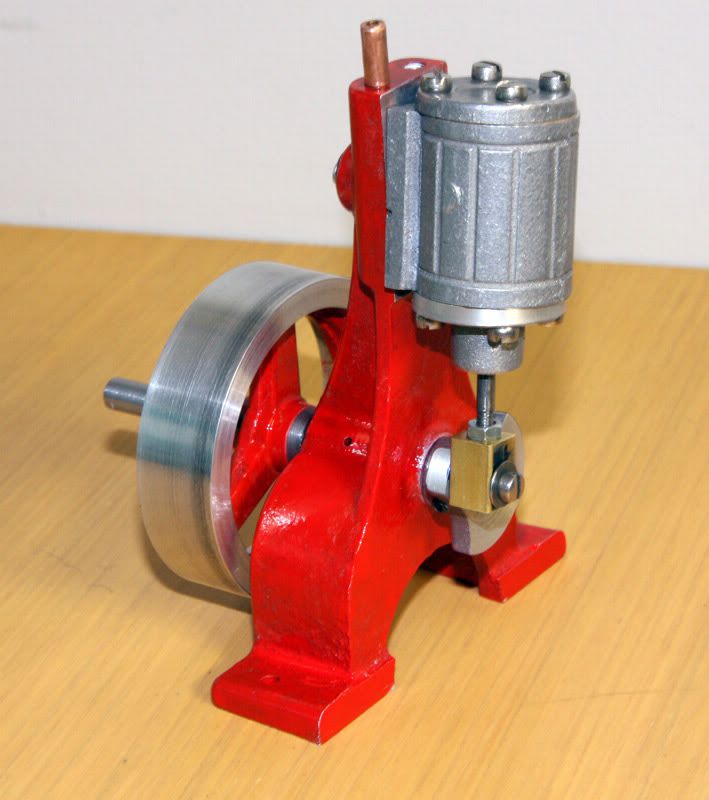

Dear All

This is my first attempt at making an engine from castings and only my second steam engine. It runs (just) with me blowing into it and easily on a little compressor.

I modified the kit a little as it is imperial and all my taps etc are metric. I didn't take any WIP images. I must start doing that.

I'm quite pleased with it considering I'm very new at using a mill and lathe.

I just need to mount it on a base. Not sure whether I should paint the cylinder or leave it bare.

This is my first attempt at making an engine from castings and only my second steam engine. It runs (just) with me blowing into it and easily on a little compressor.

I modified the kit a little as it is imperial and all my taps etc are metric. I didn't take any WIP images. I must start doing that.

I'm quite pleased with it considering I'm very new at using a mill and lathe.

I just need to mount it on a base. Not sure whether I should paint the cylinder or leave it bare.