Once upon a time Dean showed how he touches up chipped carbide cutters...

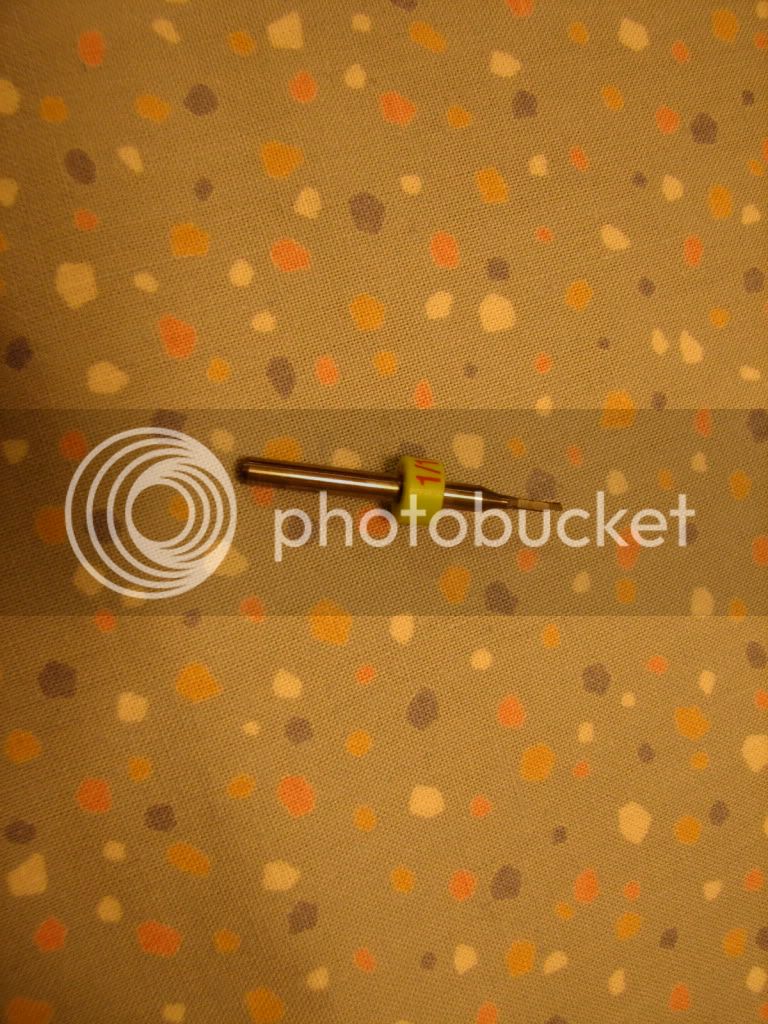

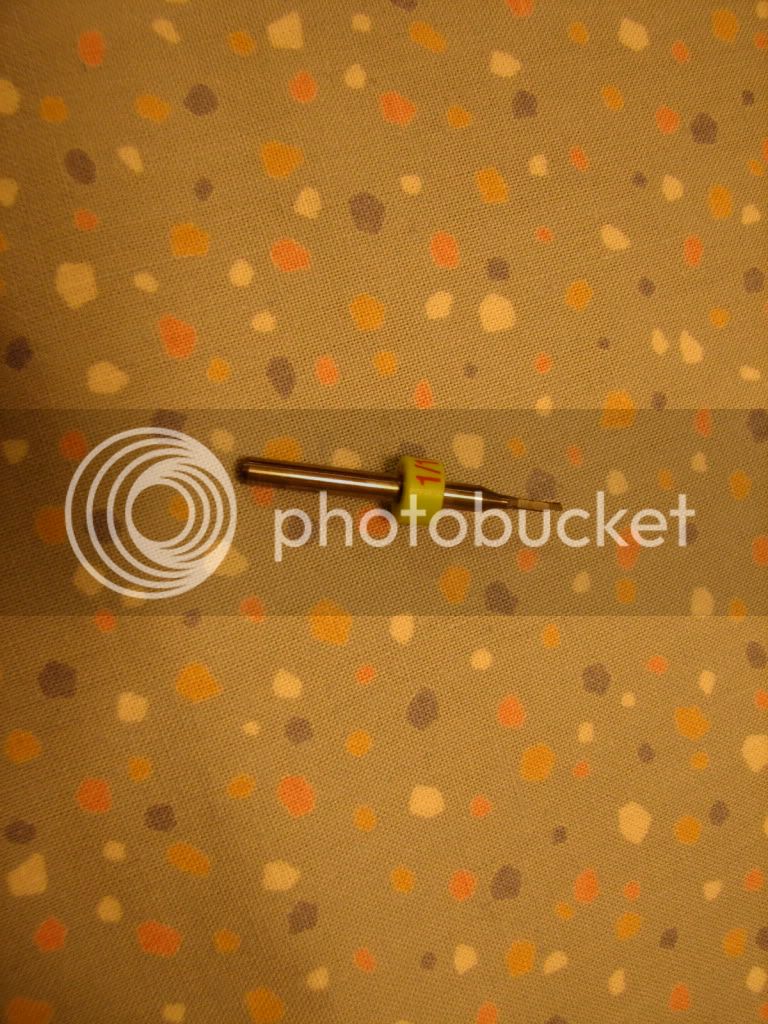

I took his cue and ground a chipped 1/16 solid carbide endmill to make a miniature boring bar... have you seen for how much they go? With the one shown here I can easily bore 0.064" holes -- such as the hole for the cylinder of my 1/4 size version of Elmer's tiny... and of course I can make an even smaller version...

This is the setup on my old Sherline... I show a green carbide wheel -- but ended up using a little diamond disk... I cover the bed for the dust... The Dremel holder is made so that the spindle axis of the lathe and the ... axis of the wobble cone of the rotary tool are in the same height (within 5 thou... - the runout of the rotary is so big that it does not matter...)

the ground bar... sorry for the quality of the photo

Some closeups

another shot...

I think that I will have to make a mini tool grinder... Achim made a looooooovely one...

Oh well,

one part at a time...

take care,

tom in MA

I took his cue and ground a chipped 1/16 solid carbide endmill to make a miniature boring bar... have you seen for how much they go? With the one shown here I can easily bore 0.064" holes -- such as the hole for the cylinder of my 1/4 size version of Elmer's tiny... and of course I can make an even smaller version...

This is the setup on my old Sherline... I show a green carbide wheel -- but ended up using a little diamond disk... I cover the bed for the dust... The Dremel holder is made so that the spindle axis of the lathe and the ... axis of the wobble cone of the rotary tool are in the same height (within 5 thou... - the runout of the rotary is so big that it does not matter...)

the ground bar... sorry for the quality of the photo

Some closeups

another shot...

I think that I will have to make a mini tool grinder... Achim made a looooooovely one...

Oh well,

one part at a time...

take care,

tom in MA