You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question for the Cracker builder

- Thread starter jim_geib

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

vlmarshall

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 1,138

- Reaction score

- 1

It'll run! Add an oil groove or two to your piston, and think about making a displacement oiler, and you'll be quite happy... but it'll work like it is.

Post some pictures, there's no "Cracker Skunk Works"! ;D

vlmarshall

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 1,138

- Reaction score

- 1

There ya go, the voice of experience. HIS is done. ;Dshred said:I'd try it as-is. If it doesn't work well enough later on, put an o-ring groove in it and o-ring it.

Thanks everyone, I am going to go with. If I have to make a new one I guess it doesn't matter when I make it.

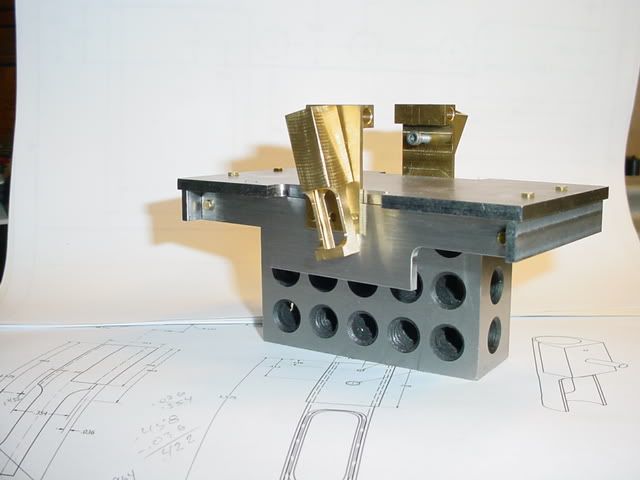

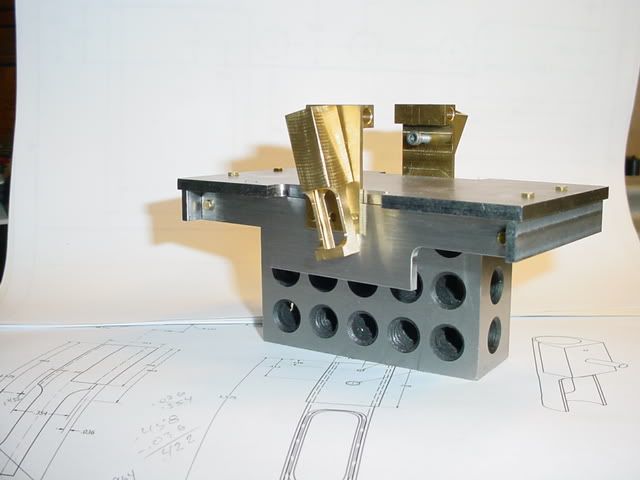

This is what I have done sofar,

I wanted to wait and get a little farther alone before posting any photos. I am trying something a little different and adding a second cylinder on the other side. Don't know if it will work or not, but it is fun making the parts. I am making the piston out of stainless steel, this is the first time I have turned anything out of stainless and I just went a little to far.

Also what did you use for springs to hold the cylinder in place, did you start with a common spring, like from a ball point pen.

Thanks again everyone

Jim Geib

This is what I have done sofar,

I wanted to wait and get a little farther alone before posting any photos. I am trying something a little different and adding a second cylinder on the other side. Don't know if it will work or not, but it is fun making the parts. I am making the piston out of stainless steel, this is the first time I have turned anything out of stainless and I just went a little to far.

Also what did you use for springs to hold the cylinder in place, did you start with a common spring, like from a ball point pen.

Thanks again everyone

Jim Geib

vlmarshall

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 1,138

- Reaction score

- 1

Nice! I like the twin-cylinder idea, like the original Byers. I almost did the same, I would have cut the middle out of the footplate to make room for a long, but small-diameter, flywheel between the frames.

For the cylinder springs, I just dug through my spring bin until I found a pair that were suitable, mine are held in place with a nut, so I can adjust the tension a bit.

I know what you mean about photos; I waited a while myself. I can't compete with the modellers on here!

For the cylinder springs, I just dug through my spring bin until I found a pair that were suitable, mine are held in place with a nut, so I can adjust the tension a bit.

I know what you mean about photos; I waited a while myself. I can't compete with the modellers on here!

Vernon,

I think I read somewhere on here that the cylinder should start to blow by the cylinder and the plate at about 25-30lbs, so that is what I was going to shot for.

I can only hope to for a project to look half as nice as the master work I see here, I look at what you'all have done and it gets me thinking that my work will get better. It is great to have someplace to pick the masters minds.

I think I read somewhere on here that the cylinder should start to blow by the cylinder and the plate at about 25-30lbs, so that is what I was going to shot for.

I can only hope to for a project to look half as nice as the master work I see here, I look at what you'all have done and it gets me thinking that my work will get better. It is great to have someplace to pick the masters minds.

vlmarshall

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 1,138

- Reaction score

- 1

bearcar1 said:I'm likin' the twin idea. Day dreamed about doing that very same thing for a while but that's about as far as I got.

Do it, Bearcar! Or go the other way, a single cylinder, double-acting Cracker. Reverse would be nice. If I ever repower one of mine I'll go that way.

Jim-Geib, the bit about wobblers blowing off the seat as a second safety seems to be a myth, several loco builders in the 16mm group have mentioned it, and something about an old commercial loco, possibly a Mamod, that started that rumor as a selling point. I guess it needs testing... not too difficult with a regulator.

Looks interesting. If you offset the power strokes you may be able to get by without a flywheel; that would help a lot. IIRC one of the original 'Cricket's (a very similar design) was made with two cylinders and a bit of info on it is on the web.

Shred,

I was looking at the "Ideas" to build and did not like the overall look of it. the Cracker has more of the "Thomas The Tank Engine" look. I am going to quarter the the crank and hoope for a self starter. All the Cracker builds here has given me the inspration to give this a try, I am slow as I only get about one hour a night in the shop.

Jim

I was looking at the "Ideas" to build and did not like the overall look of it. the Cracker has more of the "Thomas The Tank Engine" look. I am going to quarter the the crank and hoope for a self starter. All the Cracker builds here has given me the inspration to give this a try, I am slow as I only get about one hour a night in the shop.

Jim

To carry the 'ideas' stage a bit further, and also to throw more fuel on the imagination fire, I had done some very rudimentary sketches of a twin Cracker engine in a 0-4-2 or a 0-6-2 configuration. ??? It would be a bit longer obviously th_confused0052 (yes, size DOES matter ;D) but would lend another dimension to the "interpretation" or variation of a theme to the model. Oh, isn't it fun to sit around and devise such contraptions? :big: A by product of having way too much available time on ones disposal.

BC1

Jim

BC1

Jim

vlmarshall

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 1,138

- Reaction score

- 1

It sure is! I went through several ideas for modifications, before I realized that I'm going to be building a lot more locomotives... so I'll save the changes for those models. ;DBMyers said:Very Cool. This engine sure is great for builder interpretation.

I finished the turning on the first rod, put two small groves in the piston end. Won't have to call it a ashtray(Bill Cosby)

Photo shows the stainless bolt I started with. If I'm lucky I'll get the turning on the second one done tomorrow night. Then I can setup the mill and do the conrod ends.

Photo shows the stainless bolt I started with. If I'm lucky I'll get the turning on the second one done tomorrow night. Then I can setup the mill and do the conrod ends.

vlmarshall

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 1,138

- Reaction score

- 1

Looks great so far, nice source of stainless steel!

Are they your own version of the plans I see?

Are they your own version of the plans I see?

I built it first in Autodesk Inventor first, or I guess I should say as I go along.

View attachment Cracker.bmp

View attachment Cracker.bmp

View attachment Cracker.bmp

View attachment Cracker.bmp

Similar threads

- Replies

- 39

- Views

- 4K

- Replies

- 12

- Views

- 784