dparker

In Rembrance 8/2021

- Joined

- Aug 24, 2007

- Messages

- 218

- Reaction score

- 5

Hello All: Caution---several pictures! Hopefully they can explain better than my description.

In the 1970's I met Mr. Marlyn Hadley at the Steamup at Antique Powerland in Brooks Oregon. He had a display of many model steam engines that he had built over the years. His work was very good and eventually it was shown at the GEARS shows here in the Pacific Northwest. He had been persuaded by his family to make up a book with photos and descriptions of several of his engines. The book is MODEL MACHINES Replicas Steam Models. I bought a copy in the late 80's and bought another newer edition several years later. (gave the first one to a interested High School student)

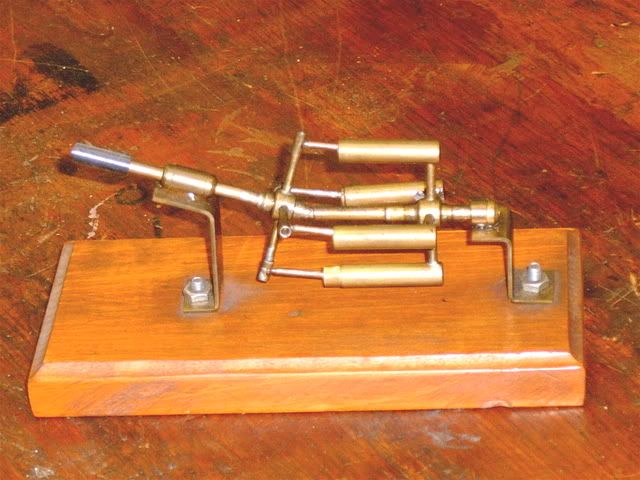

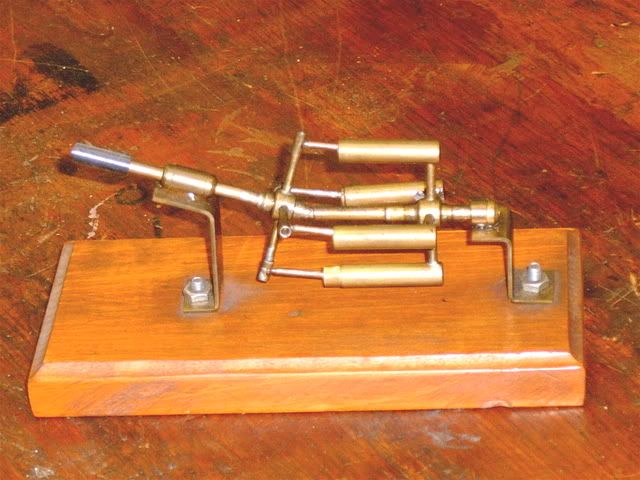

In the last several pages of the book he had pictures and a short writeup of some of the special tooling he had built to use building his models. This faceplate is from his book and machined to fit on my 1968 Craftsman/Atlas 12" x 36" lathe.

My faceplate is 10 3/8" diameter, the "V" block is 2" top to bottom, 3 1/2" wide and 2 1/4" long. It is locked in the desired location by the slides being tightened down and clamping it to the faceplate. A homemade angleplate can be bolted to the block to extend the flat to hold longer cylinders or whatever is being bored.

I hope these pictures will be some help to anybody that desires to build a faceplate like this. All of my material was hot rolled mild steel, The counter balance is a guess as to size to best compensate the unbalance of the position of the "V" block and the piece being machined.

Thank you for taking the time to look at the pictures.

This did not seem to go the first time, will post again, sorry if it double posts.

don

In the 1970's I met Mr. Marlyn Hadley at the Steamup at Antique Powerland in Brooks Oregon. He had a display of many model steam engines that he had built over the years. His work was very good and eventually it was shown at the GEARS shows here in the Pacific Northwest. He had been persuaded by his family to make up a book with photos and descriptions of several of his engines. The book is MODEL MACHINES Replicas Steam Models. I bought a copy in the late 80's and bought another newer edition several years later. (gave the first one to a interested High School student)

In the last several pages of the book he had pictures and a short writeup of some of the special tooling he had built to use building his models. This faceplate is from his book and machined to fit on my 1968 Craftsman/Atlas 12" x 36" lathe.

My faceplate is 10 3/8" diameter, the "V" block is 2" top to bottom, 3 1/2" wide and 2 1/4" long. It is locked in the desired location by the slides being tightened down and clamping it to the faceplate. A homemade angleplate can be bolted to the block to extend the flat to hold longer cylinders or whatever is being bored.

I hope these pictures will be some help to anybody that desires to build a faceplate like this. All of my material was hot rolled mild steel, The counter balance is a guess as to size to best compensate the unbalance of the position of the "V" block and the piece being machined.

Thank you for taking the time to look at the pictures.

This did not seem to go the first time, will post again, sorry if it double posts.

don