DICKEYBIRD

Well-Known Member

- Joined

- Sep 27, 2007

- Messages

- 653

- Reaction score

- 46

Getting close to the end of my shop tool project list so I can begin a home built model engine from bar stock....I promise!

The disc sander table and bracketry was built for an old 1/4 hp motor I've had lying around for over 20 yrs. doing nothing. It's time to put it to work.

The hole to clear the motor end bearing boss was the biggest one I've done so far with my new boring head. Had to slow it way down but it did a good job. Bunch of swarf generated when you open up a 2" hole (biggets holesaw I had) to over 3".

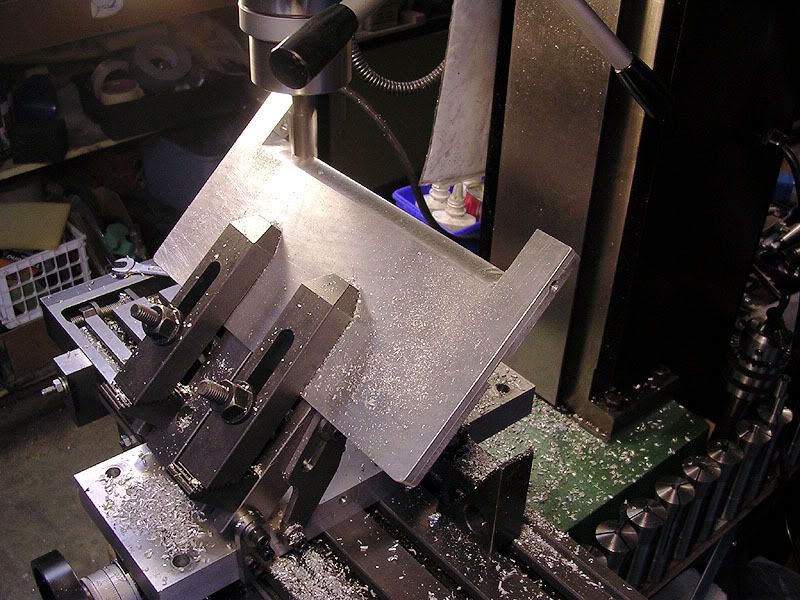

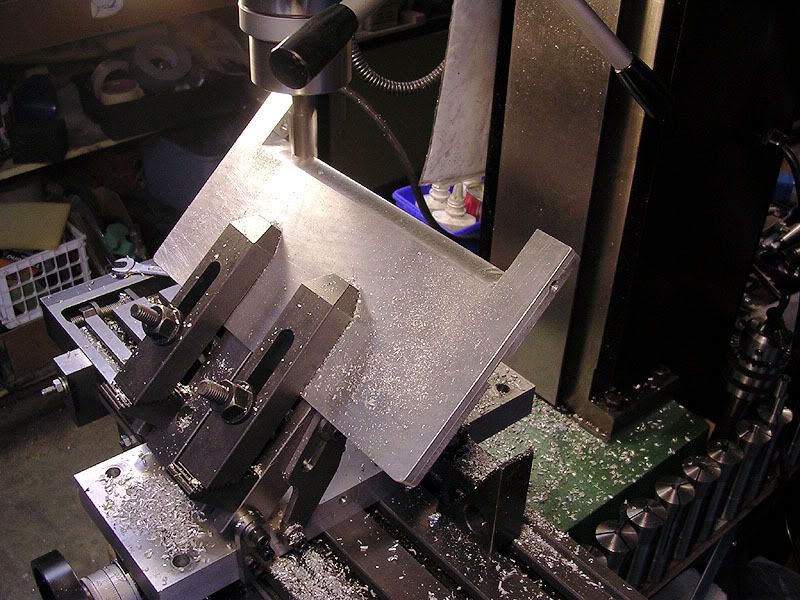

The table pivots so the back side had to have a 45 deg. relief milled using nice Mr. Ishimura's "Tilting Angle Table" design. It worked great even with this flimsy set-up.

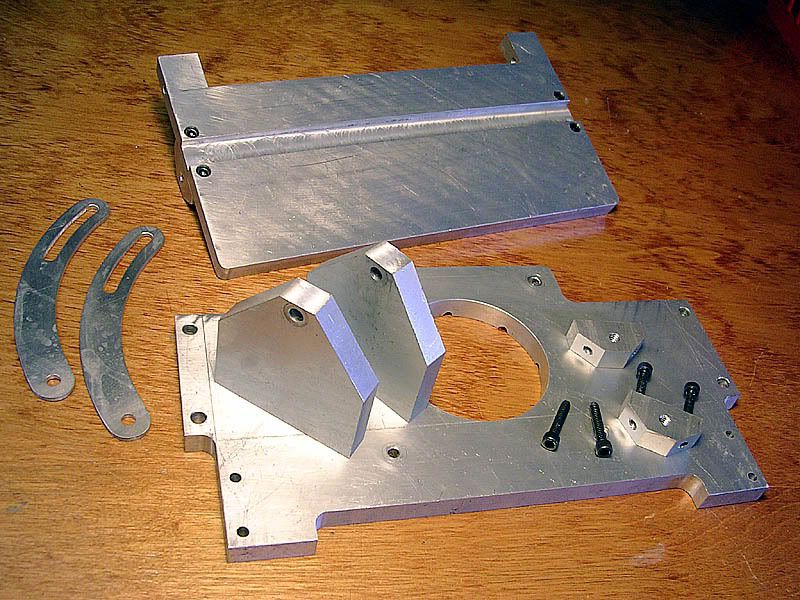

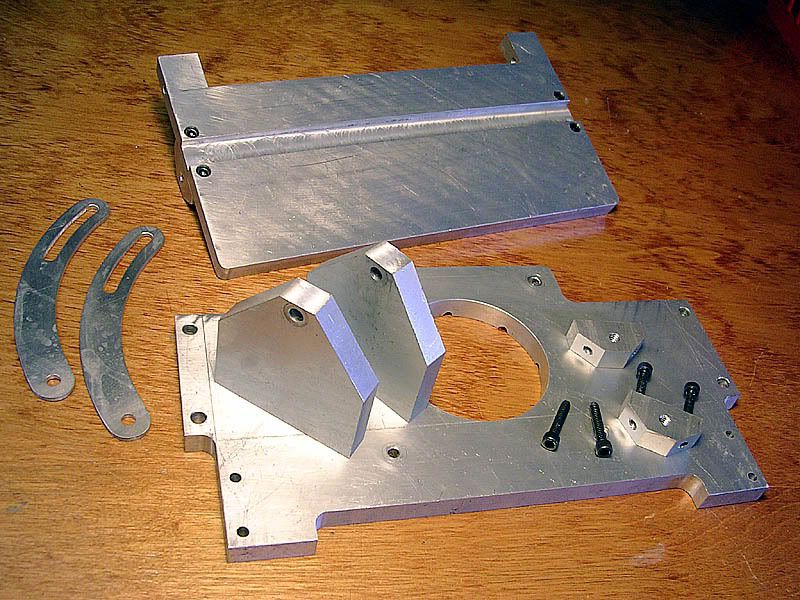

Here's the finished parts. A very generous fellow (Bill Pace) over on the HSM forum sent me an aluminum disc and a few PSA 100 grit discs for nuttin'....nice guy!

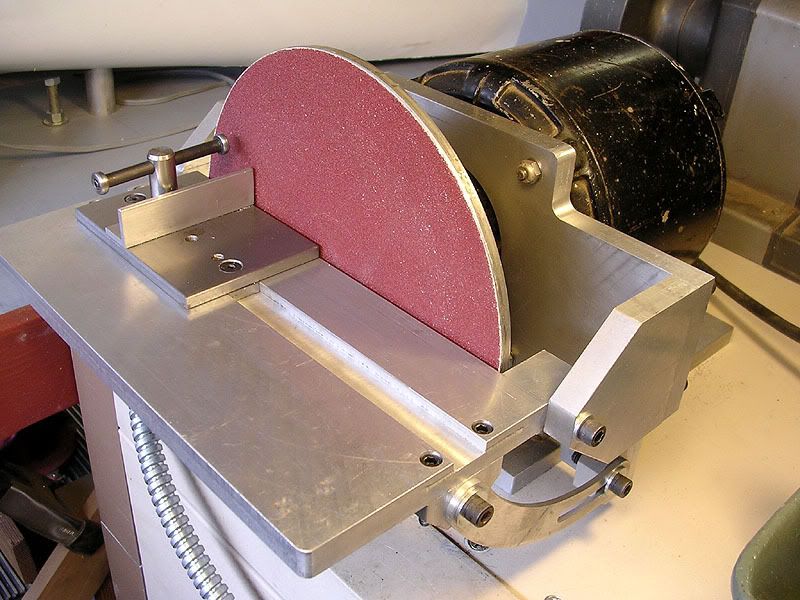

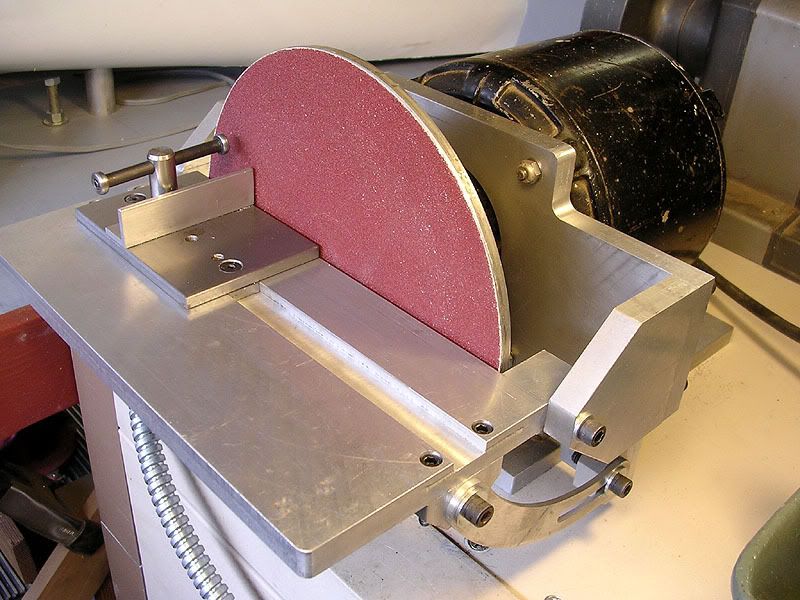

....and the finished assembly:

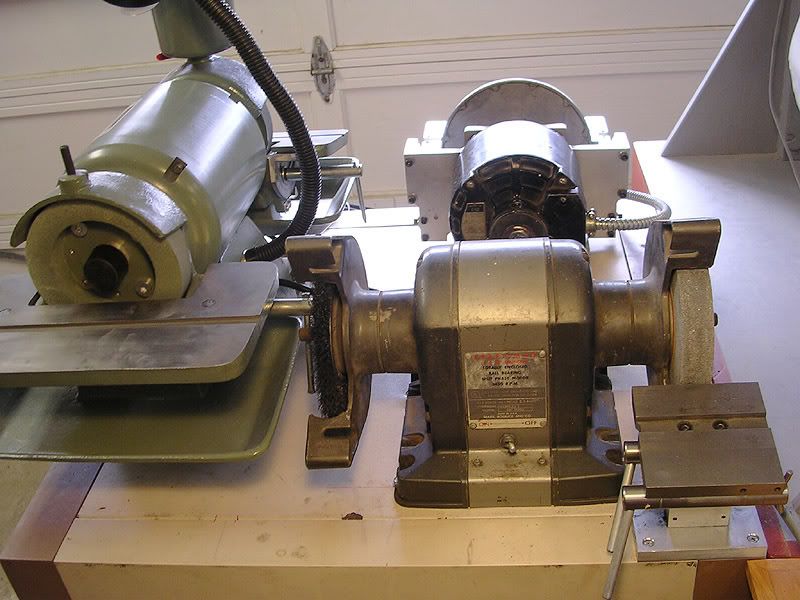

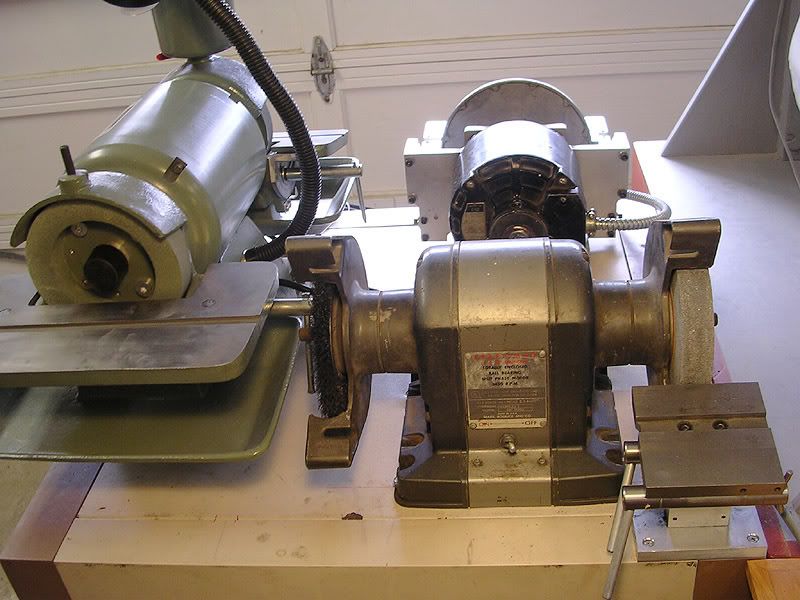

I mounted it alongside of the other 2 grinders on the cabinet described elsewhere on the forum.

It works very well and should do even better when I get some 80 grit zirconium oxide discs.

The disc sander table and bracketry was built for an old 1/4 hp motor I've had lying around for over 20 yrs. doing nothing. It's time to put it to work.

The hole to clear the motor end bearing boss was the biggest one I've done so far with my new boring head. Had to slow it way down but it did a good job. Bunch of swarf generated when you open up a 2" hole (biggets holesaw I had) to over 3".

The table pivots so the back side had to have a 45 deg. relief milled using nice Mr. Ishimura's "Tilting Angle Table" design. It worked great even with this flimsy set-up.

Here's the finished parts. A very generous fellow (Bill Pace) over on the HSM forum sent me an aluminum disc and a few PSA 100 grit discs for nuttin'....nice guy!

....and the finished assembly:

I mounted it alongside of the other 2 grinders on the cabinet described elsewhere on the forum.

It works very well and should do even better when I get some 80 grit zirconium oxide discs.