You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Long Stroke Engine

- Thread starter OrangeAlpine

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

MuellerNick

Well-Known Member

- Joined

- Oct 5, 2012

- Messages

- 398

- Reaction score

- 191

I actually think engines with compression ratios as little as 4:1 will operate pretty well

Yes, no complaining about that. I just don't know how tight he will get his piston and valves.

Nick

I don't know either. I'll ask the next time I see him.Yes, no complaining about that. I just don't know how tight he will get his piston and valves.

Nick

But first, a mock up and a lot more thinking is in order.

Bill

By auxiliary exhaust, I mean ports located at the bottom of the cylinder, as in a 2 stroke engine. That leaves less exhaust to exit the undersized valve.

Bill

Bill

MuellerNick

Well-Known Member

- Joined

- Oct 5, 2012

- Messages

- 398

- Reaction score

- 191

I mean ports located at the bottom of the cylinder

Now that is really old-school!

I have never herded or seen such an engine running. I only know that they did it that way in the early days (and quit it). But I really like that idea!

Nick

Wagon173

Senior Member

- Joined

- Dec 4, 2012

- Messages

- 129

- Reaction score

- 32

That's pretty funny nick. What's the fun in taking maybes and wild guesses out of the equasion? Isn't that the spice of life? The CH47 Was nothing but maybes and wild guesses and according to modern aerodynamics, would only fly if someone balled it up and threw it off the drafting board. But I've ridden one and they are awesome. So maybe a little imagination is all you need to go beyond your standard 6:1 protocol.

I not sure (not a clue, really) what you mean. Are you saying I should have a go at a higher CR?That's pretty funny nick. What's the fun in taking maybes and wild guesses out of the equasion? Isn't that the spice of life? The CH47 Was nothing but maybes and wild guesses and according to modern aerodynamics, would only fly if someone balled it up and threw it off the drafting board. But I've ridden one and they are awesome. So maybe a little imagination is all you need to go beyond your standard 6:1 protocol.

Anyone know the octane rating of Coleman fuel?

Bill

Whoa! After a short stint on the old Google Machine, I find the octane rating of Coleman fuel is 50-55. Makes me think that a true CR of 4:1 is about all that stuff can support.

Bill

Bill

Building the engine with higher compression ratio allows some compensation of bad seals (common error source!).

You can easily decrease the compression ratio afterwards by exchanging the head gasket for a bigger one, if compression ratio turns out to be way to high.

You can easily decrease the compression ratio afterwards by exchanging the head gasket for a bigger one, if compression ratio turns out to be way to high.

Speaking of fuels, has anyone tried E85? I know nothing about the stuff, but it is available to me. It seems regular gasoline and Coleman fuel are used, but no talk of other fuels.

Bill

Bill

Whoa! After a short stint on the old Google Machine, I find the octane rating of Coleman fuel is 50-55. Makes me think that a true CR of 4:1 is about all that stuff can support.

Bill

Everything else about the engine design also comes into play. I run kerosene in small engines at 8:1 and even higher. Kerosene is closer to diesel fuel than it is gasoline, and you can't even find an octane rating, it has a cetane rating. E85 is fine, but can cause corrosion compared to a petroleum fuel.

The auxiliary exhuast sounds interesting in it's own right, but this was stopped when they figured out to just open the exhaust valve BBDC. Early engine valve timing didn't make too much sense when we know what we do now.

Wagon173

Senior Member

- Joined

- Dec 4, 2012

- Messages

- 129

- Reaction score

- 32

I'm not saying do or don't. What I was saying is that I wouldn't not do something the way you want to do it because someone thinks it's against standard practice or has an easier way to do it. I'm absolutely brand new to this model engine building but for my day job I work on diesel engines with a 23:1 compression ratio. To achieve that high compression most of our engines use a kerosine based JP8 style of diesel with a cetane number around 35 or so if I remember right. So unless there is something I'm overlooking here, I just don't see why you couldn't do a longer stroke higher compression engine the way you had originally wanted to. Good luck to you whichever way you decide to take this project though!I not sure (not a clue, really) what you mean. Are you saying I should have a go at a higher CR?

Anyone know the octane rating of Coleman fuel?

Bill

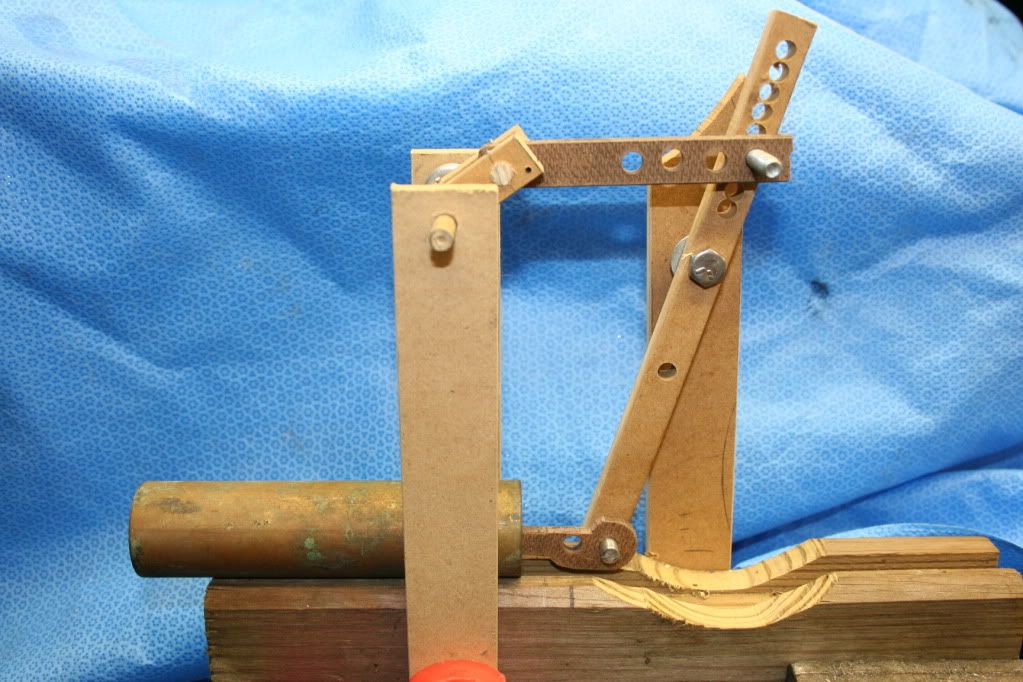

As promised, I have given this engine quite a bit of thought. It was obvious it was going to be long and spindly looking. After much thinking and a couple of nightmares, this is what I came up with:

Gentleman, meet Funky.

A horizontal gasoline beam engine.

A few more photos of the engine as it goes through one rotation.

The bore is 1 1/8", stroke 3 3/4", crank throw 3/4" (1 1/2" stroke of the connecting rod. Keep in mind this is the crudest of mock ups, done to get a feel of the concept. The rest of the engine would be totally conventional, with the exception of the auxiliary exhaust. Any ideas or comments?

Bill

Gentleman, meet Funky.

A horizontal gasoline beam engine.

A few more photos of the engine as it goes through one rotation.

The bore is 1 1/8", stroke 3 3/4", crank throw 3/4" (1 1/2" stroke of the connecting rod. Keep in mind this is the crudest of mock ups, done to get a feel of the concept. The rest of the engine would be totally conventional, with the exception of the auxiliary exhaust. Any ideas or comments?

Bill

MuellerNick

Well-Known Member

- Joined

- Oct 5, 2012

- Messages

- 398

- Reaction score

- 191

A beam engine, that has fallen over.

I would limit the tilting of the vertical lever to +/- 30°. Things start to bind if you go higher.

Since long, I like the idea of a super long stroke, but I didn't build anything. I'll watch your progress.

Nick

I would limit the tilting of the vertical lever to +/- 30°. Things start to bind if you go higher.

Since long, I like the idea of a super long stroke, but I didn't build anything. I'll watch your progress.

Nick

Bill look into the designs of Hamilton "Dick" Upshur

http://hamiltonupshur.tripod.com/

these engines are 3/4 bore.

Tin

I have mentioned this before on this forum and I am attempting to tie up all the loose ends, but I am the grandson of Hamilton Upshur and I have been working with my Aunt to redo the website where his plans are sold. Tripod is quite dated and the advertisements just make the site unreadable. In the process of fixing this the website has moved locations

UpshurEngineWorks.com

this is the new web address for Upshur Engine Works. you will notice it looks identical to the old site, minus the nasty ads. Hopefully this will continue to suffice as I work as hard as I can to put together a new and improved site.

If anyone knows any other place on the internet where the old web address is still advertised can you please change it or bring it to my attention. I can be emailed directly at [email protected]

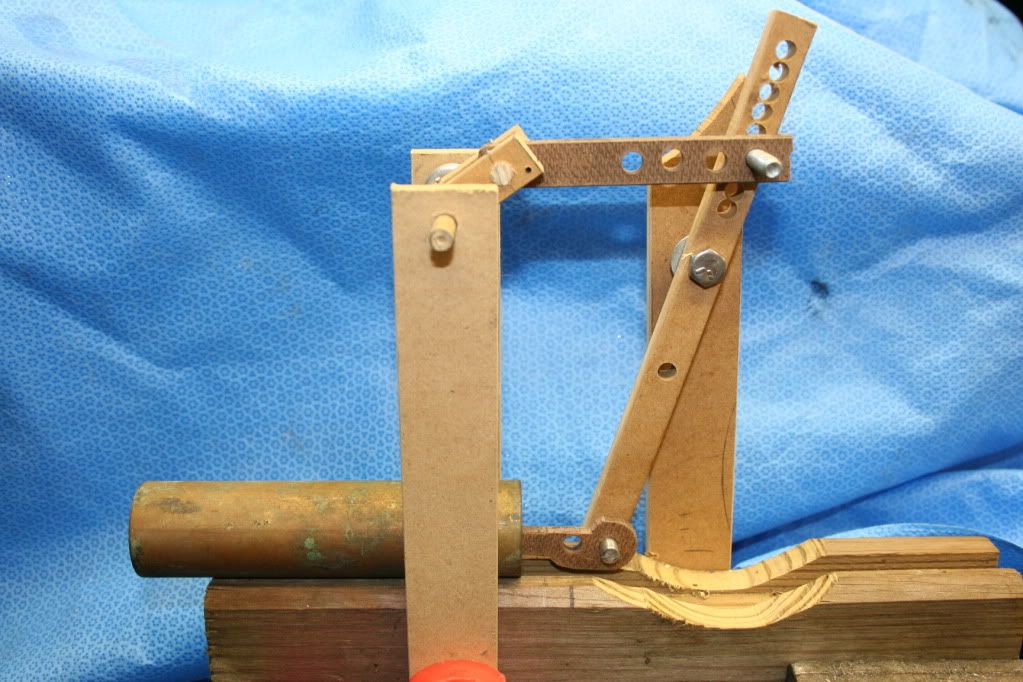

I took Nick's advice and lengthened the lever. The action was not binding, but was somewhat herky-jerky. It is now much smoother.

I had an idea that I pursued. Here it is.

The action is the same. I like the original because it is somewhat self balancing. I like the second one because it is more compact.

Opinions? Keep in mind this is to be built only as an oddball, although I do want to keep it mechanically sound.

Bill

I had an idea that I pursued. Here it is.

The action is the same. I like the original because it is somewhat self balancing. I like the second one because it is more compact.

Opinions? Keep in mind this is to be built only as an oddball, although I do want to keep it mechanically sound.

Bill

Hmmm. Several lookers, no opinions.

After further cogitation, I really like the idea of balancing the engine using reciprocating weight rather than rotating weight. How about using the "lever" engine design, but with a counterweight on the end of the beam?

Any thoughts on which design would make the most interesting engine?

Bill

After further cogitation, I really like the idea of balancing the engine using reciprocating weight rather than rotating weight. How about using the "lever" engine design, but with a counterweight on the end of the beam?

Any thoughts on which design would make the most interesting engine?

Bill

MuellerNick

Well-Known Member

- Joined

- Oct 5, 2012

- Messages

- 398

- Reaction score

- 191

I like the second one because it is more compact.

Looks better to me. With the first setup, the flywheel is quite up in the sky. The second one looks more natural.

As it is now, stop playing around and make chips!

Just my opinion.

Nick

Thank you Nick.Looks better to me. With the first setup, the flywheel is quite up in the sky. The second one looks more natural.

As it is now, stop playing around and make chips!

Just my opinion.

Nick

There's only one problem with making chips: I have no idea how I'm actually going to make the thing. So far, this has been an exercise to determine proof of concept and gain some idea of proportion. In fact, I'm thinking I will have to pursue a wooden mockup a little further, something that is actually made to predetermined size and conformation!

Unless, or course, someone comes up with drawings.

Bill

Similar threads

- Replies

- 2

- Views

- 315

- Replies

- 1

- Views

- 914