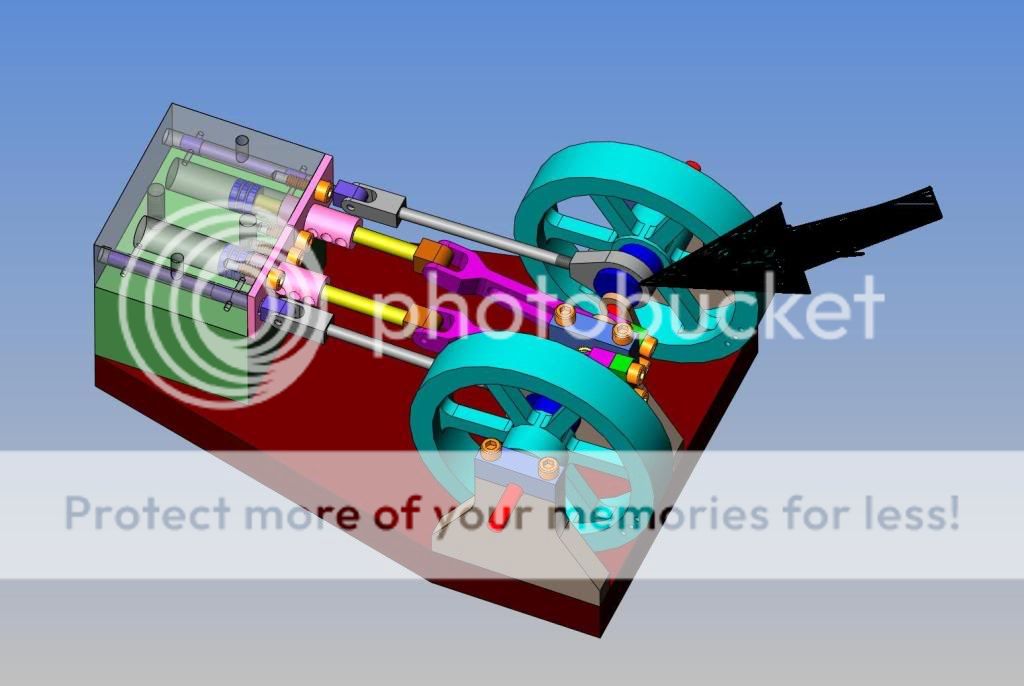

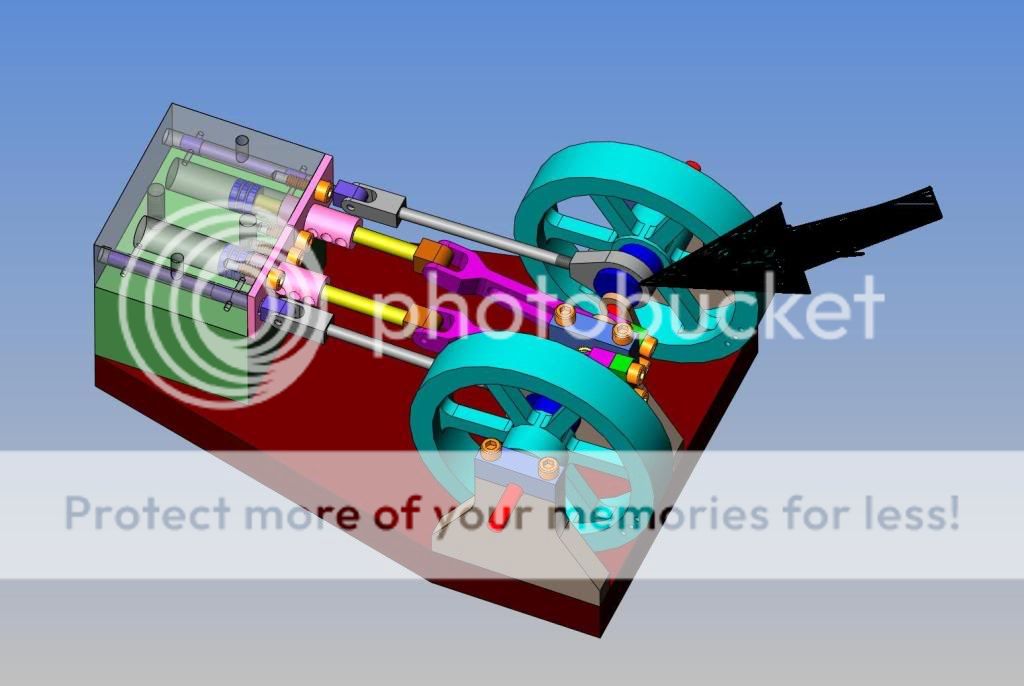

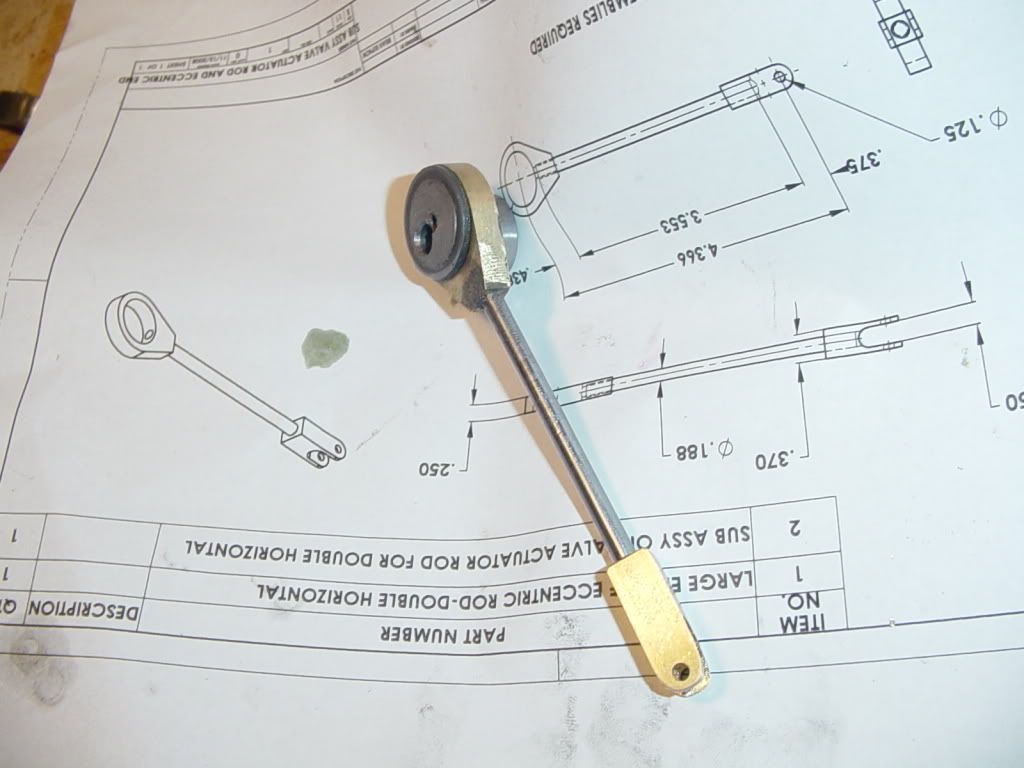

I have been rather intrigued with the way Gail from New Mexico makes his eccentrics in two peices bolted together, with a flange on the eccentric to keep the eccentric strap from wandering off the eccentric. I didn't want to do the extra work involved with making 2 peice eccentrics, but as I was looking at the twin horizontal I am currently building, I noticed that I had made the eccentric about .15" longer than the eccentric strap itself. Suddenly a light came on!! I am going to make up a ring 0.100 thick from mild steel and bore it a couple of thou smaller than the eccentric diameter, then after I have the eccentric strap "fitted" properly to the eccentric, I will heat the ring cherry red and place it over the outboard end of the eccentric. Theory is, it should cool and shrink in place, effectively creating a flange to hold the eccentric strap in place. Whatcha think???