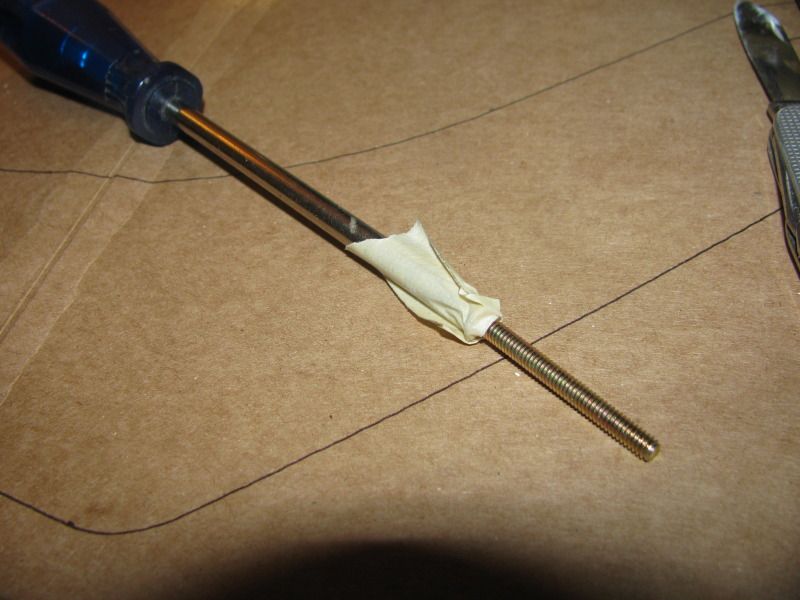

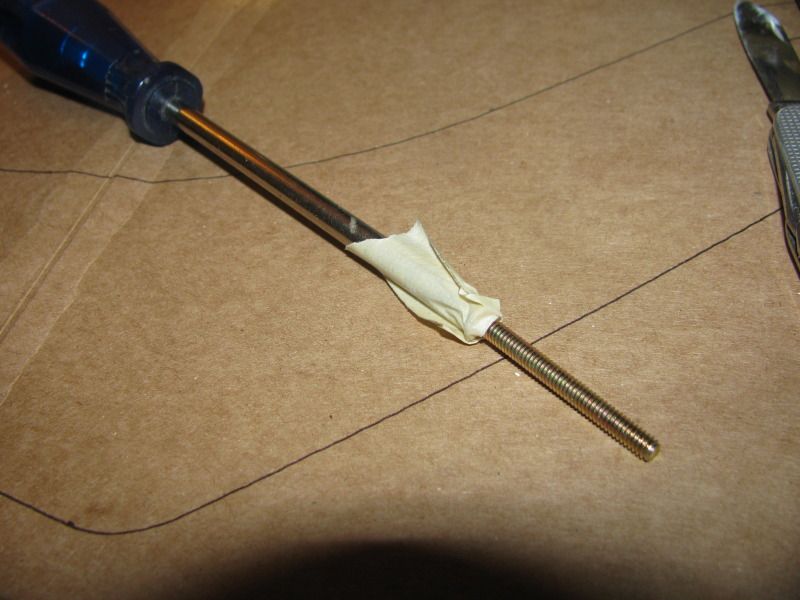

Well, for me anyways. I was putting up new light fixtures on the ceiling this morning in the never ending renovation of our bungalow. The screws supplied had a very shallow Phillips head in them, and ther was just no way they would stay on the end of the screwdriver while I perched on a stepladder and reached over my head trying to screw them through a new light support and into the octagon electrical box. After dropping the screw half a dozen times, I went and got some masking tape out of my engineering office, poked a hole in the center of a 2" long piece and shoved the screw through from the sticky side. Then I stuck the tape to the shank of the screwdriver. Problem solved!!! When the screw was tightened in place, there was ejnough adhesion between the tape and the screwdriver that the screw stayed in place and the tape all came away with the screwdriver. I just can't figure out why its taken me damn near 66 years to figure this out!!! I guess that living in Canada, and most of our screws being Robertson heads, Ijust never ran into that problem before.