lazylathe said:What i do know is that everytime i remove the headstock or use it to turn angles i end up rechecking everything to ensure it is as aligned as i can get it with my limited knowledge.

What i am trying to avoid is having to do this everytime i need to mill something, if i was to get an attachment i would have to reset and check evrything evrytime i changed.

Lazylathe, the kind of milling attachment I think most people here are talking about is a unit that mounts directly to the lathe cross slide, and you don't have to disturb your head stock at all. I know the type that Sherline offers, but you can adapt other types to your lathe easily.

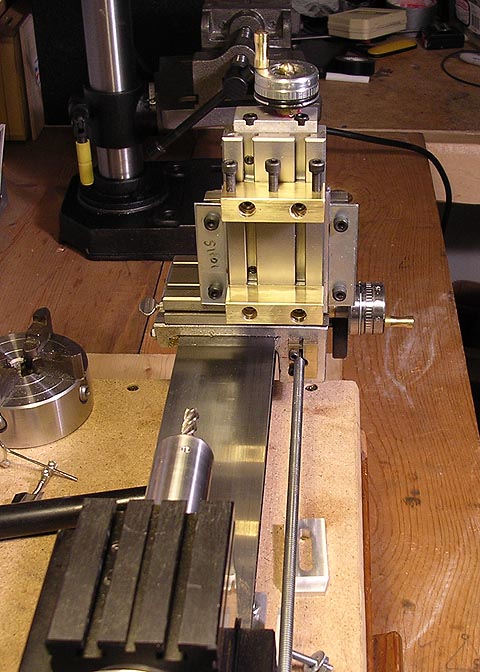

This is one I made for my Taig, using their compound slide accessory, ($45) and an angle block, (about $10):

I have a "how-to" write up on it at the following link:

http://www.deansphotographica.com/machining/projects/millingattachment.html

You can also get an accessory vise for it, like the one from Taig or Sherline, to make your work holding a little easier.

The whole point is, you don't have to remove the head stock from your lathe. Just bolt this rig onto the cross slide and use collets or end mill holders in the spindle, and you're ready to mill away. This is the type of set up that has been used for milling on the lathe for 100 years on lathes like Myford, South Bend, et al.

Dean