mklotz

Well-Known Member

Roy (Shred) asked me about the mathematics of making a tapered flute with a ball mill by tilting the workpiece along the path of the ball mill. For an example of what we're talking about, look at this old thread

http://www.homemodelenginemachinist.com/index.php?topic=612.msg4066#msg4066

where Bogs used the technique to flute the tapered connecting rod of an engine.

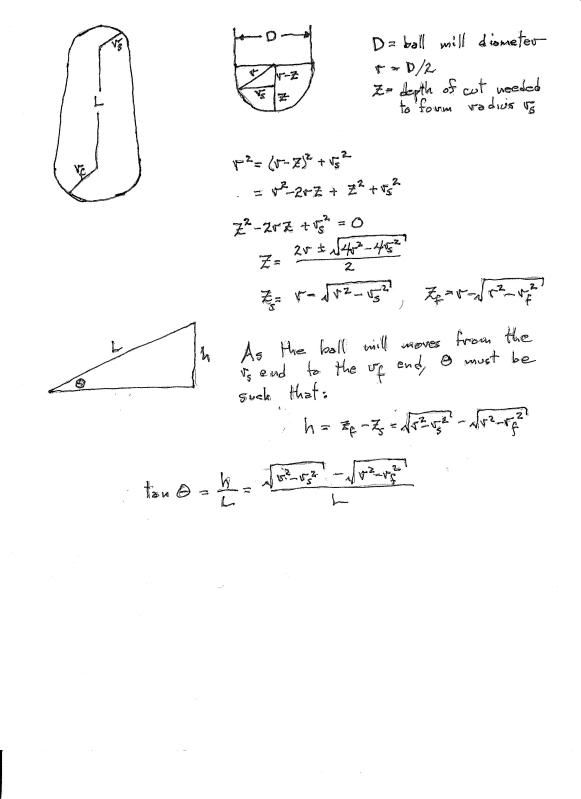

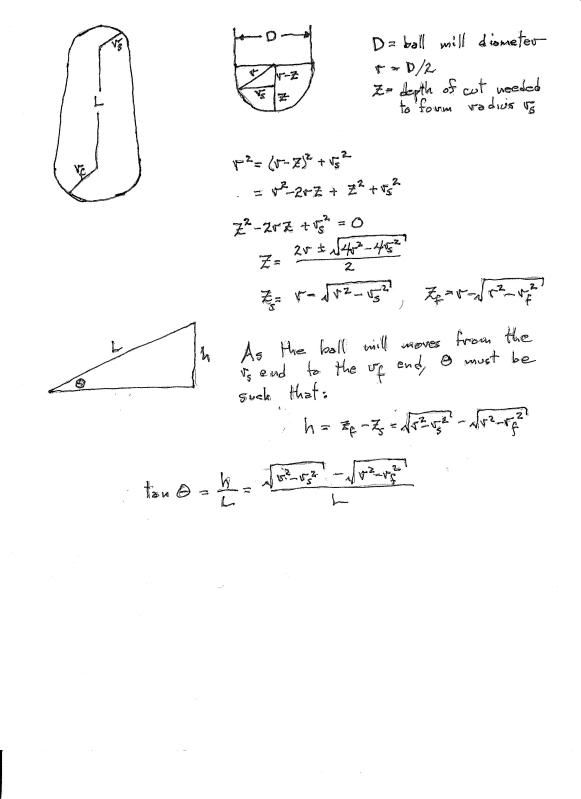

I've derived a mathematical relation for the required tilt of the workpiece as a function of:

the radii at the two ends of the flute

the length of the flute

the diameter of the ball mill

The derivation is very straightforward and the calculation can be done easily on any scientific calculator (the quintessential shop tool) but, if enough people are stupefied by the math, I'll consider putting it together as a program and put it on my page.

http://www.homemodelenginemachinist.com/index.php?topic=612.msg4066#msg4066

where Bogs used the technique to flute the tapered connecting rod of an engine.

I've derived a mathematical relation for the required tilt of the workpiece as a function of:

the radii at the two ends of the flute

the length of the flute

the diameter of the ball mill

The derivation is very straightforward and the calculation can be done easily on any scientific calculator (the quintessential shop tool) but, if enough people are stupefied by the math, I'll consider putting it together as a program and put it on my page.