- Joined

- Jan 30, 2011

- Messages

- 365

- Reaction score

- 72

Hi,

On another thread one of our esteemed moderators noticed I had a series of holes around my lathe chuck commenting that perhaps I found them useful.

Obviously used for dividing they certainly are that but having been there for so long they are never given second thought to.

Perhaps though they may now be of interest to someone....

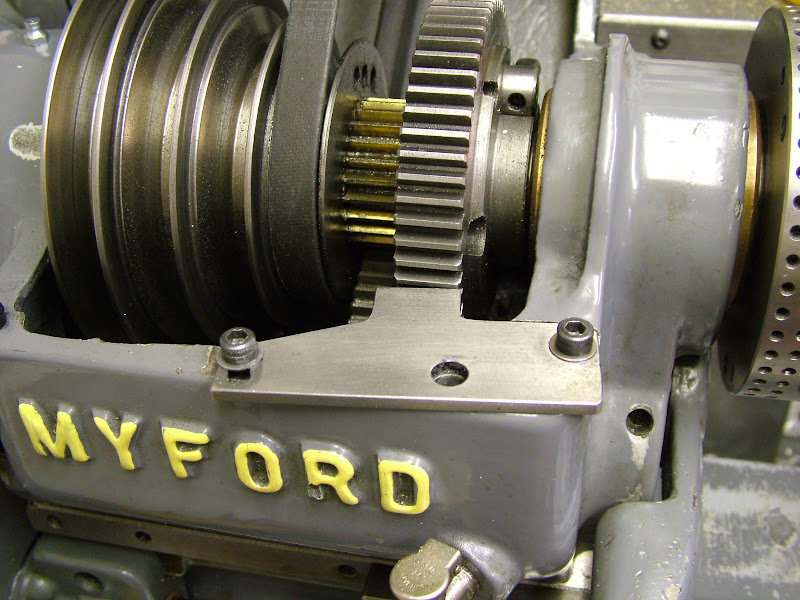

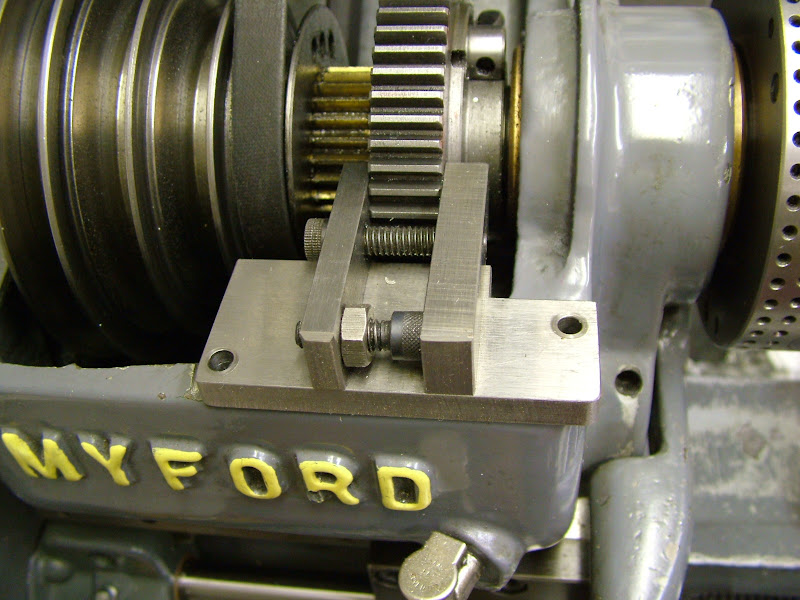

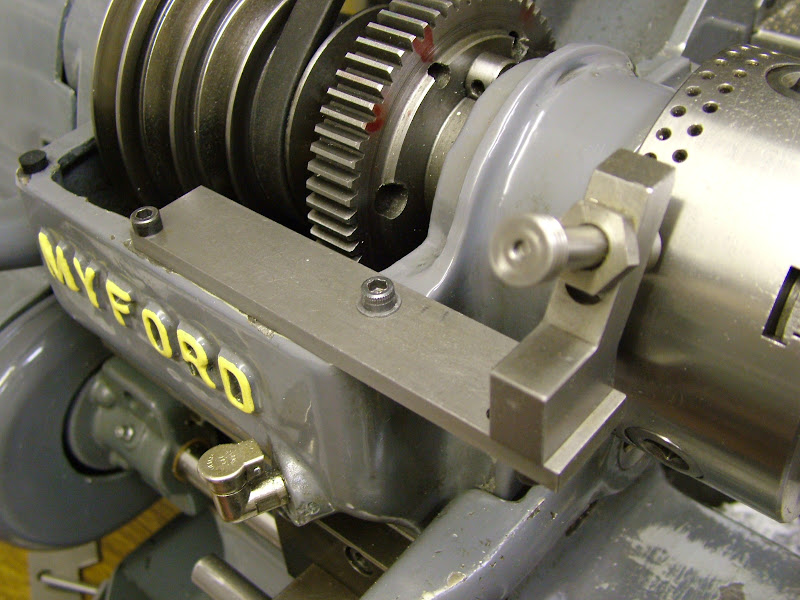

First came the ubiquitous bullwheel dividing device. This was my interpretation, trying to make it as basic as possible. It did need a rather elaborate set up of a crosslide drilling/milling attachment hung off to one side from a vertical slide to mill the platform away but by taking it very steadily the result was worth it. (The large hole is where the rubber buffer was fitted - it was then fitted to the plate - which remains permanently in place - but soon came loose. The remaining one appears more than adequate)

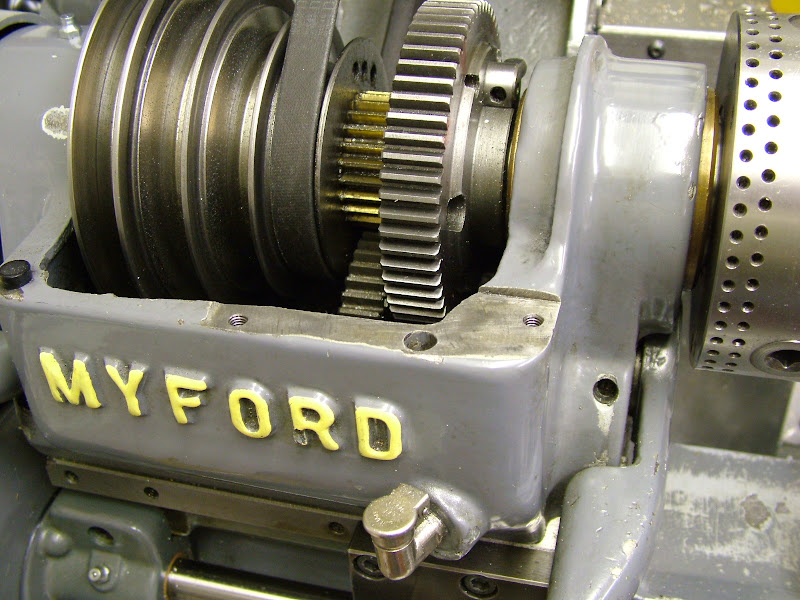

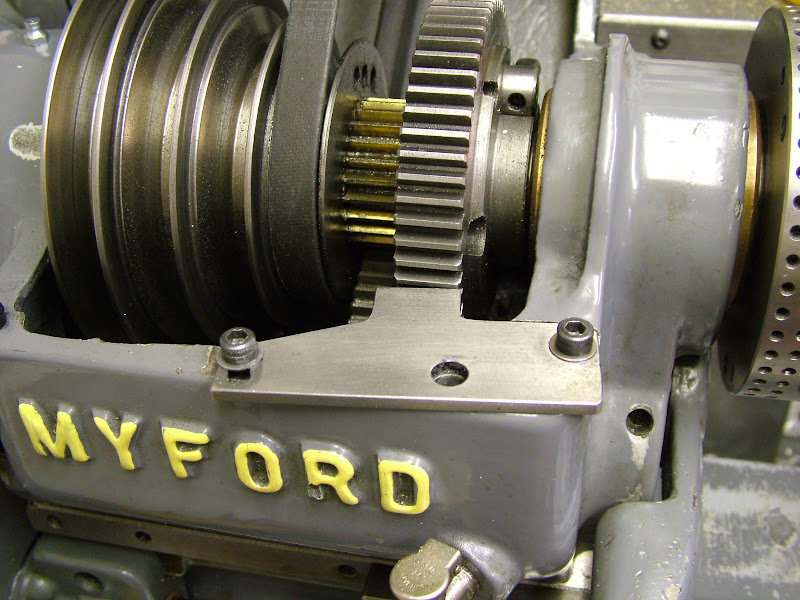

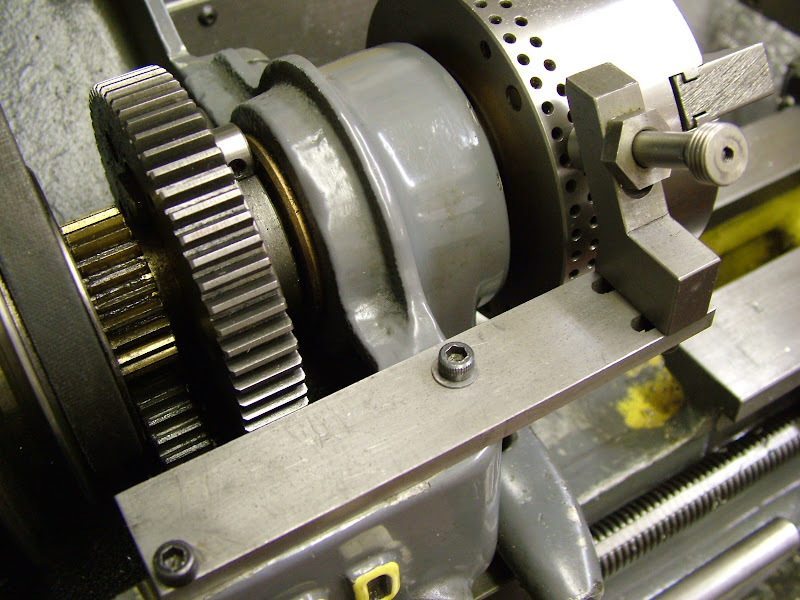

The limitation of course is the 60 teeth and at the time (1981) I was retraining as a milling machinist with access to some lovely kit including of course a dividing head hence the 48 and 50 hole divisons ;D

The bracket once bolted is fixed but the detent arm is moveable to align with either row

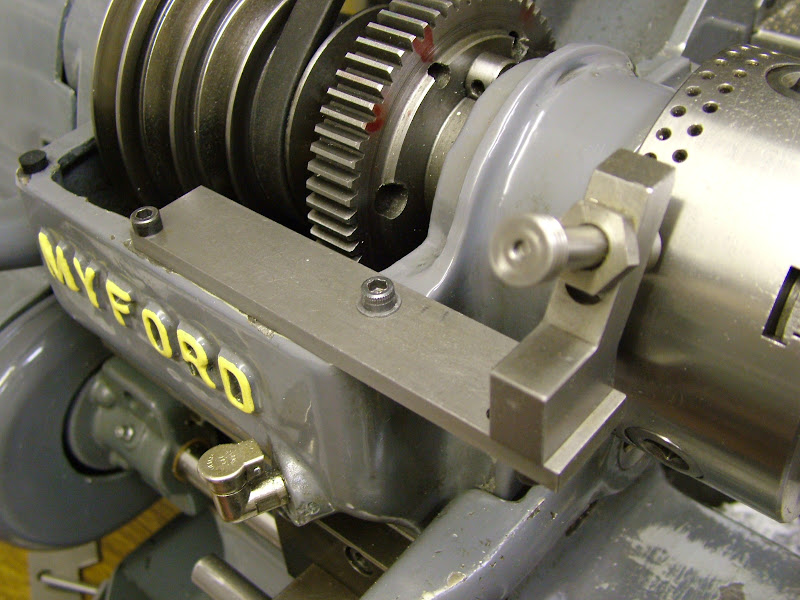

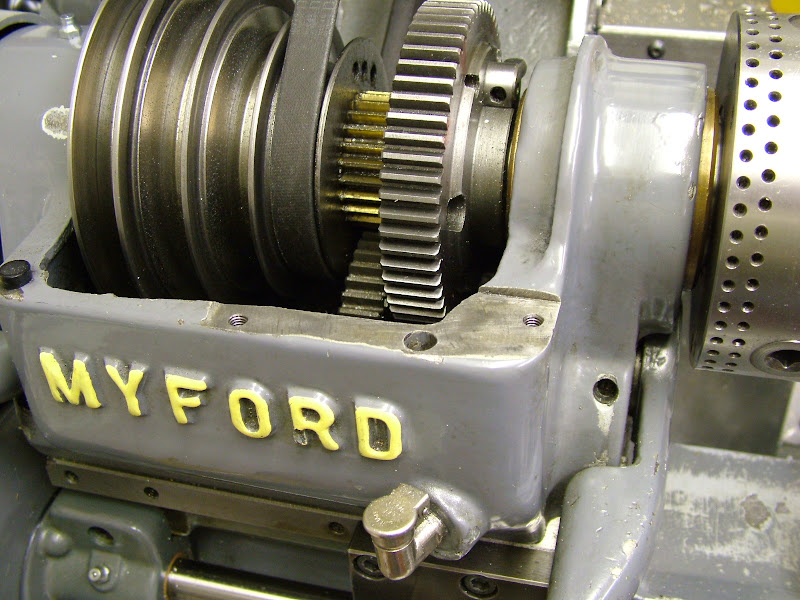

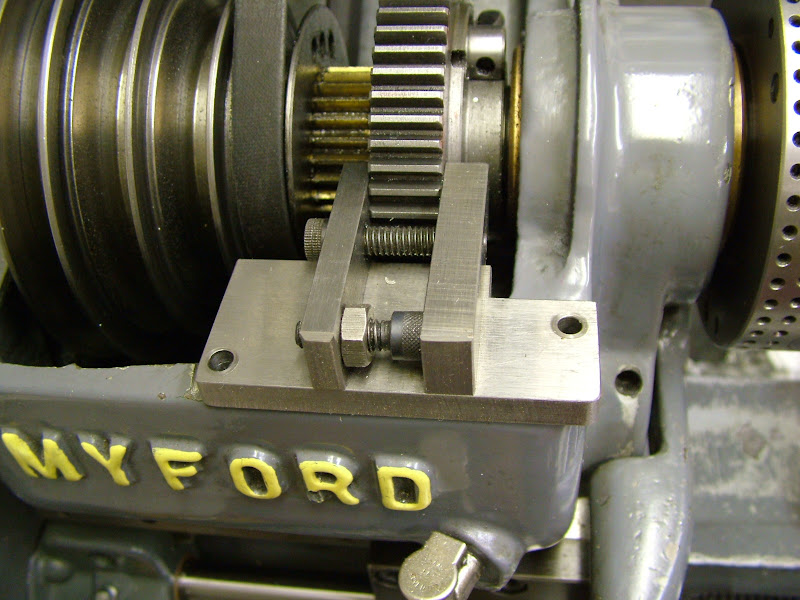

Much later when working on a Bentley BR2 (still as yet unfinished :-[) the need for multiples of 9 and 7 were required and these were dealt with by making a division plate that loctated in the rear of the spindle with the detent bolted to the gear banjo. Some of the work really warranted having the spindle locked so that 'platform' came in handy once again

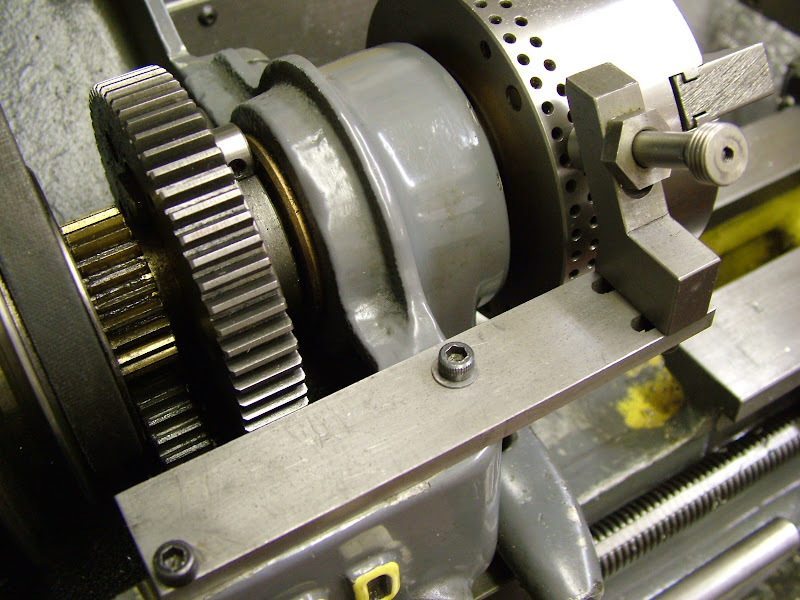

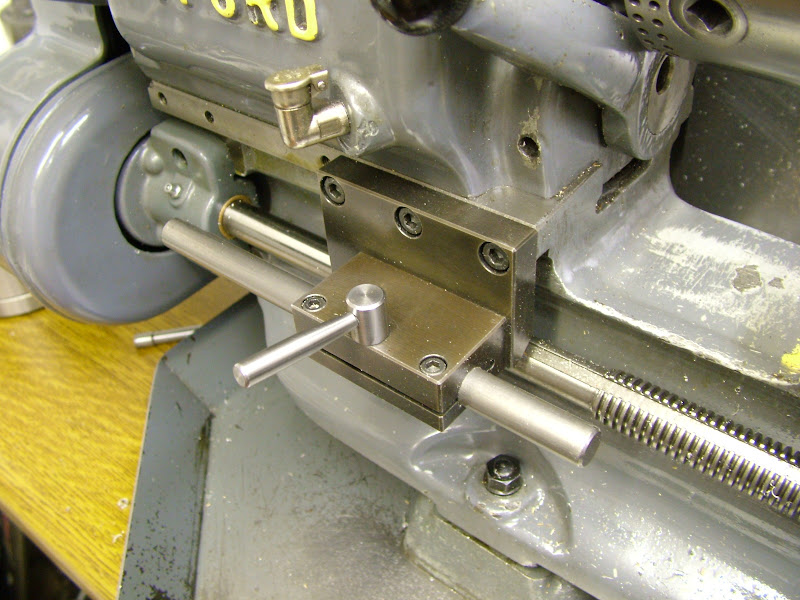

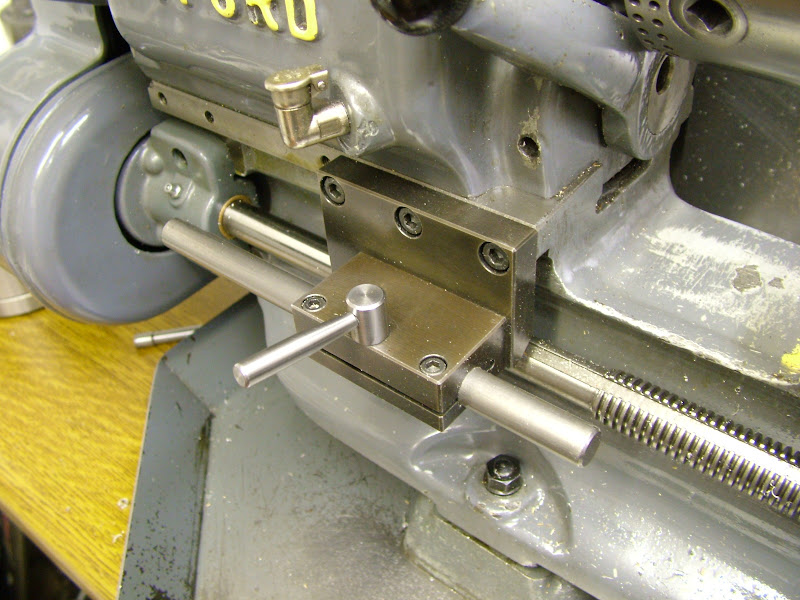

Finally, while we are the subject of small mods this little fellow has to be the most useful of all. It's just a basic bed stop but one that is in constant use - simply couldn't be without it

Hope that is of interest to someone - not least our 'Steamer'

Regards - Ramon

On another thread one of our esteemed moderators noticed I had a series of holes around my lathe chuck commenting that perhaps I found them useful.

Obviously used for dividing they certainly are that but having been there for so long they are never given second thought to.

Perhaps though they may now be of interest to someone....

First came the ubiquitous bullwheel dividing device. This was my interpretation, trying to make it as basic as possible. It did need a rather elaborate set up of a crosslide drilling/milling attachment hung off to one side from a vertical slide to mill the platform away but by taking it very steadily the result was worth it. (The large hole is where the rubber buffer was fitted - it was then fitted to the plate - which remains permanently in place - but soon came loose. The remaining one appears more than adequate)

The limitation of course is the 60 teeth and at the time (1981) I was retraining as a milling machinist with access to some lovely kit including of course a dividing head hence the 48 and 50 hole divisons ;D

The bracket once bolted is fixed but the detent arm is moveable to align with either row

Much later when working on a Bentley BR2 (still as yet unfinished :-[) the need for multiples of 9 and 7 were required and these were dealt with by making a division plate that loctated in the rear of the spindle with the detent bolted to the gear banjo. Some of the work really warranted having the spindle locked so that 'platform' came in handy once again

Finally, while we are the subject of small mods this little fellow has to be the most useful of all. It's just a basic bed stop but one that is in constant use - simply couldn't be without it

Hope that is of interest to someone - not least our 'Steamer'

Regards - Ramon