You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Profiling Tools

- Thread starter ironman

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Is this what you are looking for?

http://glanze.com/indexable-tool-holders/mc-tc-prdnn-prgnr.html

Here's a link for the UK: http://www.glanze.co.uk/acatalog/Lathe_Profiling_Tools.html

I think any dealer that handles Glanze should be able to supply this to you.

I looked around on the net for a US reference to the specific tool but didn't find one. Perhaps Grizzly could supply?

http://glanze.com/indexable-tool-holders/mc-tc-prdnn-prgnr.html

Here's a link for the UK: http://www.glanze.co.uk/acatalog/Lathe_Profiling_Tools.html

I think any dealer that handles Glanze should be able to supply this to you.

I looked around on the net for a US reference to the specific tool but didn't find one. Perhaps Grizzly could supply?

- Joined

- Dec 28, 2008

- Messages

- 1,731

- Reaction score

- 9

ironman said:I have seen photos of people using a round insert on their lathe for a betrter finish. Can someone direct me to a company that sells the Tool Holder and Round Inserts? Thanks in advance. ironman

Are you referring to is round inserts like RPMY or RPMW? If so, these are 'non-standard' inserts that are usually expensive and difficult to come by. My understanding is that their used to create profiles using CNC equipment. And their lack of availability seems to say that they have a specific purpose not related to getting a better finish on a lathe turned surface.

To get a 'better finish' a small radius ground on the tip of a cutter will do the trick, and if you want to use throw away inserts there are plenty to choose from that are designed with a radius to accomplish this goal.

This is just my opinion, I'm not trying to discourage you. I did a little searching around for the holders and inserts, and they are 'scarce' to say the least. Something worth considering.

-MB

- Joined

- Dec 28, 2008

- Messages

- 1,731

- Reaction score

- 9

ironman said:Thanks MB for your reply. Do you mean like a 1/32 or 1/64 radius? That is what I have on my triangular TCMT inserts. Maybe I just don't have them exactly on centere. I will check that out. Have a great day. ironman

Yes, That's exactly what I mean. TCMT inserts are a good way to go. On hand ground carbide tooling (brazed on tips) you could even experiment with a slightly larger radius, as long as it doesn't create 'chatter'. There could be a lot of reasons that can cause a poor turned finish. Tool rigidity, geometry, and height is something to look at, along with speed and feed. I have great deal of difficulty with getting a nice finish on cold rolled steel. Drives me nuts!

-MB

In the US you should be able to get them from MSC

insert Its the small RCMT 0602 that the Glanze hobby tooling mostly has

http://www1.mscdirect.com/CGI/GSDRVSM?PACACHE=000000168558828

holder, the ISO ref is SRDCN

http://www1.mscdirect.com/CGI/NNSRIT?PMPXNO=1961991&PMT4NO=100650417

Jason

insert Its the small RCMT 0602 that the Glanze hobby tooling mostly has

http://www1.mscdirect.com/CGI/GSDRVSM?PACACHE=000000168558828

holder, the ISO ref is SRDCN

http://www1.mscdirect.com/CGI/NNSRIT?PMPXNO=1961991&PMT4NO=100650417

Jason

Bogs' short reply #1 to this post is instructive: http://madmodder.net/index.php?topic=3747.0

Ironman: Would a 12mm tool as shown in the link Bogs posted work for you?

Ironman: Would a 12mm tool as shown in the link Bogs posted work for you?

I ordered a Glanz 12 MM profiling tool and inserts from Chronos in the UK, and had it shipped to me here in the U.S. Shipping was not bad- I think around $15. Chronos' website is here:

http://www.chronos.ltd.uk/

Search on "Glanz profiling tool."

http://www.chronos.ltd.uk/

Search on "Glanz profiling tool."

Just so you know the Glanze.co.uk site is also part of Chronos as they are the UK agents, some of the things that were on Chronos site are now only on their Glanze site so you may need to look at both to find what you want.

J

J

Hi Ironman

I pick them up at shows fairly cheaply. They come in all sorts of strange shapes. the following picture shows a few of mine. I had to make up the holders to suit. I try to buy at least 5 or 6 so its worth while making them.

This next shot shows me using one to give a bit of shape to a funnel cap.

Cheers

Rich

I pick them up at shows fairly cheaply. They come in all sorts of strange shapes. the following picture shows a few of mine. I had to make up the holders to suit. I try to buy at least 5 or 6 so its worth while making them.

This next shot shows me using one to give a bit of shape to a funnel cap.

Cheers

Rich

Also in the UK, but they export to US with no problems.

http://rdgtools.co.uk/acatalog/PROFILE_LATHE_TOOLS.html

Go down a bit on here for tips.

http://rdgtools.co.uk/acatalog/Tips_sold_by_box_of_10.html

http://rdgtools.co.uk/acatalog/PROFILE_LATHE_TOOLS.html

Go down a bit on here for tips.

http://rdgtools.co.uk/acatalog/Tips_sold_by_box_of_10.html

I bought a 6mm one from a retailer in the US [New England Brass and Tool]. Here's what I said about it at the time (and is still true): [bizzarely; it appears in the middle of some totally different thread]: http://www.homemodelenginemachinist.com/index.php?topic=1647.msg59213#msg59213

My current favorite is a somewhat larger (10mm?) left-handed one I got off eBay (Bogs-tip: the lefty tools can be installed like this and are frequently much less sought-after than the righty ones). These larger sizes are used in CNC lathe work, so they come up every so often. I use this one all the time-- it's my primary facing and turning tool (it does need some HP to take a big cut, so a smaller one might be more appropriate for <10" lathes)

My current favorite is a somewhat larger (10mm?) left-handed one I got off eBay (Bogs-tip: the lefty tools can be installed like this and are frequently much less sought-after than the righty ones). These larger sizes are used in CNC lathe work, so they come up every so often. I use this one all the time-- it's my primary facing and turning tool (it does need some HP to take a big cut, so a smaller one might be more appropriate for <10" lathes)

Sorry about that IM, I use the 6mm tips with those units, but I do have another that uses a special 10mm.

The main reason I use this type is because when you have rotated the tip say a dozen or so times and it is then blunt all the way around, but not damaged, I swipe the top surface over a diamond lap, and they are then reusable on materials that require zero top rake, brass etc. A box of ten will last me at least a couple of years and it is in constant use on every imagineable material.

These tools have come a long way in the last few years since I started to use them, you only have to look at Rich's ones, they are great, all filtering out from mainstream engineering. It is just a shame that they can't be rotated and resharpened like these old versions can be.

The main reason I use this type is because when you have rotated the tip say a dozen or so times and it is then blunt all the way around, but not damaged, I swipe the top surface over a diamond lap, and they are then reusable on materials that require zero top rake, brass etc. A box of ten will last me at least a couple of years and it is in constant use on every imagineable material.

These tools have come a long way in the last few years since I started to use them, you only have to look at Rich's ones, they are great, all filtering out from mainstream engineering. It is just a shame that they can't be rotated and resharpened like these old versions can be.

- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

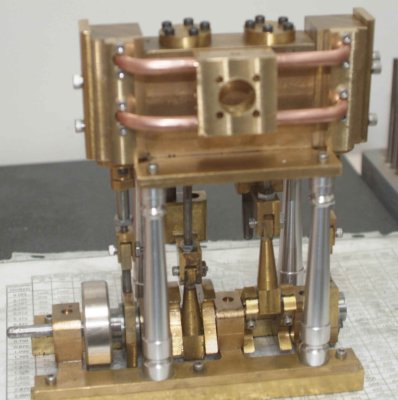

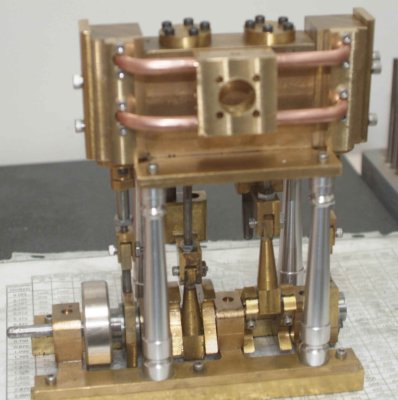

For CNC the round insert is useful as it can cut on both sides of a feature as opposed to needing both a LH and RH tool. The columns on this build were turned using a round insert:

Similar threads

- Replies

- 0

- Views

- 398

- Replies

- 1

- Views

- 562

- Replies

- 2

- Views

- 756

- Replies

- 0

- Views

- 402