BobWarfield

Well-Known Member

- Joined

- Dec 27, 2007

- Messages

- 1,151

- Reaction score

- 1

My latest Harbor Freight flyer shows their butterfly impact wrenches are once again on sale. They're $14.99, regular $29.99.

Why would you care?

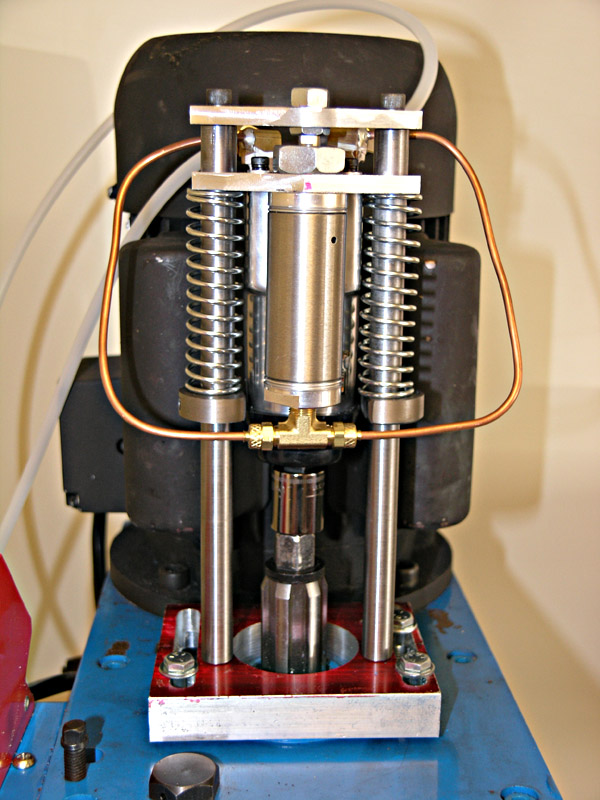

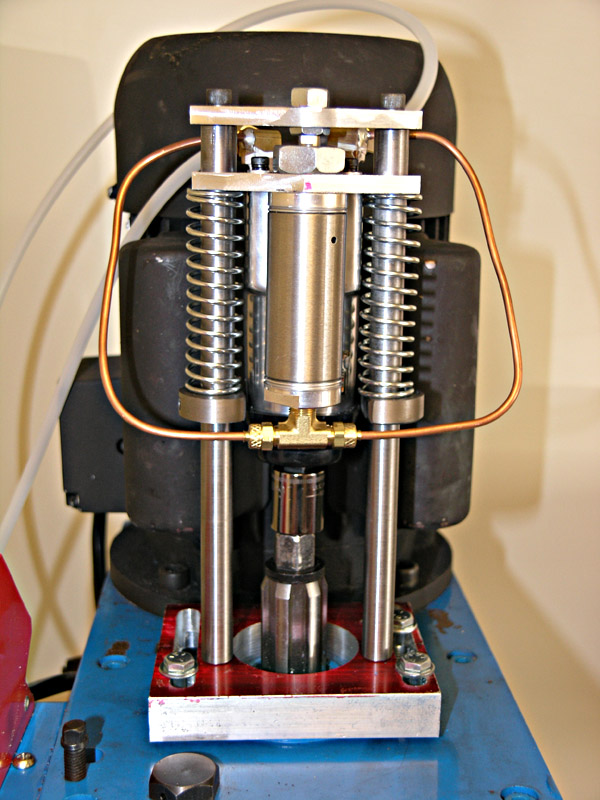

I built a really neat powered drawbar from one for my mill:

That and a power feed can really improve your mill productivity.

But here's another tip: you can use the butterfly impact wrench without building the drawbar too!

Here's what I mean by a butterfly impact wrench:

It's a little fist-sized bundle of goodness for drawbars. Snap the right socket on it and you can reach up and zzzzzzzzzzzzzzzzzzzziiippppp, DONE!

A air ratchet works too, but there's a reason the drawbar wrenches have a little hammer as well as a socket, and the impact wrench is 2 in 1.

Try it, you'll like it! And when you get around to it, build the power drawbar too!

Best,

BW

Why would you care?

I built a really neat powered drawbar from one for my mill:

That and a power feed can really improve your mill productivity.

But here's another tip: you can use the butterfly impact wrench without building the drawbar too!

Here's what I mean by a butterfly impact wrench:

It's a little fist-sized bundle of goodness for drawbars. Snap the right socket on it and you can reach up and zzzzzzzzzzzzzzzzzzzziiippppp, DONE!

A air ratchet works too, but there's a reason the drawbar wrenches have a little hammer as well as a socket, and the impact wrench is 2 in 1.

Try it, you'll like it! And when you get around to it, build the power drawbar too!

Best,

BW