BobWarfield

Well-Known Member

- Joined

- Dec 27, 2007

- Messages

- 1,151

- Reaction score

- 1

Was out in the shop working on Ye Olde Team Build, specifically, the flywheels. I put together a little polishing rig and got curious about a couple of the wheels that did not pass "inspection". Their diameter was more than 5 thousandths over, which I'd set as my inspection limit for the project. I doubt it matters much if they were 10 instead of 5 or less, but what the heck.

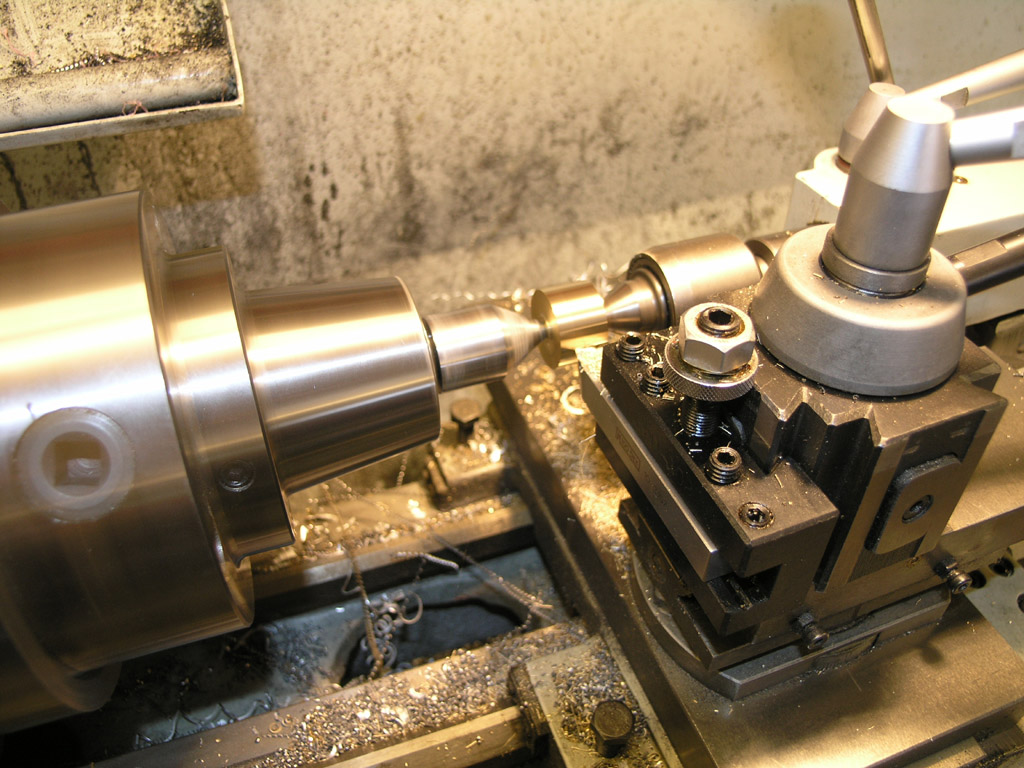

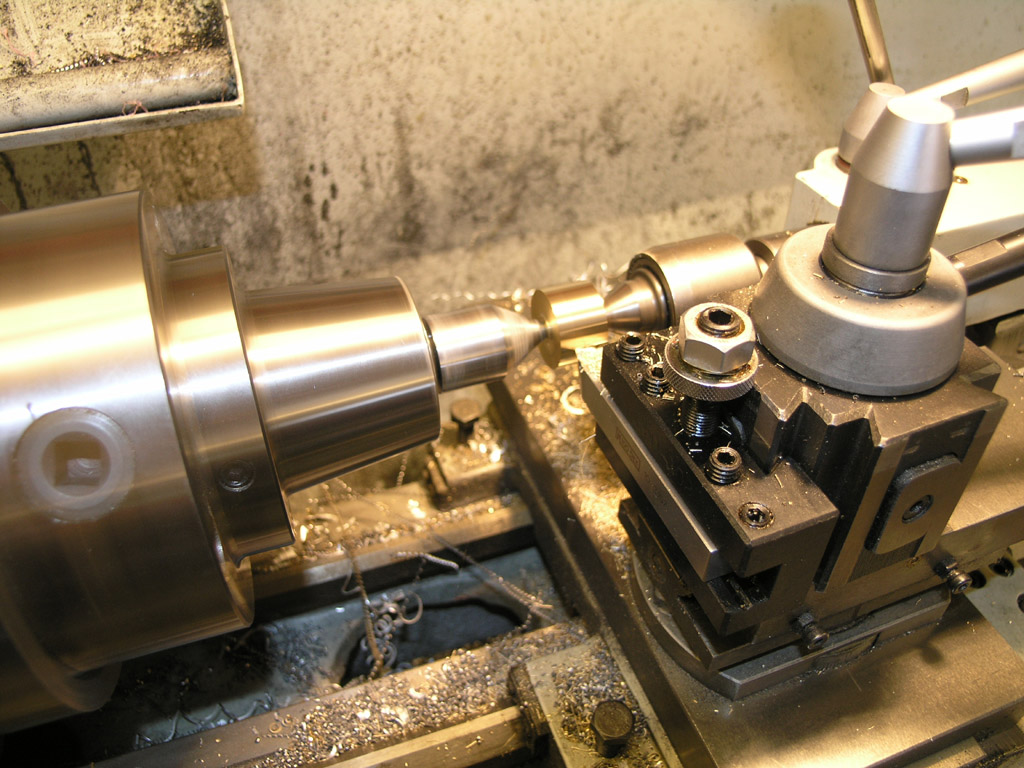

So, as I was pondering how best to turn down some nearly finished flywheels, I remembered Bogstandard's post on making flywheels from plate where he suspended them between a chuck with tape on the jaws and a live center. Maybe I could do this too, only using a couple centers and no lathe dog. After all, I wouldn't want to mar my little flywheel up or damage its carefully reamed bore.

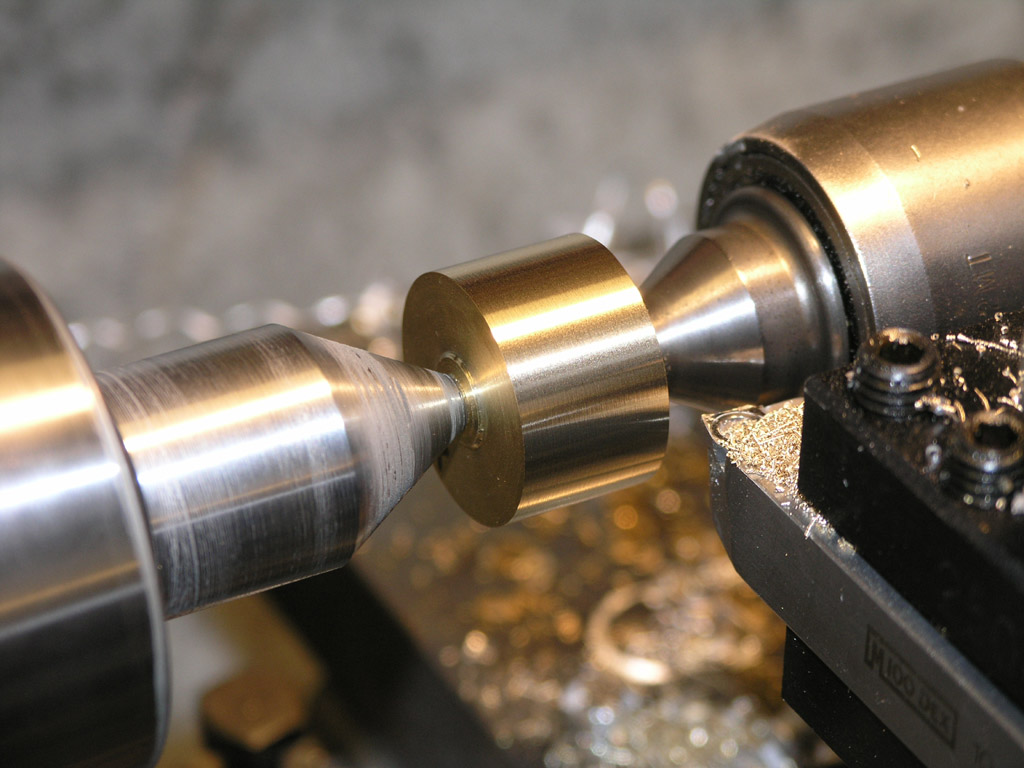

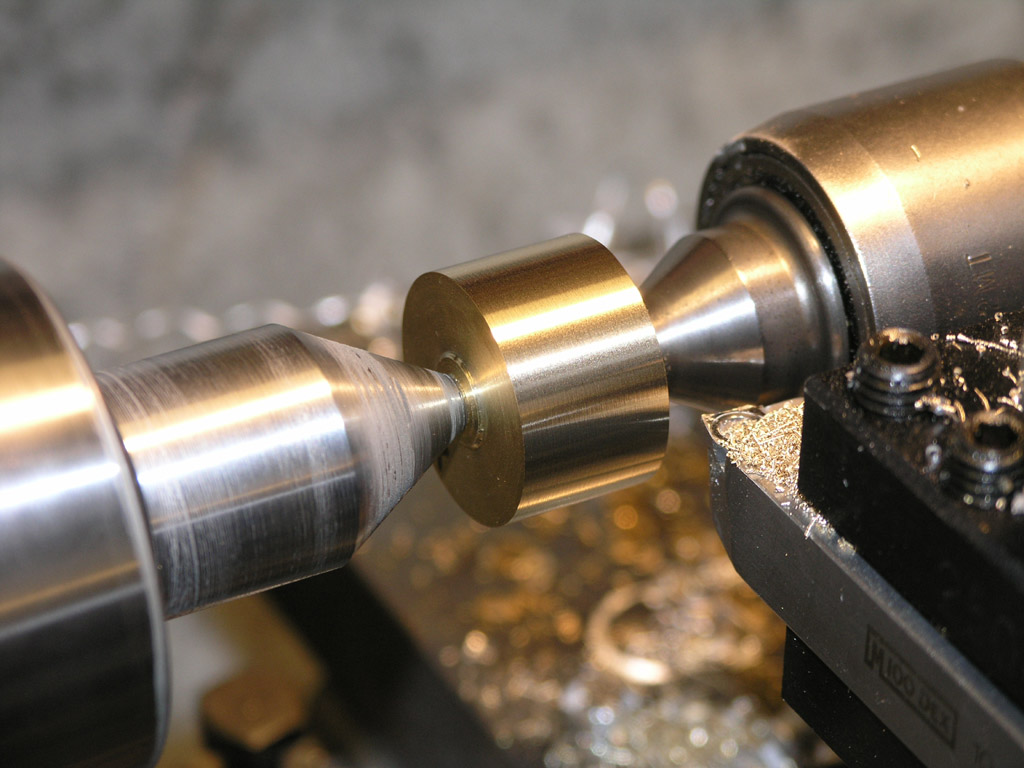

I tried a piece of chamoise and sandpaper to help the thing to get traction ala Bogstandard's masking tape, but it turned out not to help and not to be necessary. I made the center that's in the collet chuck as part of the project as well, but it's dead easy. It's just a hole popper with a 1/2" shank.

I found I could turn 0.002" off (0.004" on the diameter) without slipping:

The finish came out very nice with a brand new sharp aluminum cutting insert (sharp edges even though its carbide) and my slowest feedrate:

The junk on the centers is residue from polishing the other flywheels. I will show more how they came out when I get them all done by posting a "start to finish" thread in the team build section.

Thanks to Bogstandard for inspiring the idea!

Cheers,

BW

So, as I was pondering how best to turn down some nearly finished flywheels, I remembered Bogstandard's post on making flywheels from plate where he suspended them between a chuck with tape on the jaws and a live center. Maybe I could do this too, only using a couple centers and no lathe dog. After all, I wouldn't want to mar my little flywheel up or damage its carefully reamed bore.

I tried a piece of chamoise and sandpaper to help the thing to get traction ala Bogstandard's masking tape, but it turned out not to help and not to be necessary. I made the center that's in the collet chuck as part of the project as well, but it's dead easy. It's just a hole popper with a 1/2" shank.

I found I could turn 0.002" off (0.004" on the diameter) without slipping:

The finish came out very nice with a brand new sharp aluminum cutting insert (sharp edges even though its carbide) and my slowest feedrate:

The junk on the centers is residue from polishing the other flywheels. I will show more how they came out when I get them all done by posting a "start to finish" thread in the team build section.

Thanks to Bogstandard for inspiring the idea!

Cheers,

BW