Hi

I need a tubing bender for the exhaust, fuel, and coolant pipes on the Snow tandem that I'm building, so I got busy and made one according to the plans drawn up by George Britnell.

Started by turning some drill rod to the diameter of the tube, (four times, as I've got four different sizes of tubing to deal with) then used a ball turning device to form the radius on the end of the pieces, then to the mill to remove half of the material

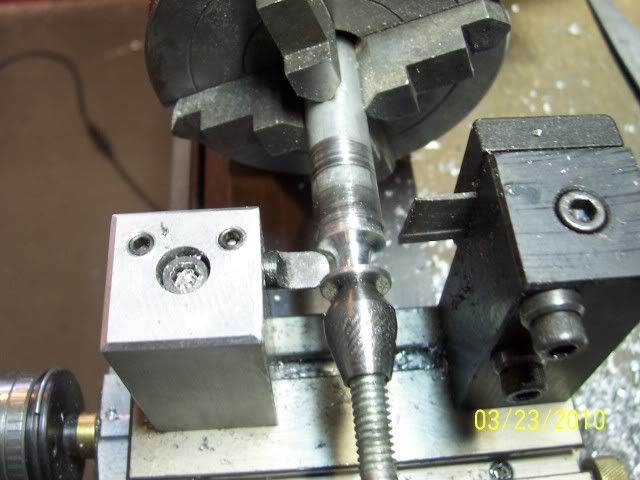

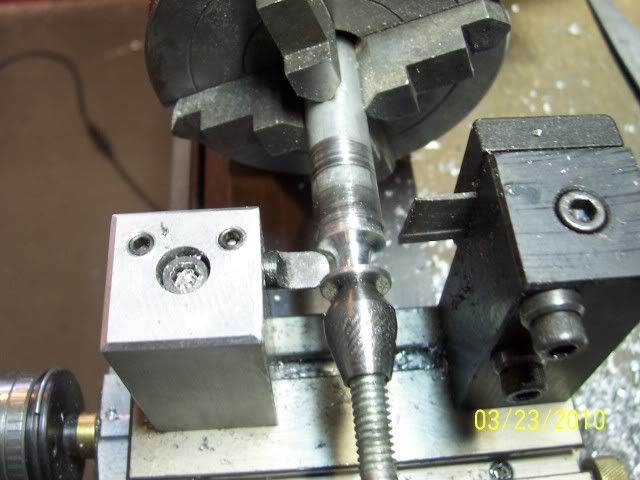

hardened, and a lick on the grinder, and then into a purpose-built tool holder, and here's one cutting a forming die

Here's all the bits assembled and ready to go

And here's the set of dies, the bender, and a test piece

This thing works a treat, thanks George! Great design work.

No more excuses, will be getting back to the Snow now....

Cheers, Joe

I need a tubing bender for the exhaust, fuel, and coolant pipes on the Snow tandem that I'm building, so I got busy and made one according to the plans drawn up by George Britnell.

Started by turning some drill rod to the diameter of the tube, (four times, as I've got four different sizes of tubing to deal with) then used a ball turning device to form the radius on the end of the pieces, then to the mill to remove half of the material

hardened, and a lick on the grinder, and then into a purpose-built tool holder, and here's one cutting a forming die

Here's all the bits assembled and ready to go

And here's the set of dies, the bender, and a test piece

This thing works a treat, thanks George! Great design work.

No more excuses, will be getting back to the Snow now....

Cheers, Joe