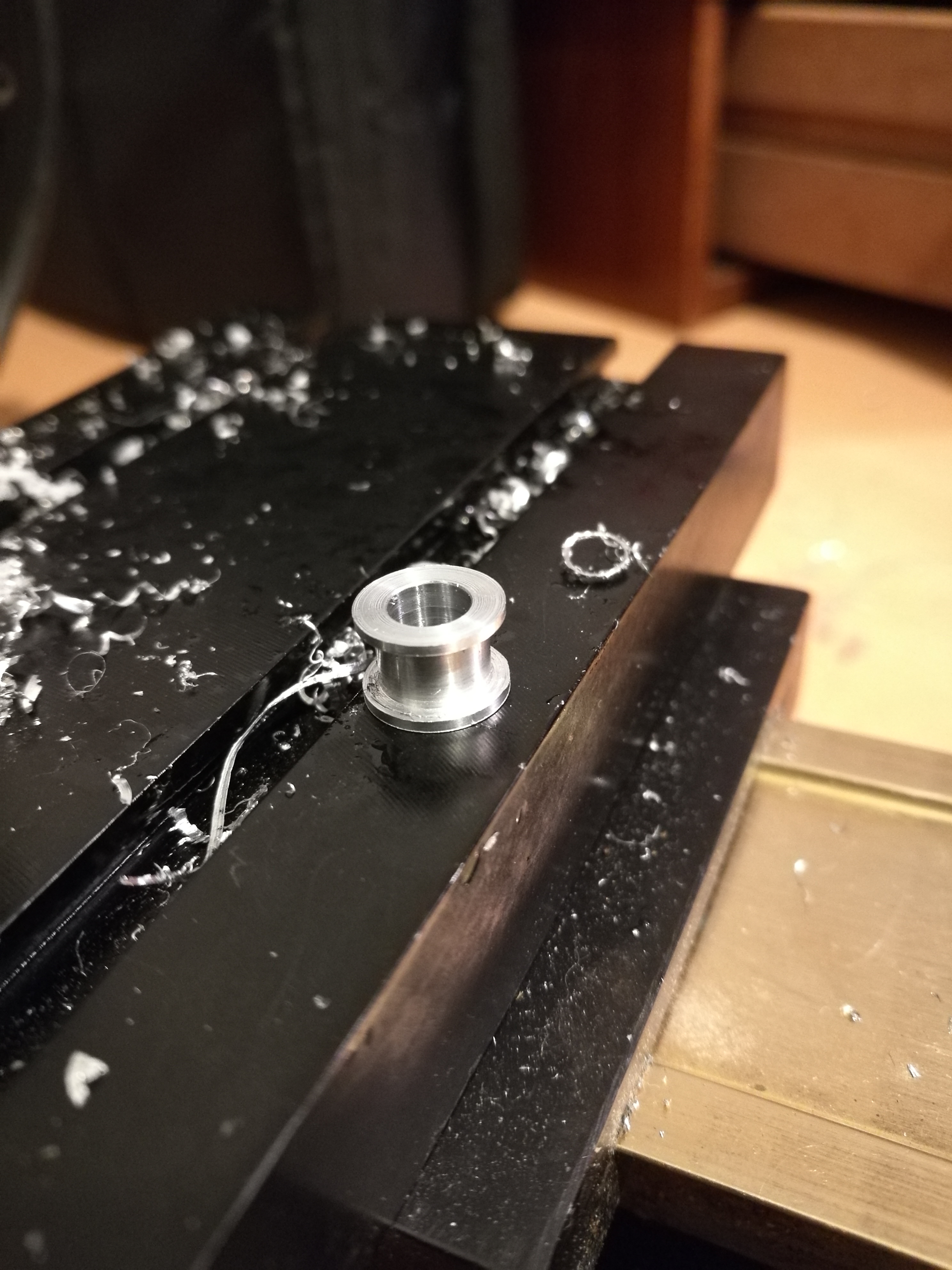

Results I am pleased with, so far. The motor spins down and up nice and smoothly, goes down to practically 50RPM and I have been practicing with steel and alu.

Still a way to go yet, but I am enjoying starting to learn how to use a lathe with the repaired sherline

It's a fair bit older than me, being brass. But it seems well aligned still and I have been having good fun learning with it.

When it arrived, the motor was broken, brushes had burnt down and filled it with black soot. The switch was worn out and corroded inside so it would not turn on. And the control board would short out despite me disconnecting anything, checking the components...

So fixing time!

It was a bit of a pain to find the right components, I guess I could have bought a new speed control assembly from sherline. But this was cheaper and the same result. I hunted for a while for some material online about swapping the electronics on an old sherline. No luck, so maybe this post helps to guide someone else at one point!

First I had to disassemble the problem end, here is what is left after removing the electronics and motor.

I opened up the motor and cleaned it out, reseated the brushes. The bearing could do with replacing as it clicks per rotation. I'll fix that if it gets too bad. Didnt photo this step

Here is the old speed control board, 1980s electronics, a bit faded but looked good despite shorting all the time when powered.

After a bit of hunting online, turns out they still produce a version of this board. Here was the best source for me. Just has to pick the right HP resistor, which for a sherline lathe is the 0.015 Ohm Horsepower Resistor.

https://www.axiscontrols.co.uk/prod...ic-range/kbic-240ds-dc-motor-speed-controller

Here is the new board, does the same thing, but it just amazed me how much smaller all the same components are 35 years later. LEDs to show warnings and everything.

Seated in the old housing for the old board.

Wiring Diagram to wire it back up to the sherline.

Picked up a new switch for on and off. Then reassembled.

Results I am pleased with, so far. The motor spins down and up nice and smoothly, goes down to practically 50RPM and I have been practicing with steel and alu.

Still a way to go yet, but I am enjoying starting to learn how to use a lathe with the repaired sherline