Metal Mickey

Well-Known Member

- Joined

- Jul 5, 2008

- Messages

- 612

- Reaction score

- 6

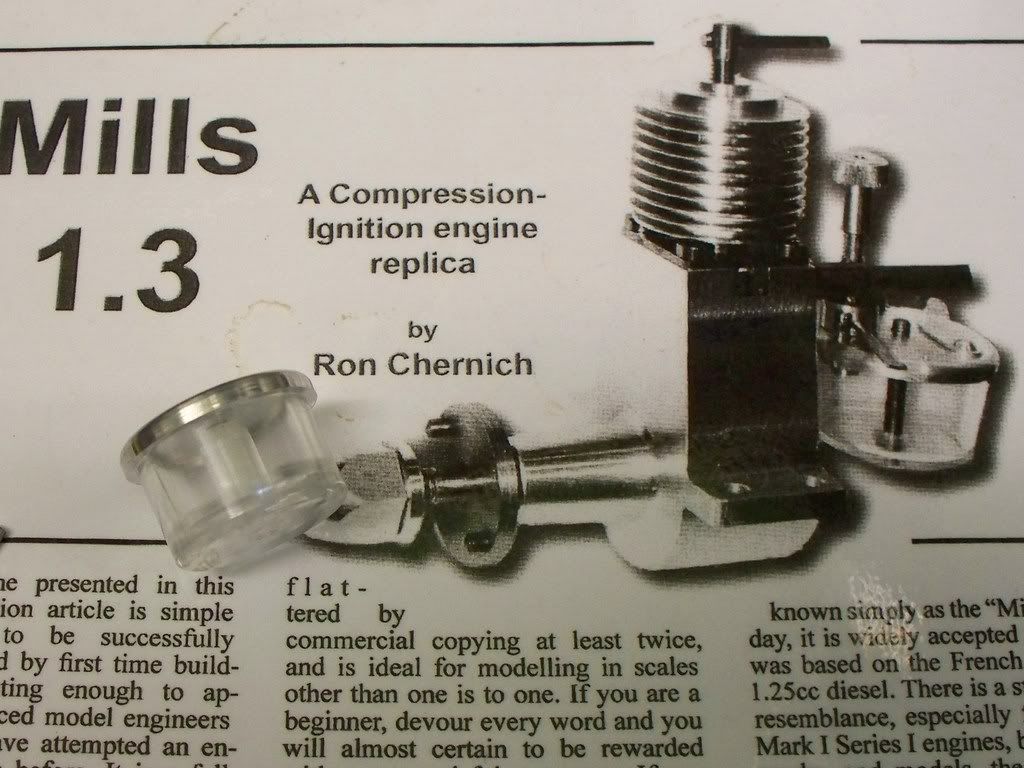

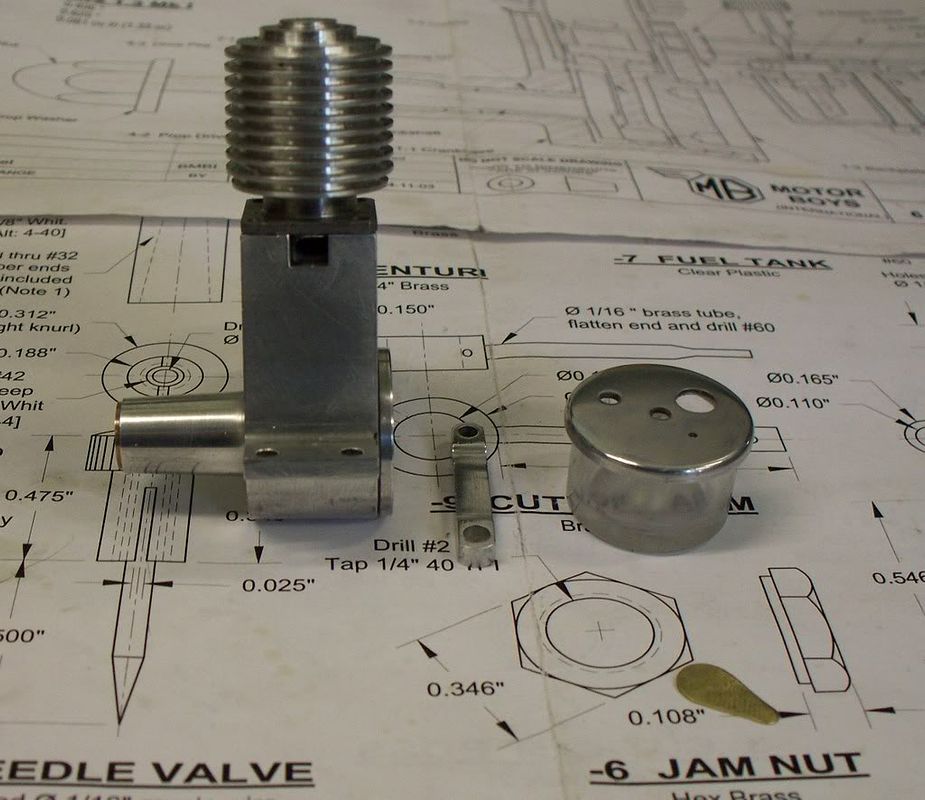

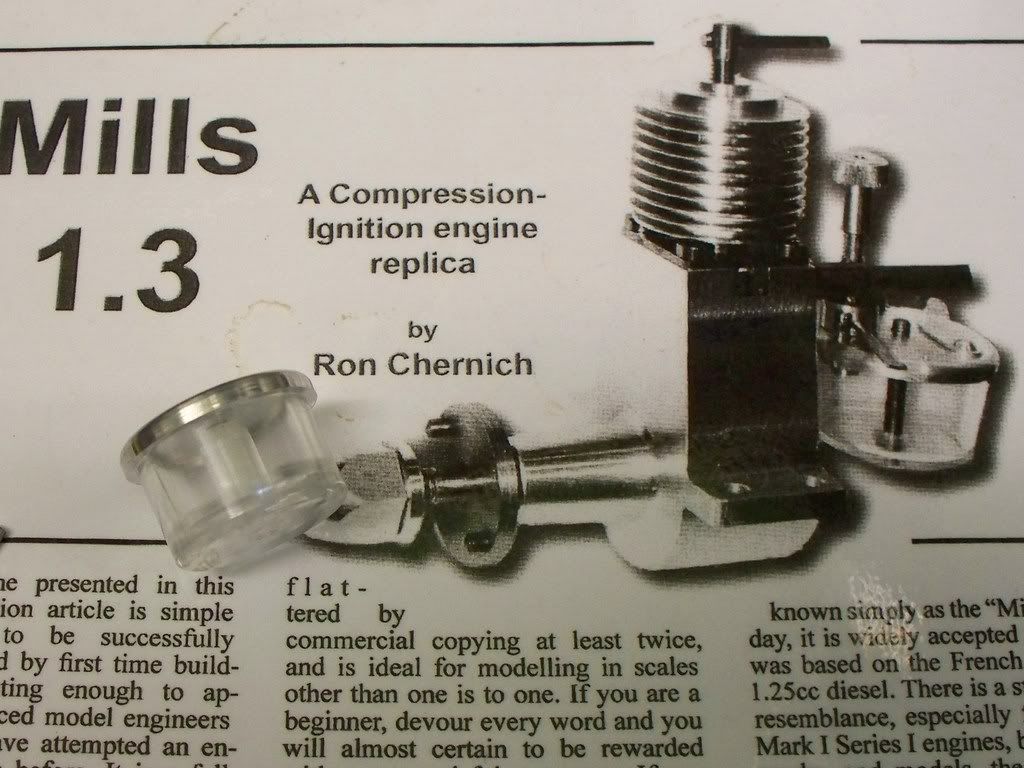

Hello, thought I would share with you the progress of the model diesel engine I am building from the article and plans of Ron Chernich (Australia) he published in issue 1 of Model Engine Builder magazine. I started in January this year. My progress depends on the time I can get in the workshop and how fit I am (excuses I know!) The build is documented on my website (along with all the other projects I have done this year) http://www.mikes-models.com I hope the photo's load as this is my first time.....

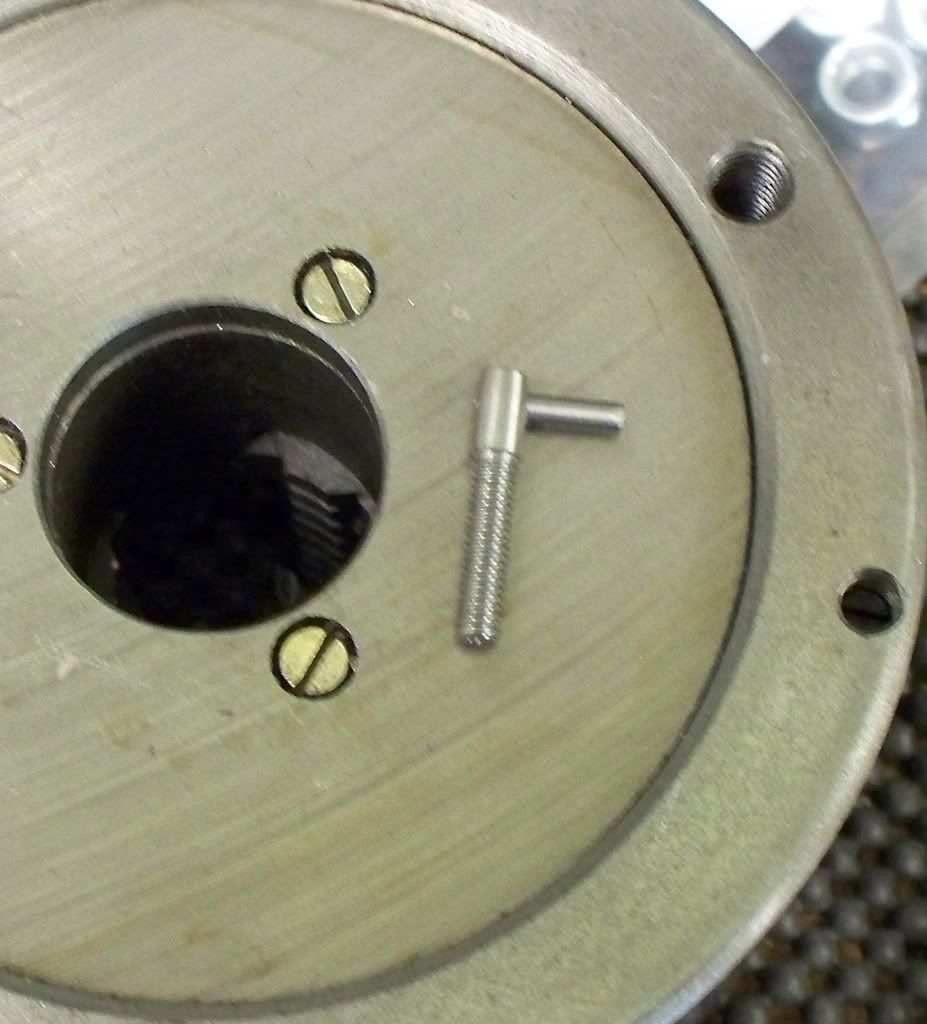

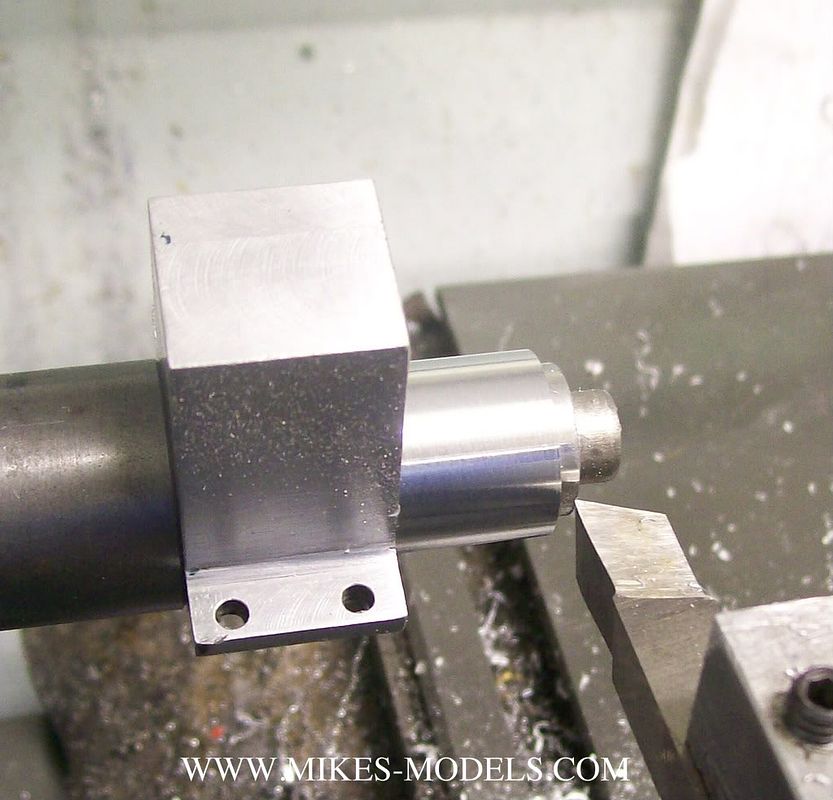

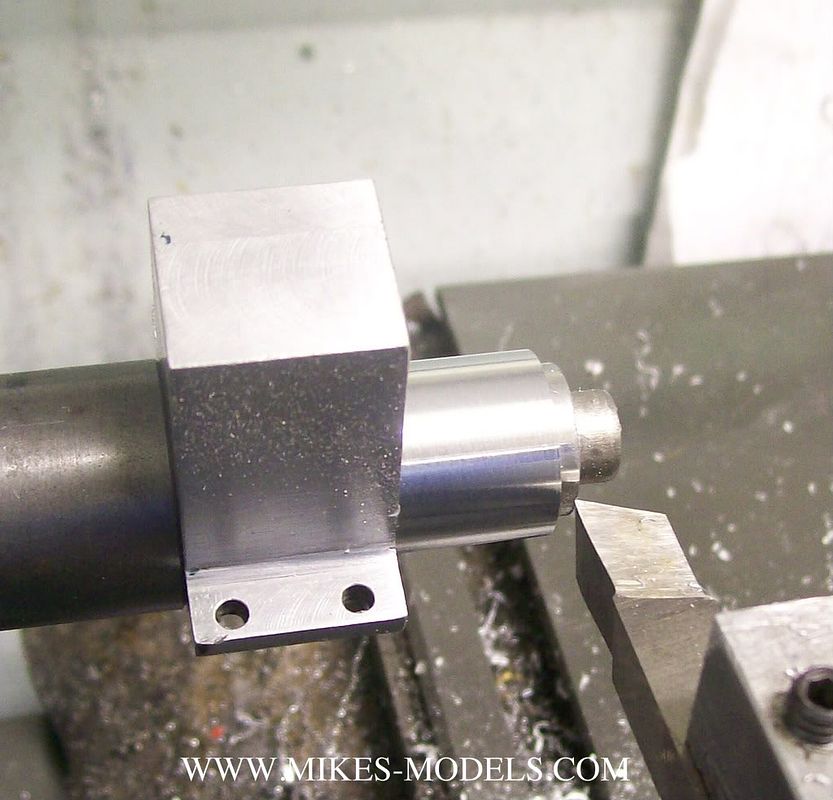

about to start turning the front taper.....

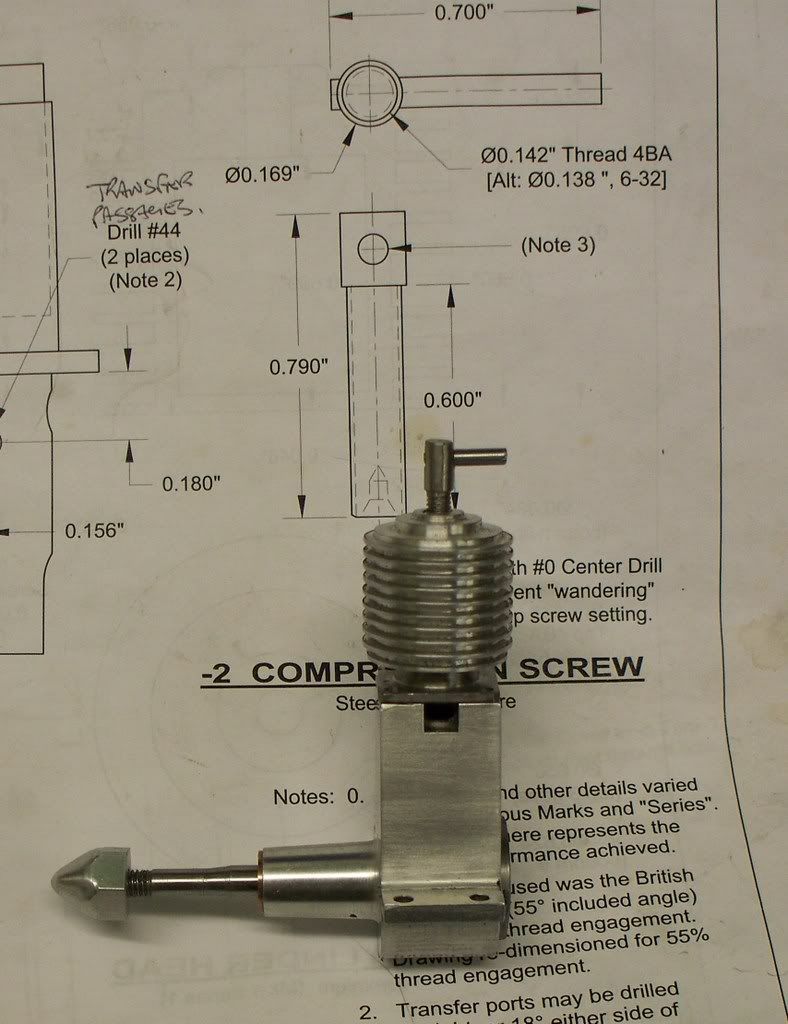

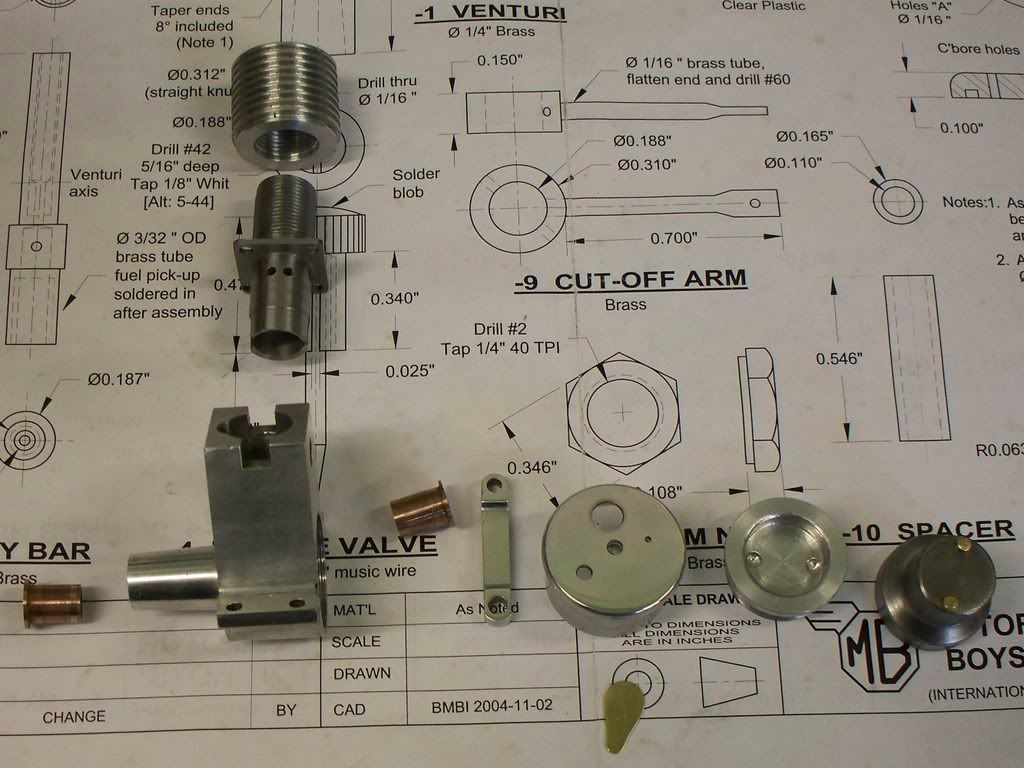

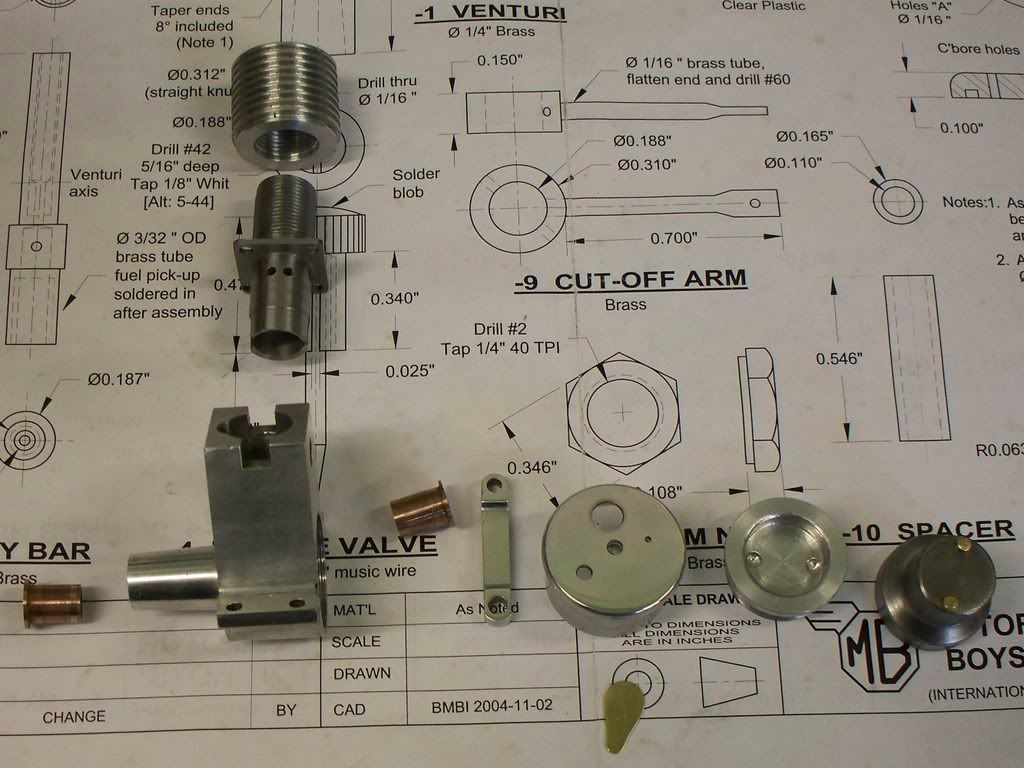

Where I have got to at the moment........

Made 2 fuel tanks and tops. One for a reader of my website and the other for mine.

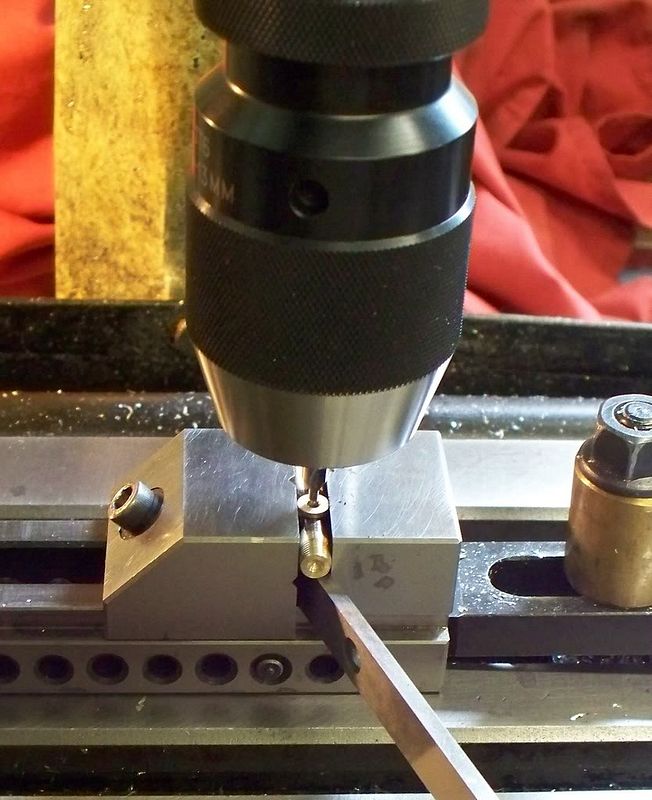

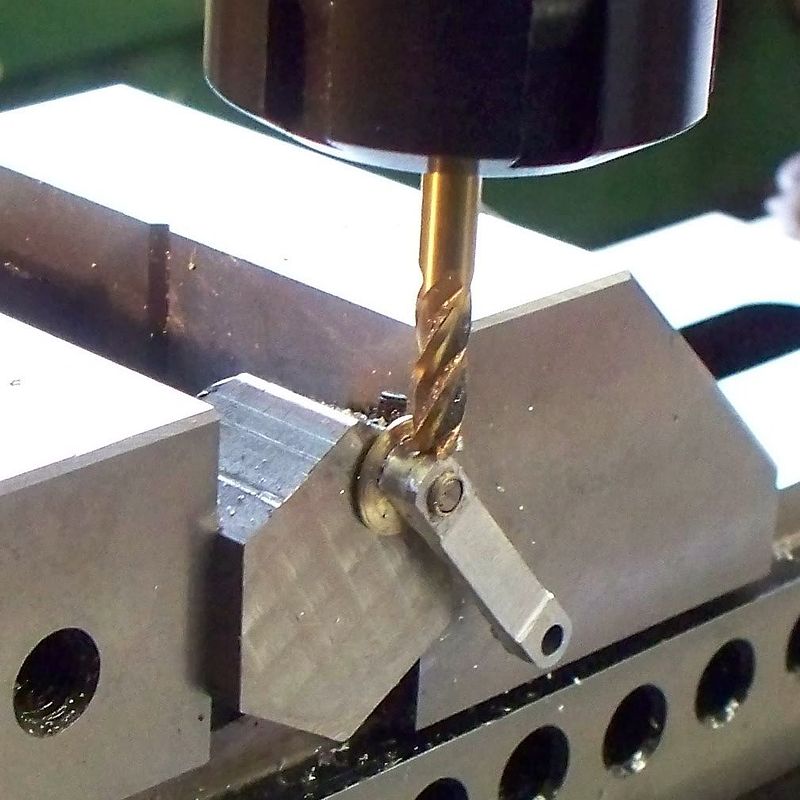

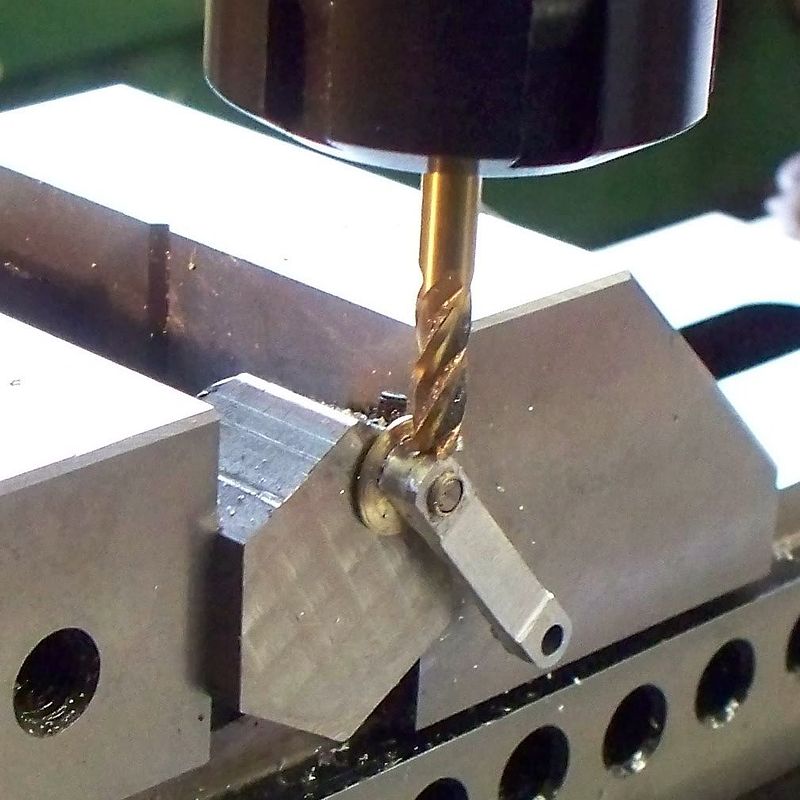

Turning the radius on the end using the method described by Ron Chernich

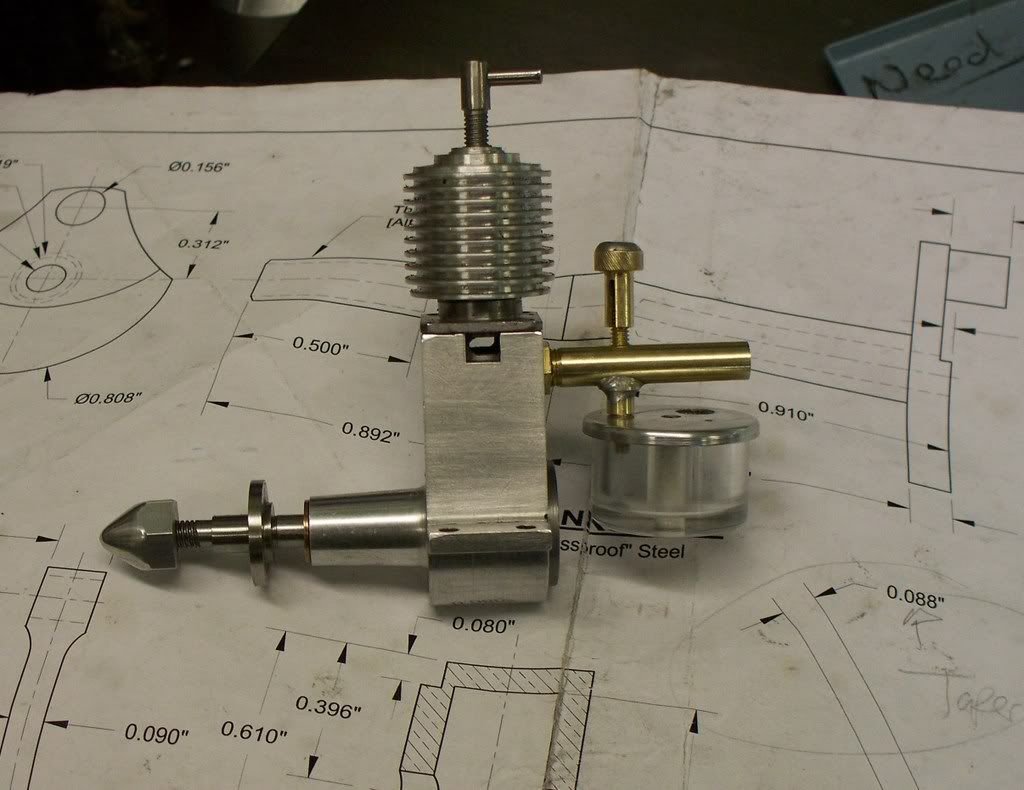

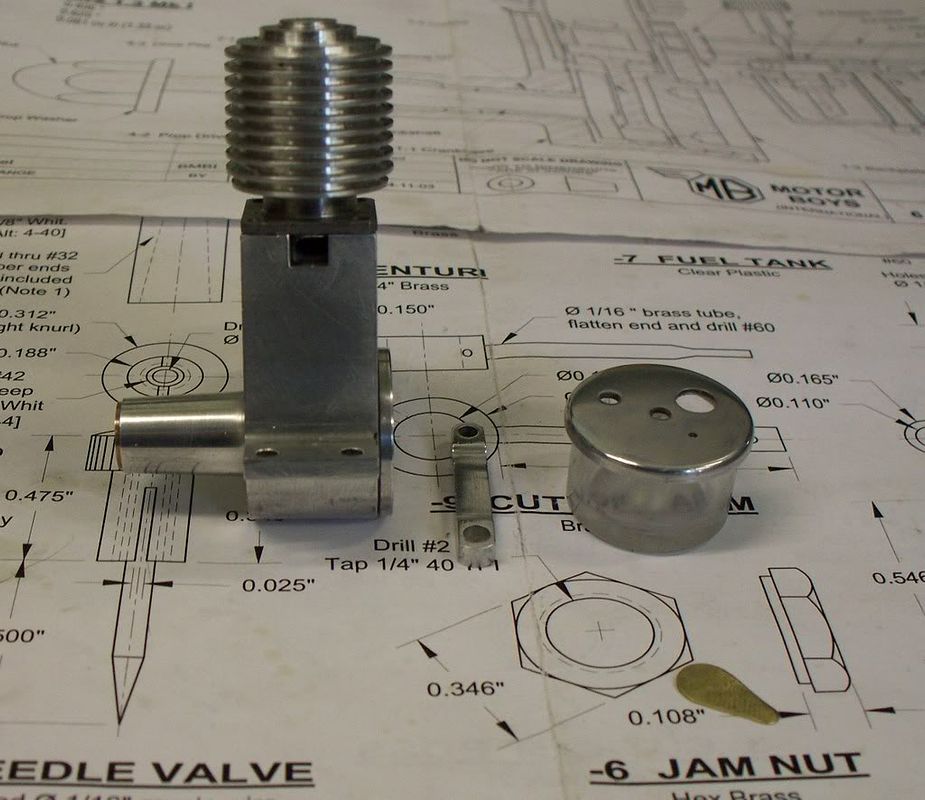

Where I am now and I have jsut started to make the crankshaft.......more to follow......

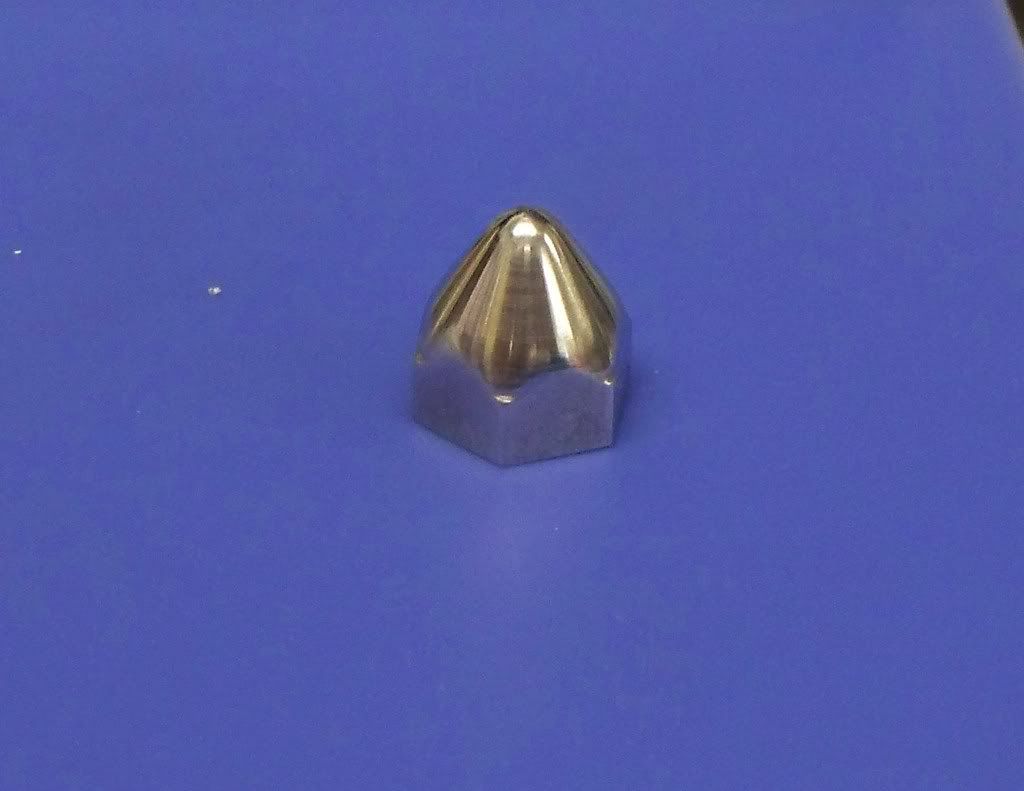

And here they are......getting on with the crankshaft and the prop nut.....

the two phosphur bronze bushes trial fitted to crankshaft blank..

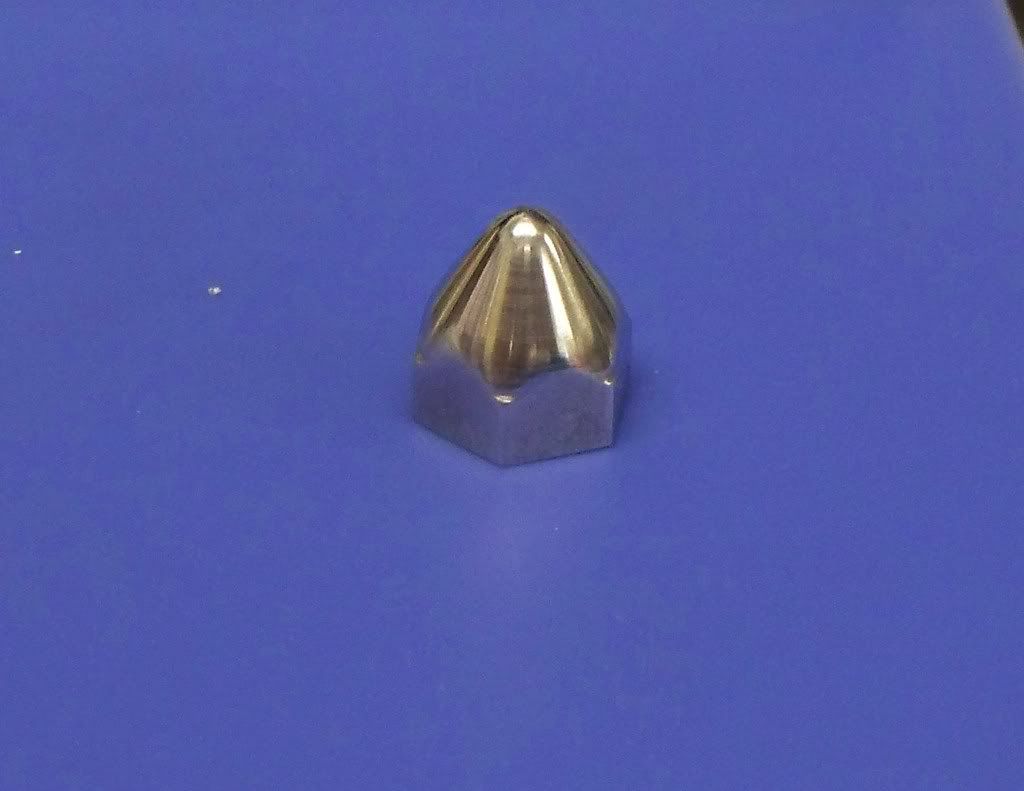

the prop nut....

the prop nut....

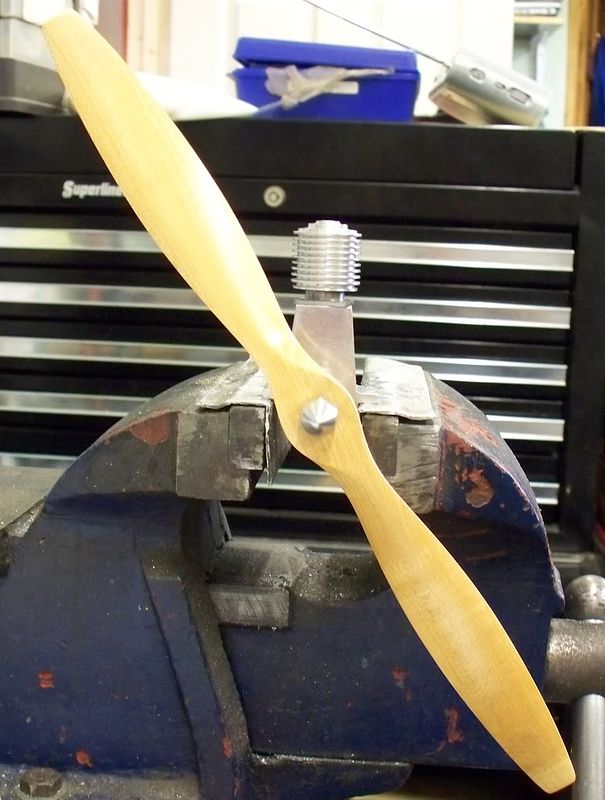

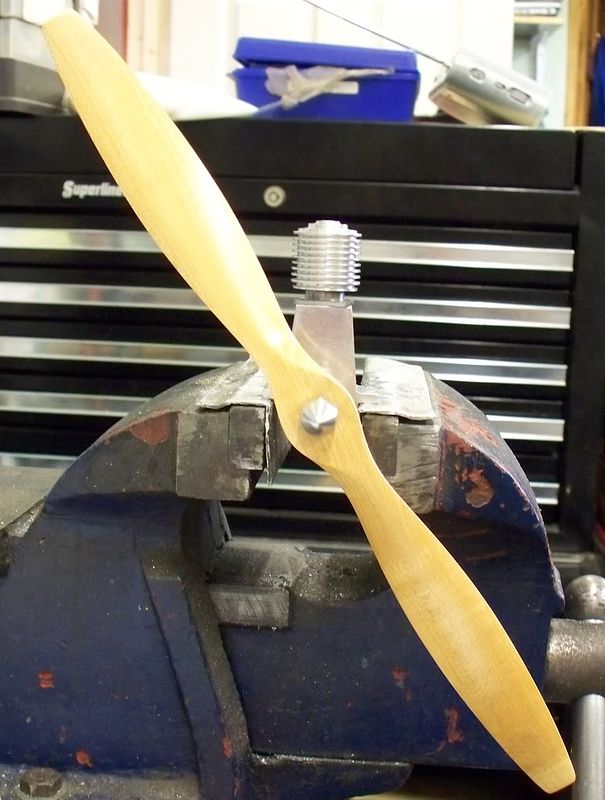

why do we always trial fit to see what its going to look like when finished! (well at least I do......)

why do we always trial fit to see what its going to look like when finished! (well at least I do......)

Ron Chernich, the designer of this engine says it will swing a 12" wooden prop.......well it looks big to me!

about to start turning the front taper.....

Where I have got to at the moment........

Made 2 fuel tanks and tops. One for a reader of my website and the other for mine.

Turning the radius on the end using the method described by Ron Chernich

Where I am now and I have jsut started to make the crankshaft.......more to follow......

And here they are......getting on with the crankshaft and the prop nut.....

the two phosphur bronze bushes trial fitted to crankshaft blank..

Ron Chernich, the designer of this engine says it will swing a 12" wooden prop.......well it looks big to me!