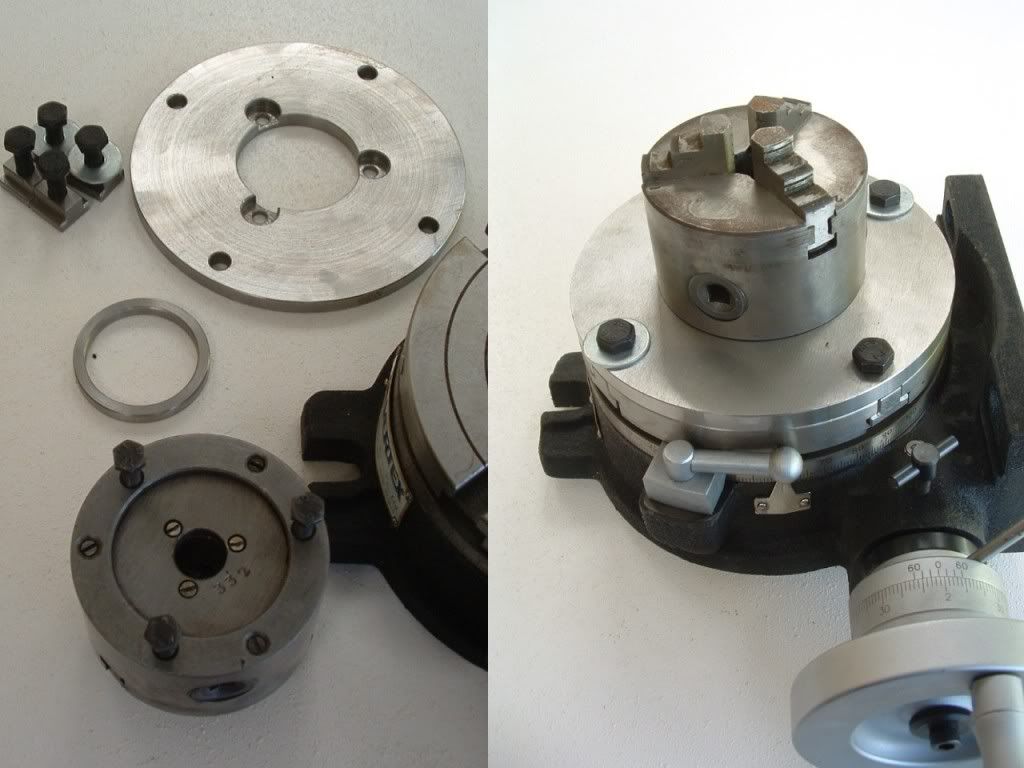

I have a little problem, I want to mount a 4 jaw chuck to my vertex HV4 rotary table

But the problem is my rotary table only has 3 t slots, and a 4 jaw chuck has 4 mounting holes. has anyone found a a way of doing this?

Obviously i could buy another rotary table with 4 t slots, but the rotary table i have cost a fair bit.

Plus it is so much better than the Soba table i originally had but took it back to the shop, the soba one was so bad i'm put off buying anything made by soba.

My rotary table has a 2mt centre.

But the problem is my rotary table only has 3 t slots, and a 4 jaw chuck has 4 mounting holes. has anyone found a a way of doing this?

Obviously i could buy another rotary table with 4 t slots, but the rotary table i have cost a fair bit.

Plus it is so much better than the Soba table i originally had but took it back to the shop, the soba one was so bad i'm put off buying anything made by soba.

My rotary table has a 2mt centre.