This watch makers lathe was my great grandfathers which unfortunately was given to me when I was 14 years old with no instructions and no-one to show me how to use it.

So of course I broke it and it was stashed away for the next 20 odd years until I dragged it out again the other day.

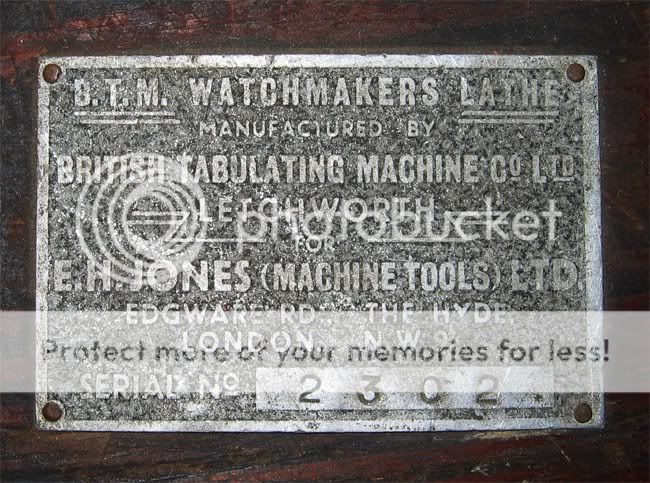

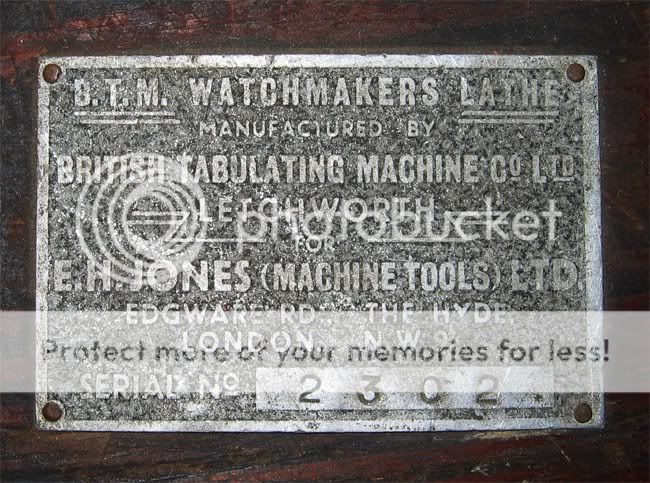

For those that don't know the BTM lathe is a copy of a German lathe as for some odd reason German lathes were hard to obtain in the UK during the early to mid 1940s. ;D

Well enough chat and time for some pictures.

The complete kit with some pliers placed on the bench to give you some idea how small this lathe is.

The box of goodies.

A close up of the chuck and tool rests.

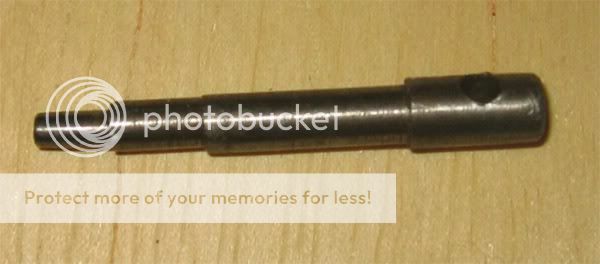

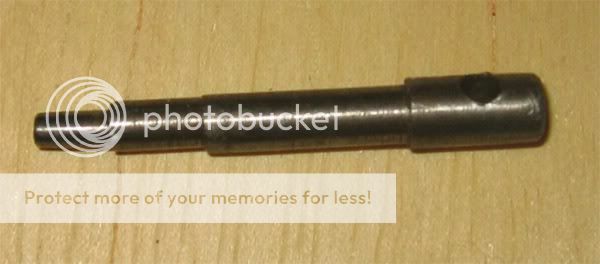

A close up of the offending part that made it be put away 20 odd years ago.

This little pin has the smallest diameter offset from the rest so when it is rotated it locks the top slide at the angle you want to set it at.

Its hard to see in the photo but its bent at the end because as a stupid kid I just forced the top slide to what ever angle I wanted and bent it.

Once I get my dial indicator which I've got on back order at my local shop it should be a quick job to turn up a new pin on my new lathe and then I can see about restoring the rest of the lathe.

If anyone has some good tips about what is the best oil to use to prevent further rust and what is the best way to remove the very minor surface rust of the parts they would be greatly appreciated.

So of course I broke it and it was stashed away for the next 20 odd years until I dragged it out again the other day.

For those that don't know the BTM lathe is a copy of a German lathe as for some odd reason German lathes were hard to obtain in the UK during the early to mid 1940s. ;D

Well enough chat and time for some pictures.

The complete kit with some pliers placed on the bench to give you some idea how small this lathe is.

The box of goodies.

A close up of the chuck and tool rests.

A close up of the offending part that made it be put away 20 odd years ago.

This little pin has the smallest diameter offset from the rest so when it is rotated it locks the top slide at the angle you want to set it at.

Its hard to see in the photo but its bent at the end because as a stupid kid I just forced the top slide to what ever angle I wanted and bent it.

Once I get my dial indicator which I've got on back order at my local shop it should be a quick job to turn up a new pin on my new lathe and then I can see about restoring the rest of the lathe.

If anyone has some good tips about what is the best oil to use to prevent further rust and what is the best way to remove the very minor surface rust of the parts they would be greatly appreciated.