G'day folks

i've been getting used to my mini lathe and am now quite impressed with it

i'm makeing a small cam for a stirling plan i have here out of 2041 T? Alu

alloy ( 20% titainium ) and as usual the carbide tipped tools have issues with Titainium

and a small test on 4130 steel ( Chrome Moly) showed the same ( although i was happy the lathe did handle it with a few light passes and did not stall but trying to part off the 20mm bar the carbide was useless as usual)

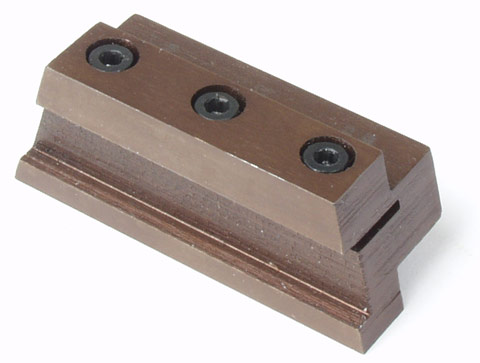

looking for a cutoff tool holder for HSS cutoff toolblades i found nothing! there all too big!

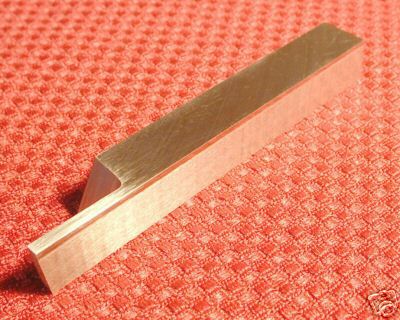

what do you folks use for cut off tools on your mini lathes (C2 size) or am I back to hand making tools outta 3/8" and 1/2" HSS blocks ?

( i have a few )

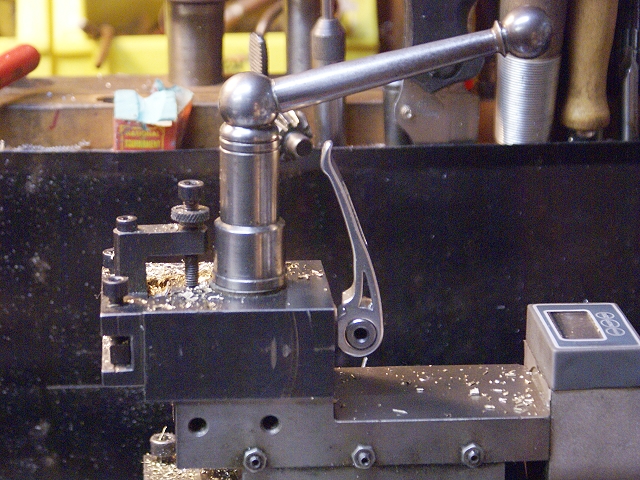

one thing i read was to get a quick change tool post but will this actually fit my mini lathe??

if so what size do i order??

questions questions always with the questions ( more $$ too most likely )

cheers

jack

i've been getting used to my mini lathe and am now quite impressed with it

i'm makeing a small cam for a stirling plan i have here out of 2041 T? Alu

alloy ( 20% titainium ) and as usual the carbide tipped tools have issues with Titainium

and a small test on 4130 steel ( Chrome Moly) showed the same ( although i was happy the lathe did handle it with a few light passes and did not stall but trying to part off the 20mm bar the carbide was useless as usual)

looking for a cutoff tool holder for HSS cutoff toolblades i found nothing! there all too big!

what do you folks use for cut off tools on your mini lathes (C2 size) or am I back to hand making tools outta 3/8" and 1/2" HSS blocks ?

( i have a few )

one thing i read was to get a quick change tool post but will this actually fit my mini lathe??

if so what size do i order??

questions questions always with the questions ( more $$ too most likely )

cheers

jack