rake60 said:Nice Workbench tmuir!

My wife wants to know if you do kitchens?

That is beautiful wood working!

Rick

My wife has already put her order in I told her to expect a delivery date somewhere between 18 and 24 months. :big:

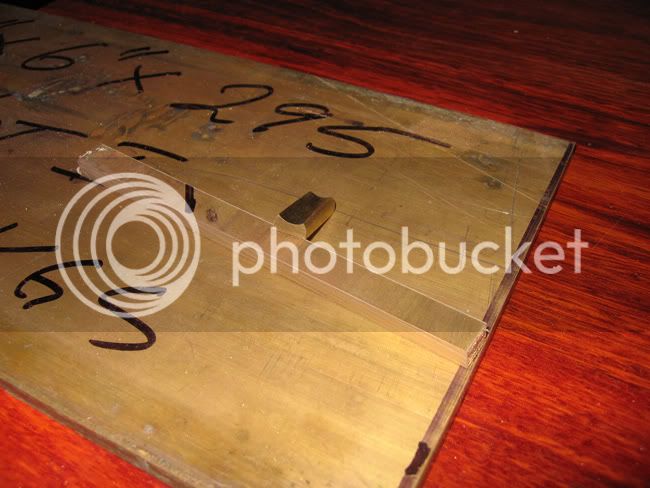

Its not quiet finished yet, it still needs one (or maybe two) coats of varhish yet and then will need to be left for a week or two for the varnish to really cure but this will give you an idea of the finished product.

And yes I am aware of the spot on the edge I missed with the second coat. :

I was about to give it its third and final coat but noticed a run and tried to sand it back and broke through the skin of the varnish to the tacky underneath so now I need to wait a few days for that to properly set so I can sand that bit back before giving the top coat.

I've decided this bench is too nice to fit the vice to now and luckily have just aquired myself a nice bit of 40mm laminated chipboard that I will fit to my small stainless steel bench and put the vice on that.