vlmarshall

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 1,138

- Reaction score

- 1

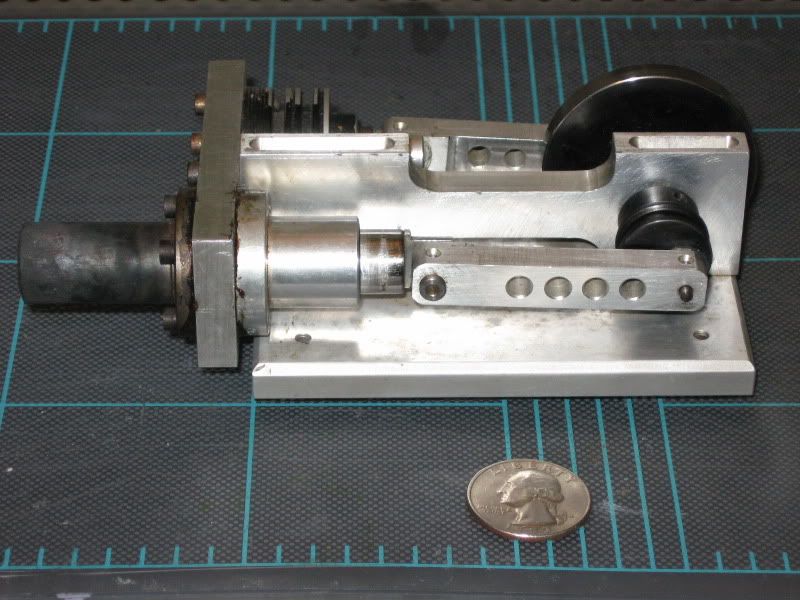

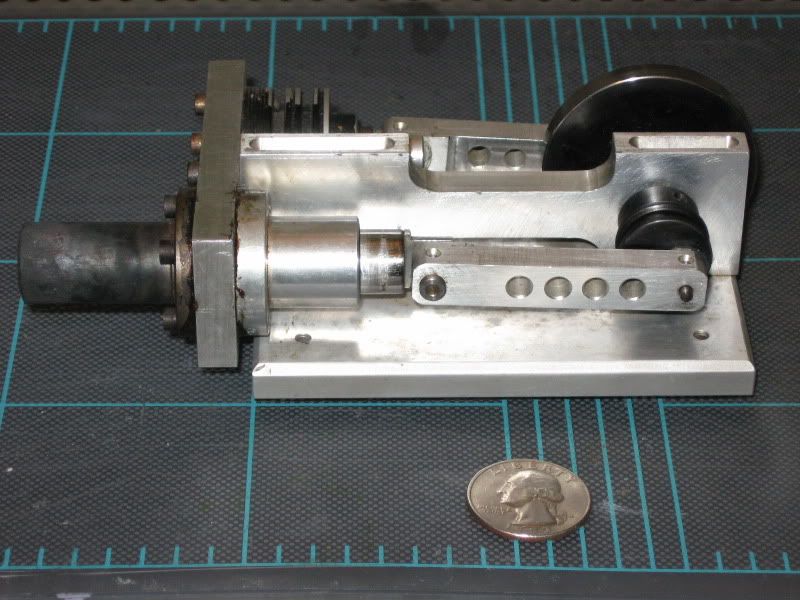

I guess I'll post a bit about the first engine I built, about 12 years ago, a Stirling hot-air engine. This is my only remaining Stirling, one of them being destroyed, another lost, and the fourth was never finished.

This engine is based on Koichi Hirata's "LSE-01" engine, available here: http://www.bekkoame.ne.jp/~khirata/english/make.htm

I decided to build the engine as a horizontal, instead of the top-heavy vertical design in the plan.

While preparing to build this, I couldn't find the glass syringes the plans suggested using for the pistons and cylinders.

Instead, I made these parts from tool steel, heat-treating them all, and fitting the cylinders to the pistons on the Sunnen honing machine at work. The cylinder sleeves are pressed into aluminum mounting flanges, the working piston also includes fins, a glassbeaded texture, and a thin (now peeling) coating of flat-black paint, to help dispel heat.

The bore is increased to 13mm, but I left the stroke at the planned 8mm.

The crank runs on ball bearings, and both the flywheel and the displacer piston's crank throw are only secured with pairs of setscrews, so I could experiment with timing differences or change the running direction.

During my experimenting with this engine, I rolled up a bit of brass screen and pushed it into the transfer port between cylinders. That little bit of brass greatly increased the efficiency of the engine, increasing the run-on time after heat is removed. The brass pulls heat from the air that flows into the working cylinder, and after the air has cooled, gives back a bit of it's stored heat, 'preheating' the air just a little.

The hot cylinder cap is stainless steel, although you can't tell anymore. ;D

All of the material for this engine was picked out of the scrap bin.

12 years of shelves, demos, and experiments have left this thing looking a bit scruffy.

Thanks for looking.

-Vernon

This engine is based on Koichi Hirata's "LSE-01" engine, available here: http://www.bekkoame.ne.jp/~khirata/english/make.htm

I decided to build the engine as a horizontal, instead of the top-heavy vertical design in the plan.

While preparing to build this, I couldn't find the glass syringes the plans suggested using for the pistons and cylinders.

Instead, I made these parts from tool steel, heat-treating them all, and fitting the cylinders to the pistons on the Sunnen honing machine at work. The cylinder sleeves are pressed into aluminum mounting flanges, the working piston also includes fins, a glassbeaded texture, and a thin (now peeling) coating of flat-black paint, to help dispel heat.

The bore is increased to 13mm, but I left the stroke at the planned 8mm.

The crank runs on ball bearings, and both the flywheel and the displacer piston's crank throw are only secured with pairs of setscrews, so I could experiment with timing differences or change the running direction.

During my experimenting with this engine, I rolled up a bit of brass screen and pushed it into the transfer port between cylinders. That little bit of brass greatly increased the efficiency of the engine, increasing the run-on time after heat is removed. The brass pulls heat from the air that flows into the working cylinder, and after the air has cooled, gives back a bit of it's stored heat, 'preheating' the air just a little.

The hot cylinder cap is stainless steel, although you can't tell anymore. ;D

All of the material for this engine was picked out of the scrap bin.

12 years of shelves, demos, and experiments have left this thing looking a bit scruffy.

Thanks for looking.

-Vernon