- Joined

- Jan 19, 2010

- Messages

- 1,193

- Reaction score

- 41

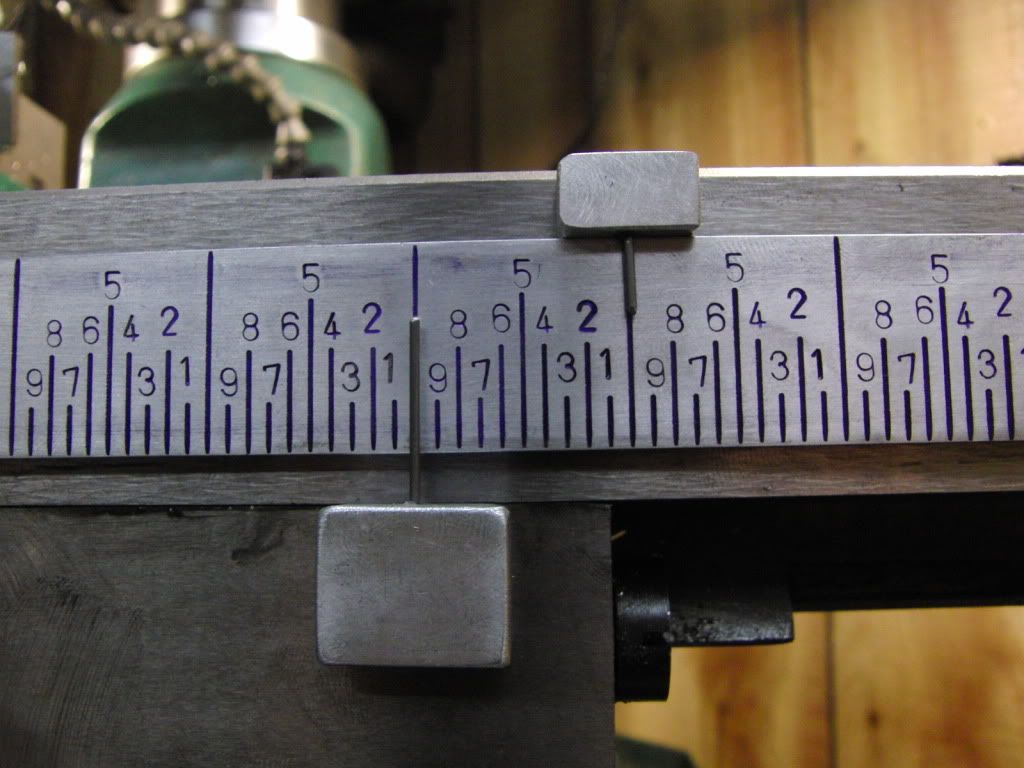

When using the mill table dials, keeping track of how many turns you cranked can be easy to forget if you have allot of milling to do. In the past I have used a small 6 inch ruler with 10th marks on it. This is small, and sometimes not long enough. So I decided it was time to make a better one.

I started with, what els, but a ruler shaped piece of aluminum. 1/8 inch thick, and 13 inches long. (it will be a 12" ruler, but I need room on either end to mount it.

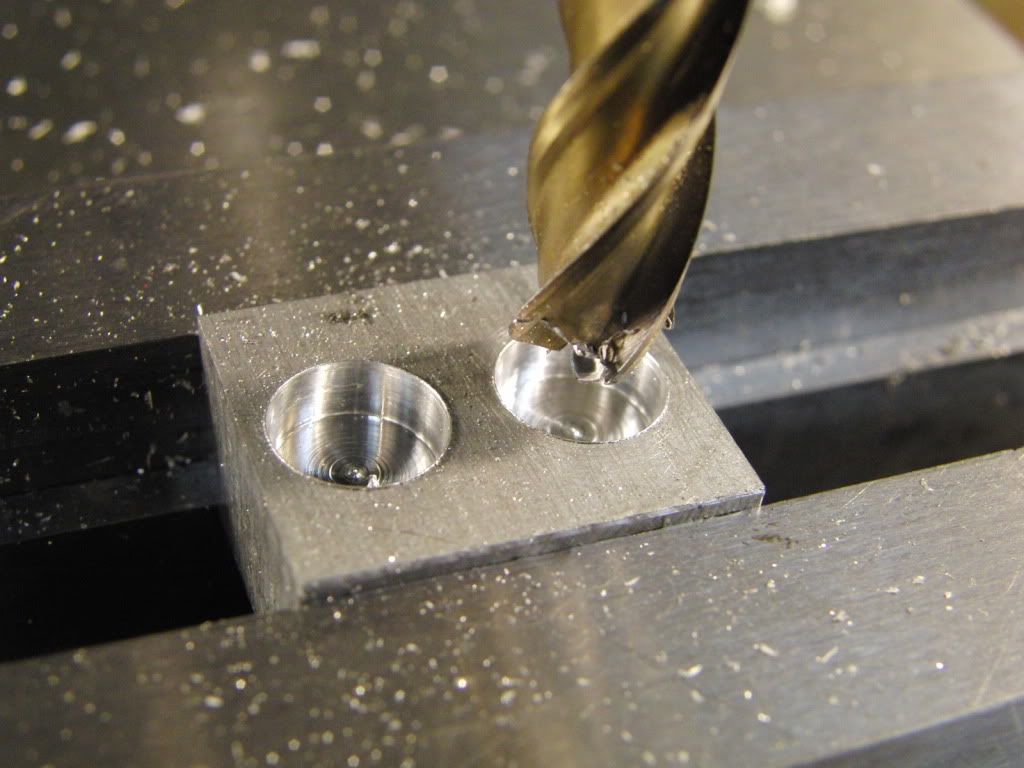

From there It went directly into the mill vise. But Oh no! My vise is only 5" wide. Well since I was not doing any heavy milling, a machinist jack was in order. I used this in combination with a step clamp, to prevent any vibration.

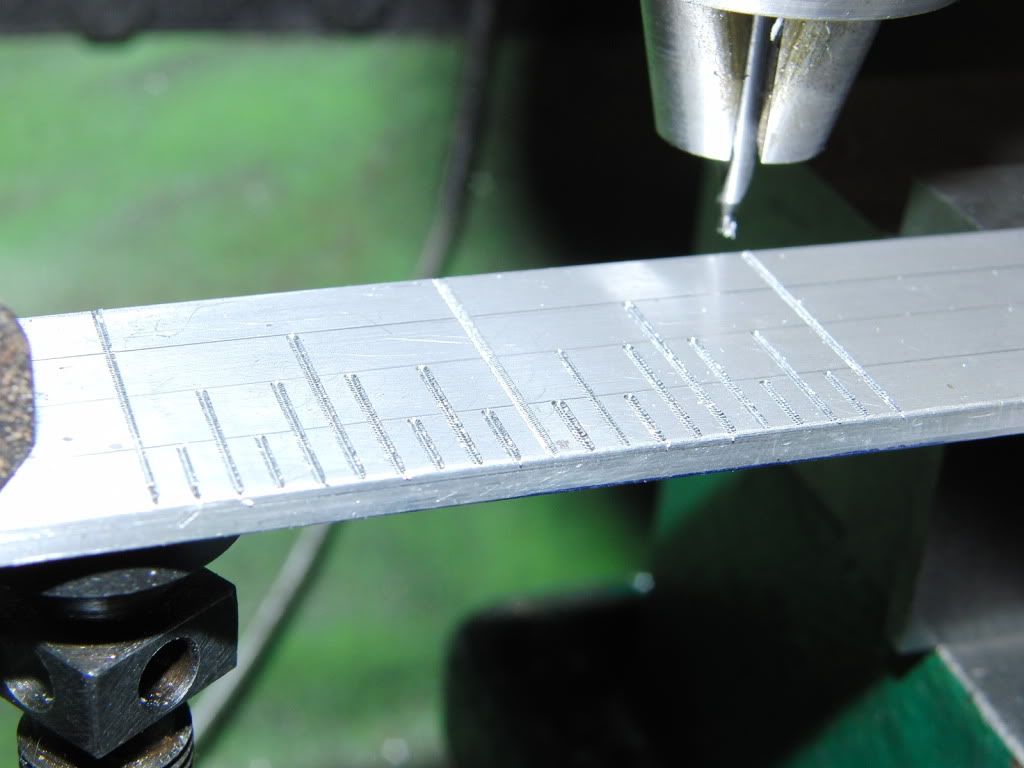

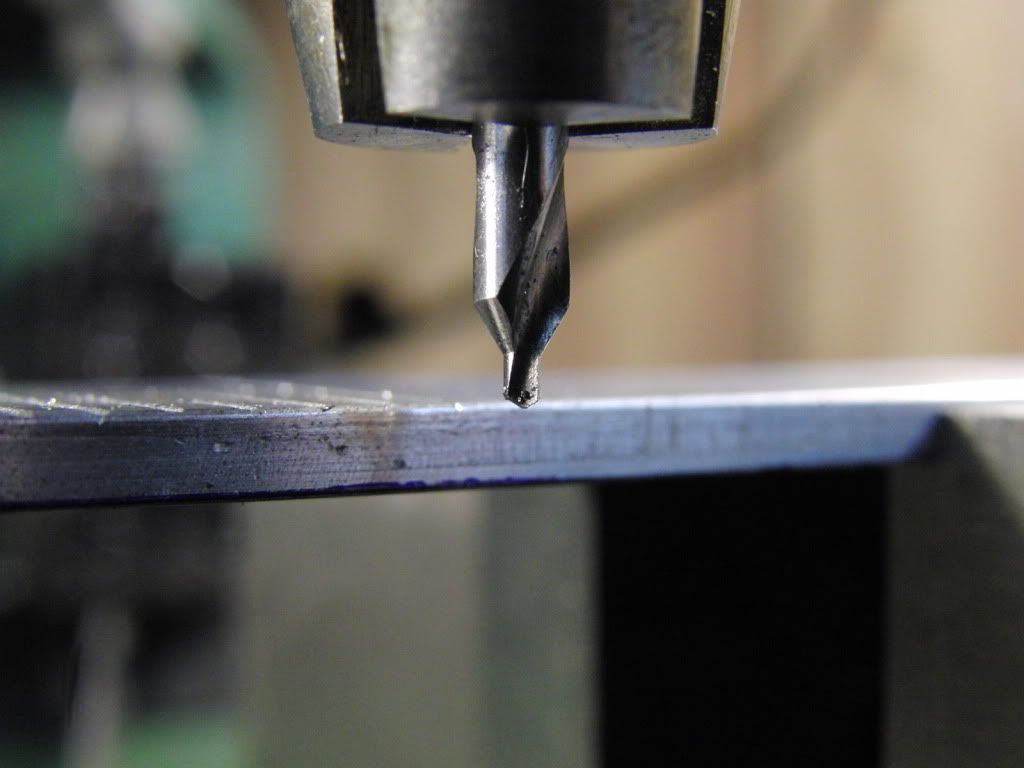

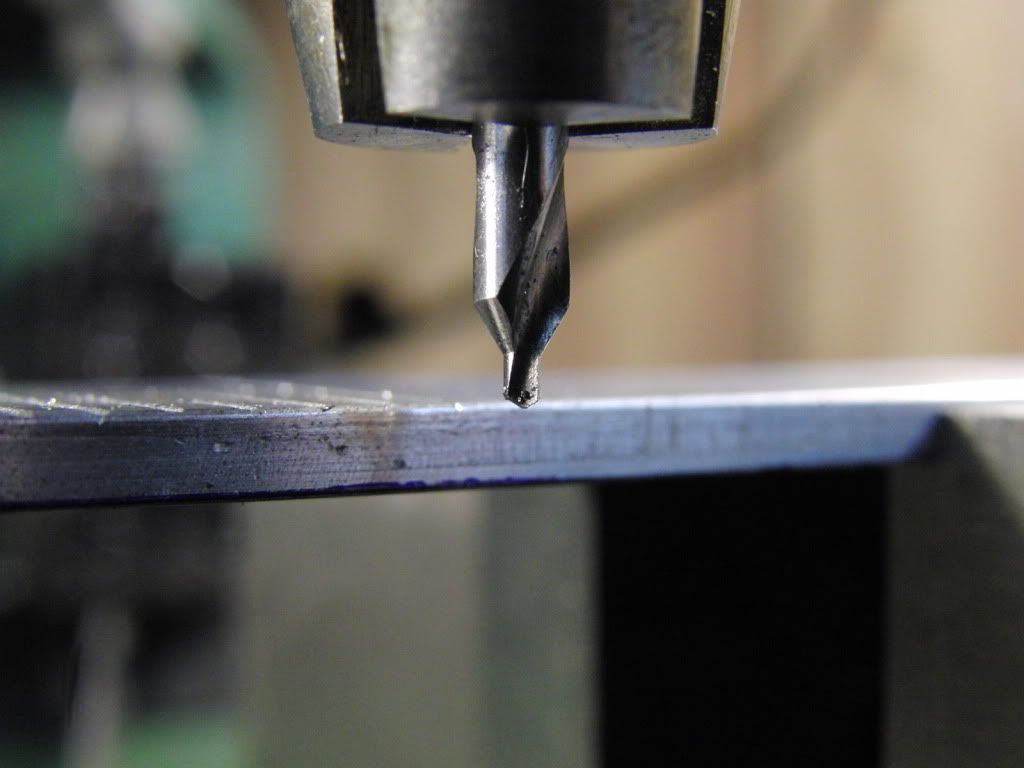

Now its time to make the reference marks on the ruler. I used a #1 center drill, setup to cut about .005" deep.

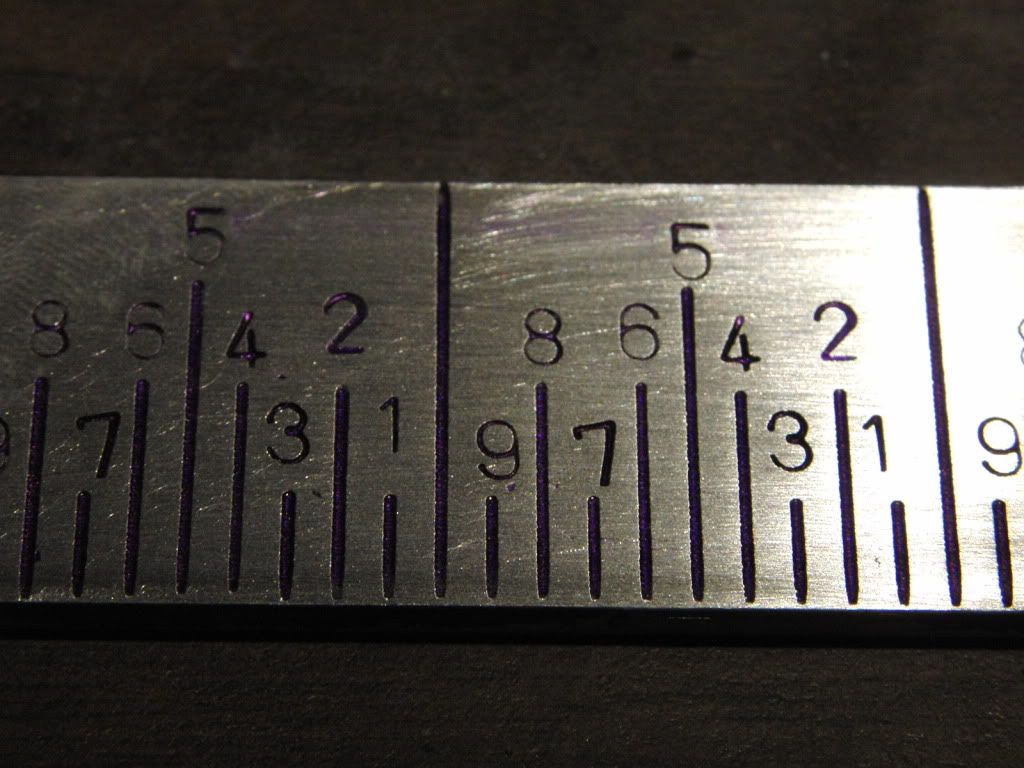

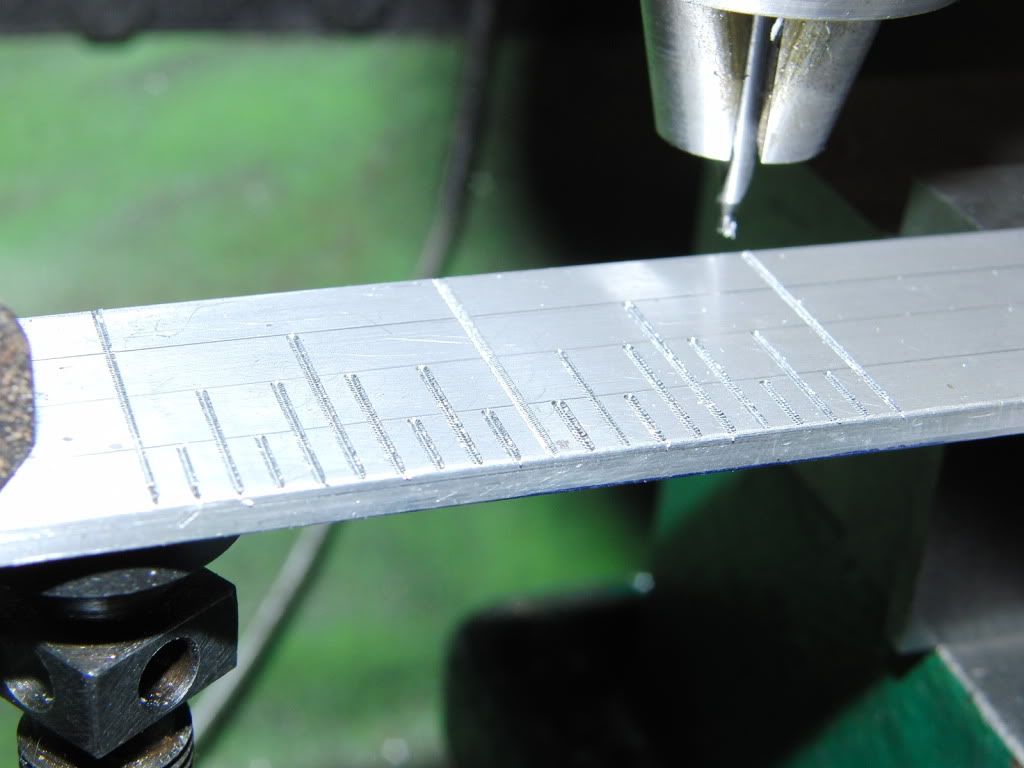

Here are the marks I am making. I marked it out in tenths. Since My table cranks .1" per revolution, This will allow me to know exactly how many revolutions I have made without counting. I staggered them to make room for the number stamps.

I started with, what els, but a ruler shaped piece of aluminum. 1/8 inch thick, and 13 inches long. (it will be a 12" ruler, but I need room on either end to mount it.

From there It went directly into the mill vise. But Oh no! My vise is only 5" wide. Well since I was not doing any heavy milling, a machinist jack was in order. I used this in combination with a step clamp, to prevent any vibration.

Now its time to make the reference marks on the ruler. I used a #1 center drill, setup to cut about .005" deep.

Here are the marks I am making. I marked it out in tenths. Since My table cranks .1" per revolution, This will allow me to know exactly how many revolutions I have made without counting. I staggered them to make room for the number stamps.