When I built the inside out radial "improbability drive" it was for puzzle value (to tease friends, family and aquaintances) - unfortunately the nett result was pug ugly (I have a pug).

The local expression is "skreeulelik" which roughly translates into "screaming ugly".

So its not going on display as such - but it got me to thinking if I could come up with a more elegant inside out version.

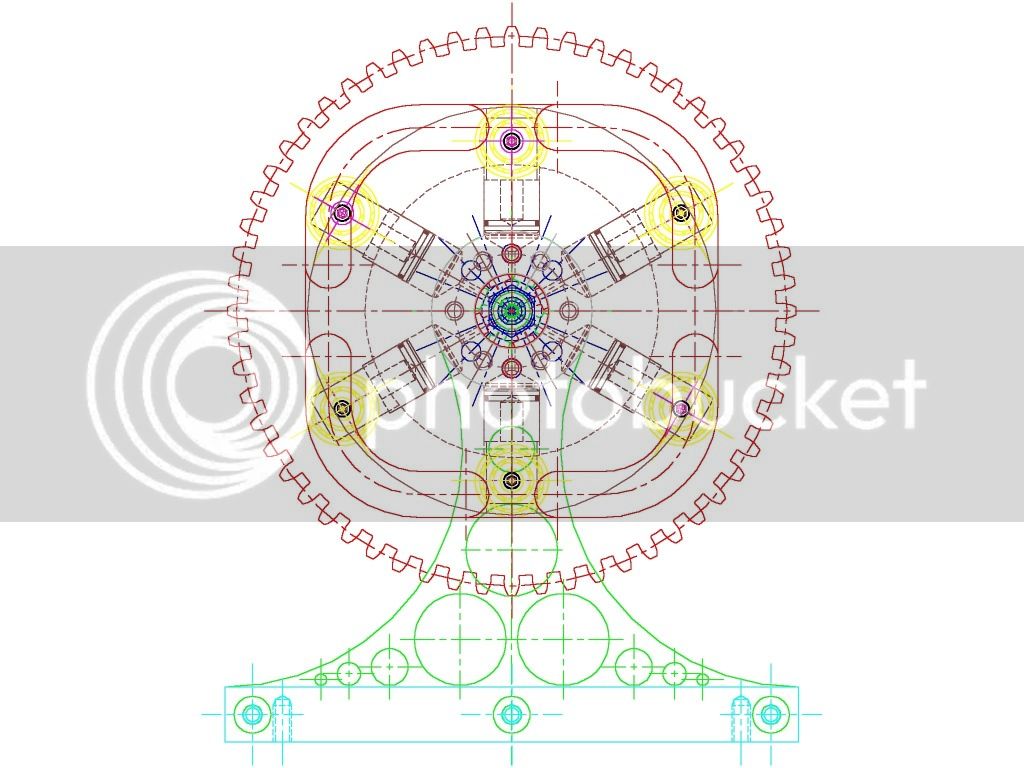

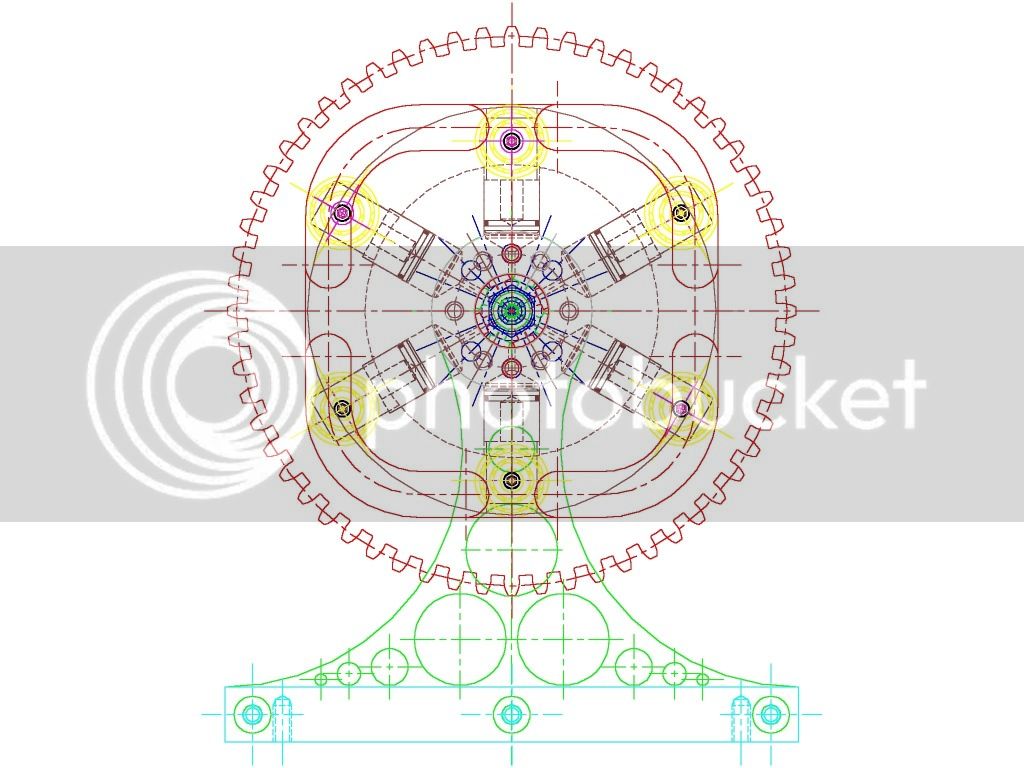

This is it :-

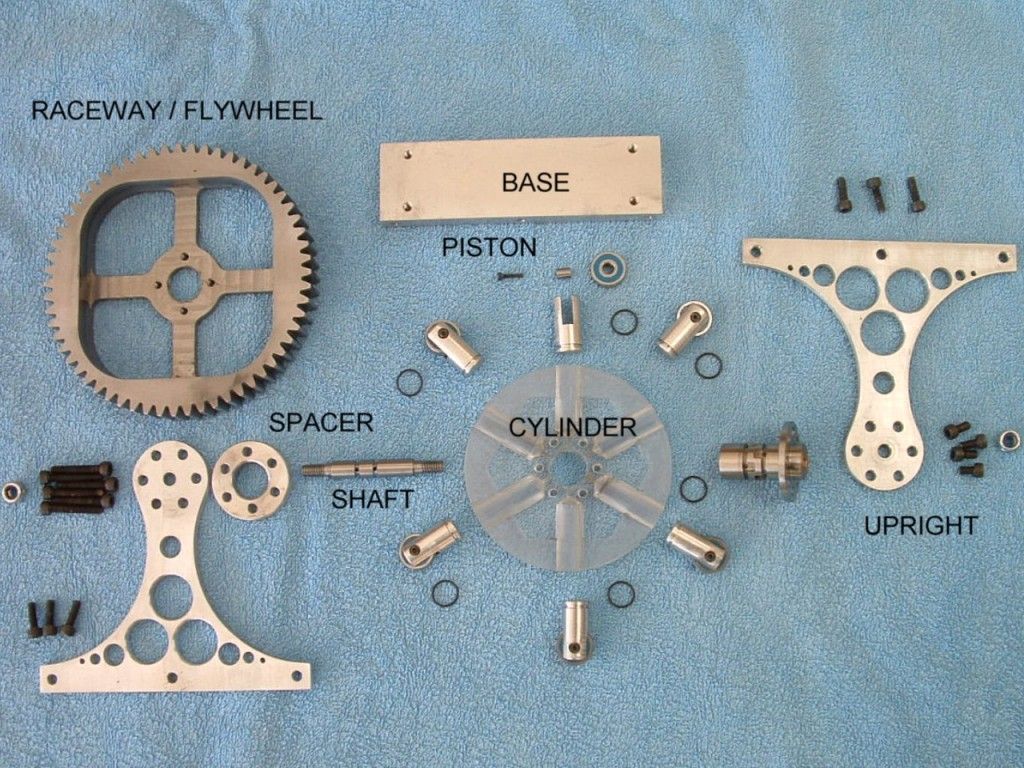

A self propelling gear

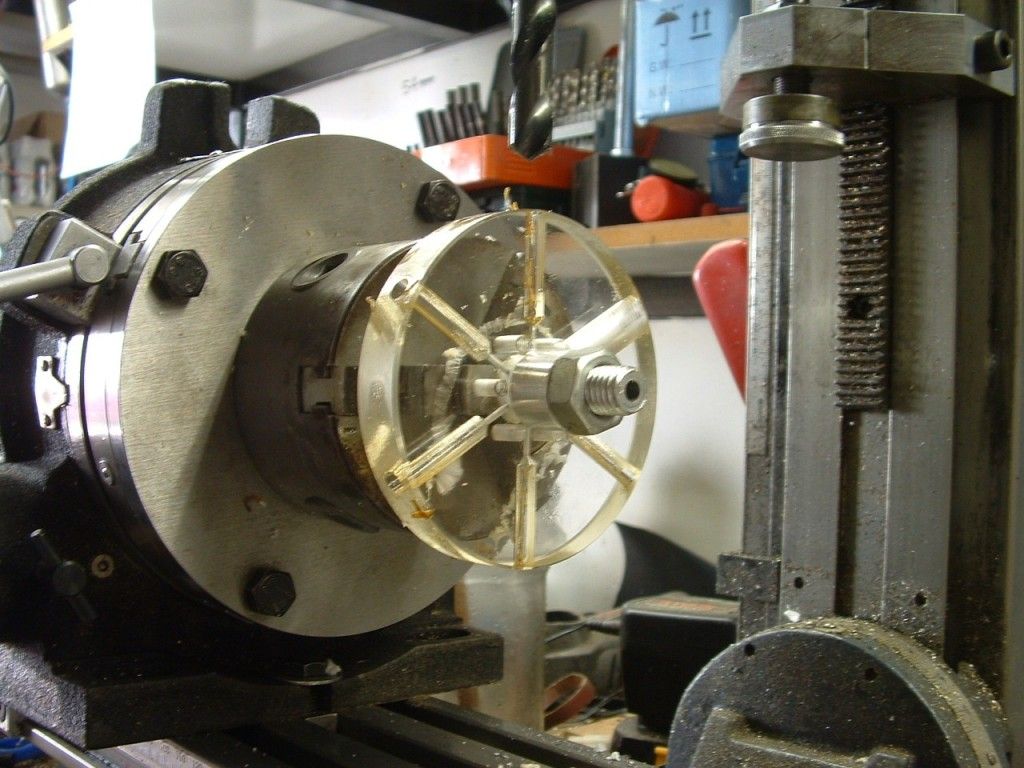

I've just finished building it and its running itself in (or to destruction - whichever comes first) out in the shop.

The gear is simply bling - or if you like the raw material for the flywheel.

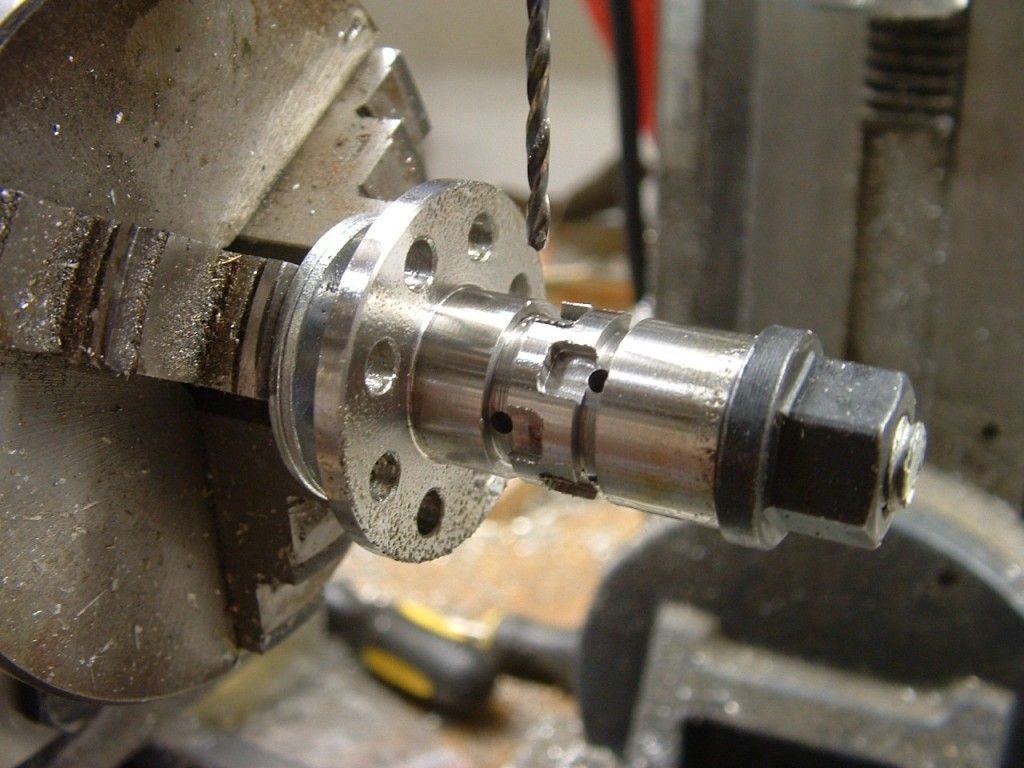

If I design something I don't post on it until it at least looks like its going to work - so my work in progress posts are often a bit ass-backwards.

I will post a video and some progress photos shortly.

Any bright ideas on what to call it ?

Ken

The local expression is "skreeulelik" which roughly translates into "screaming ugly".

So its not going on display as such - but it got me to thinking if I could come up with a more elegant inside out version.

This is it :-

A self propelling gear

I've just finished building it and its running itself in (or to destruction - whichever comes first) out in the shop.

The gear is simply bling - or if you like the raw material for the flywheel.

If I design something I don't post on it until it at least looks like its going to work - so my work in progress posts are often a bit ass-backwards.

I will post a video and some progress photos shortly.

Any bright ideas on what to call it ?

Ken