DICKEYBIRD

Well-Known Member

- Joined

- Sep 27, 2007

- Messages

- 653

- Reaction score

- 46

Thank goodness for clipboards & lists!

Man, I roared out in the shop this morning, buzzing from a liberal dose of coffee, looked around and realized the floor was clean, no swarf was covering the machines and I had no project started. ???

I'm not ready to start a big project right now and had nothing on my mind to build. I keep an old ragged clipboard under the bench with misc. notes, tools to be bought and projects I bump into that go on a special "Round Tuit" page. On the list was a micrometer stand I saw on somebody's website and wrote it down as something I could use whenever a window of spare time became available.

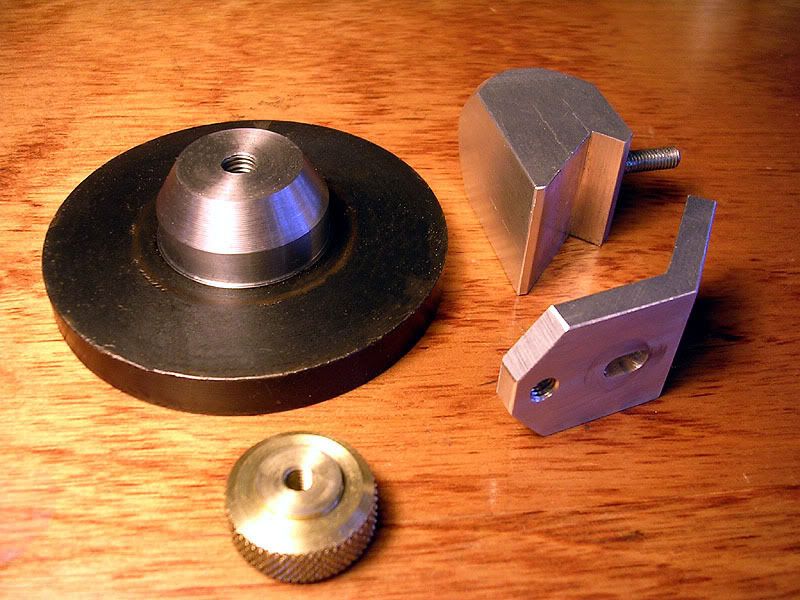

Here's my rendition, made from an old transmission bearing press tool adaptor, a bit of brass and some scrap aluminum. It works well and was free (other than my time.)

Don't make fun of my old battle scarred 1969 vintage mike. It works smooth as silk and is still as accurate as brand new! I wonder if my H/F digital calipers will still be working in 39 years?

Man, I roared out in the shop this morning, buzzing from a liberal dose of coffee, looked around and realized the floor was clean, no swarf was covering the machines and I had no project started. ???

I'm not ready to start a big project right now and had nothing on my mind to build. I keep an old ragged clipboard under the bench with misc. notes, tools to be bought and projects I bump into that go on a special "Round Tuit" page. On the list was a micrometer stand I saw on somebody's website and wrote it down as something I could use whenever a window of spare time became available.

Here's my rendition, made from an old transmission bearing press tool adaptor, a bit of brass and some scrap aluminum. It works well and was free (other than my time.)

Don't make fun of my old battle scarred 1969 vintage mike. It works smooth as silk and is still as accurate as brand new! I wonder if my H/F digital calipers will still be working in 39 years?