DickDastardly40

Well-Known Member

- Joined

- Oct 23, 2007

- Messages

- 309

- Reaction score

- 0

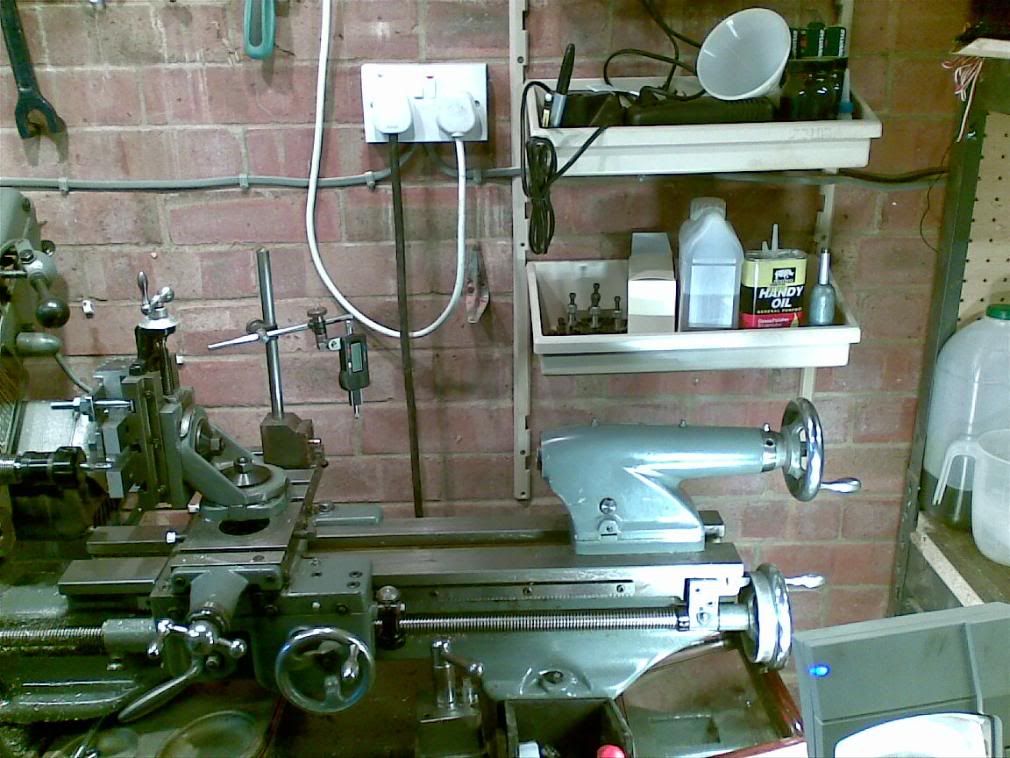

Once I'd struck floor the rest was 'easy', here is my Garage after tidying and spruced specially for you, my guests; Welcome.

It measures about 6m x 2.6m (19'6" X 8'6") and has a roller shutter door at one end and a door to the utility room and downstairs loo at the other.

My machinery is a Myford Super 7B with imperial box, a BCA Sigma Allen Jig borer, a chinese drill press, a combination wet/dry grinder, and a 2.5HP compressor which gives 9.5 CFM output

Storage comprises some substantial racking won from work and a roll around toolbox and some p;astic drawer units which work well. The benches were kindly left by the previous occupant of the house.

In case of a 4 pic limit per post I'll continue on another pane

It measures about 6m x 2.6m (19'6" X 8'6") and has a roller shutter door at one end and a door to the utility room and downstairs loo at the other.

My machinery is a Myford Super 7B with imperial box, a BCA Sigma Allen Jig borer, a chinese drill press, a combination wet/dry grinder, and a 2.5HP compressor which gives 9.5 CFM output

Storage comprises some substantial racking won from work and a roll around toolbox and some p;astic drawer units which work well. The benches were kindly left by the previous occupant of the house.

In case of a 4 pic limit per post I'll continue on another pane