You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hit and miss STEAM ENGINE????

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

tel

Well-Known Member

- Joined

- Feb 8, 2008

- Messages

- 3,293

- Reaction score

- 44

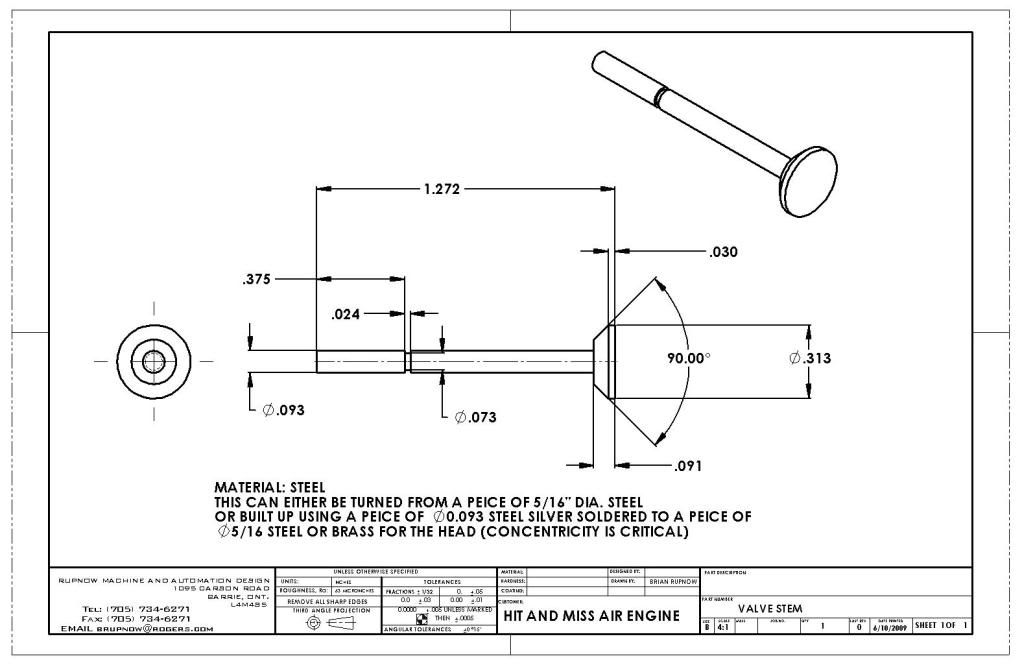

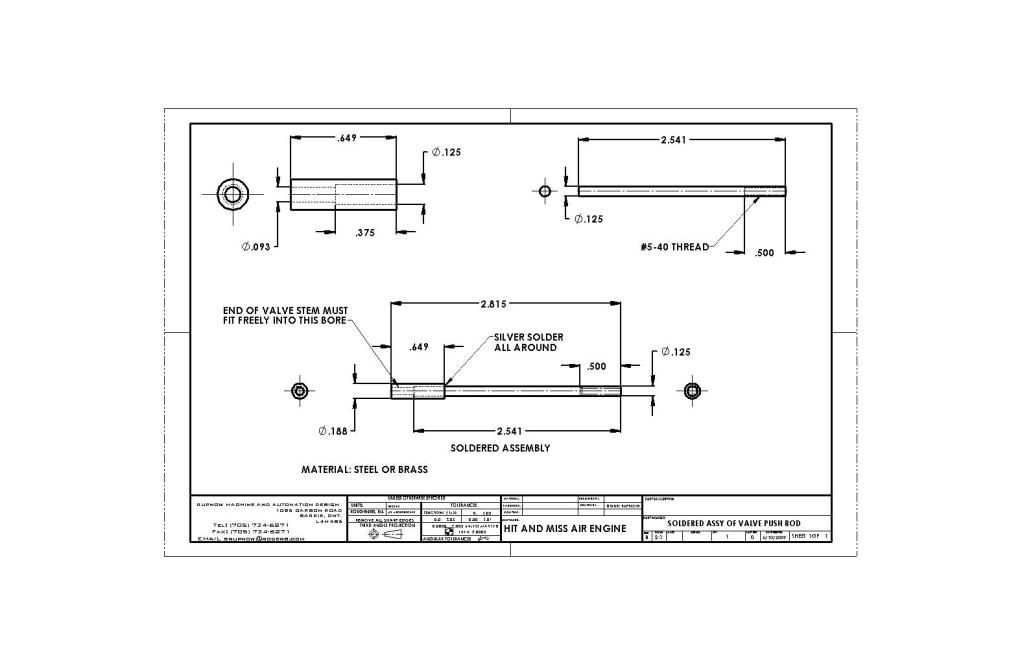

I'm still not totally clear on the connection between the valve stem and the push rod which activates it, but that will come.

Shouldn't need a connection Brian, just a means of keeping them lined up with each other (think automotive valve rocker/push rod)

Looking good so far mate, time to start makin' chips!!!! ;D

Due to bad economy, global warming, and the fact that I only have a small peice of brass and lots of aluminum, is their any real issue with making the cylinder from aluminum and the piston from brass? I have always done the reverse of this on previous engines, but I believe that for the small amount that these engines actually run, I will be old and dead before the aluminum cylinder wears enough to cause any running issues.---Opinions?????????

tel said:Shouldn't need a connection Brian, just a means of keeping them lined up with each other (think automotive valve rocker/push rod)

Looking good so far mate, time to start makin' chips!!!! ;D

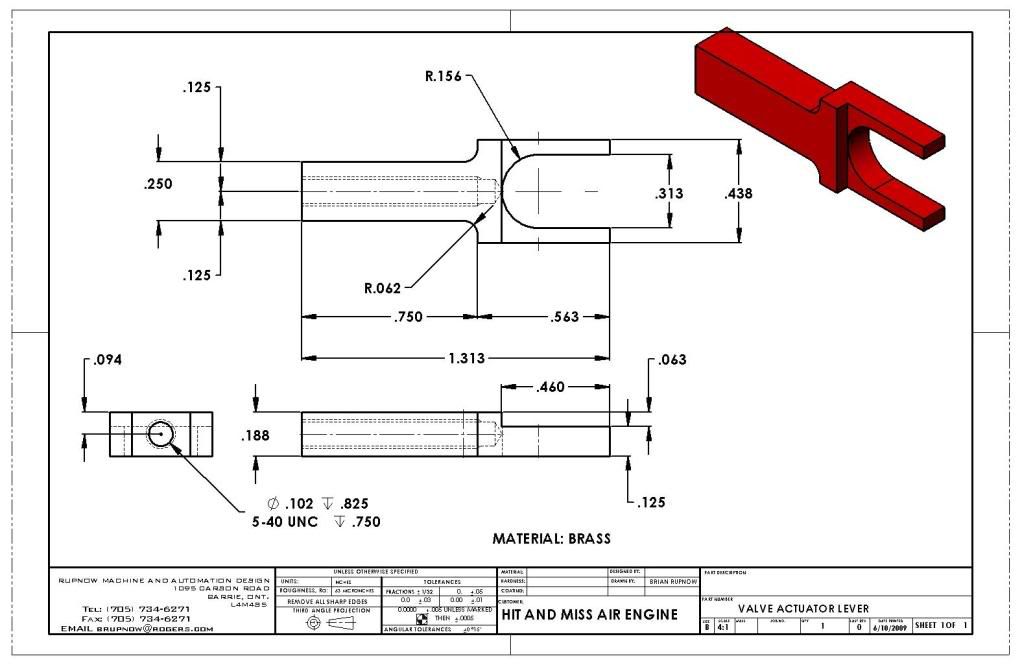

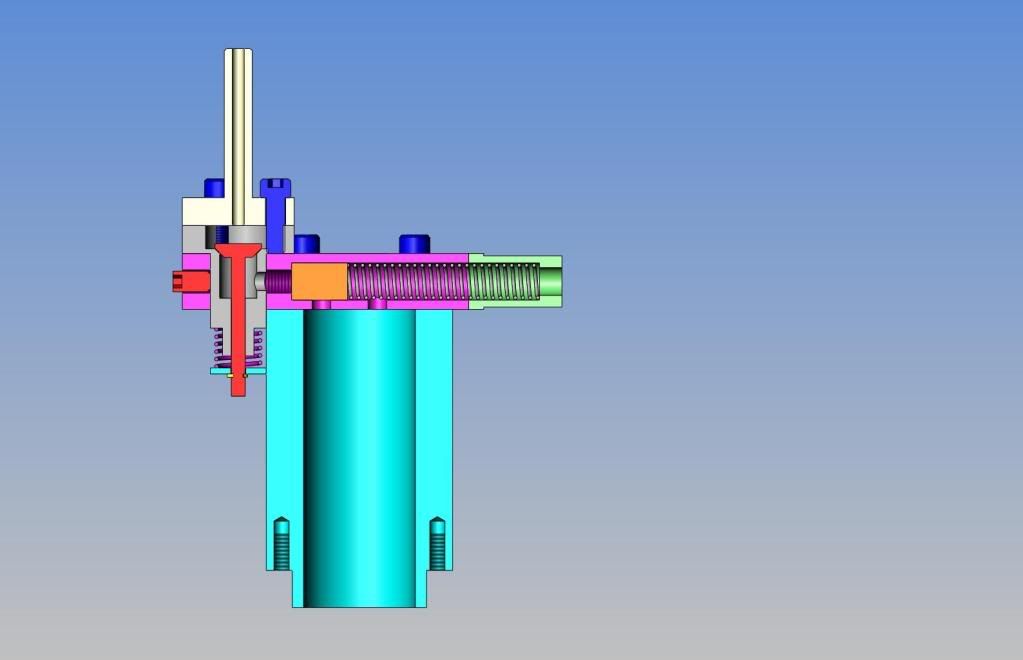

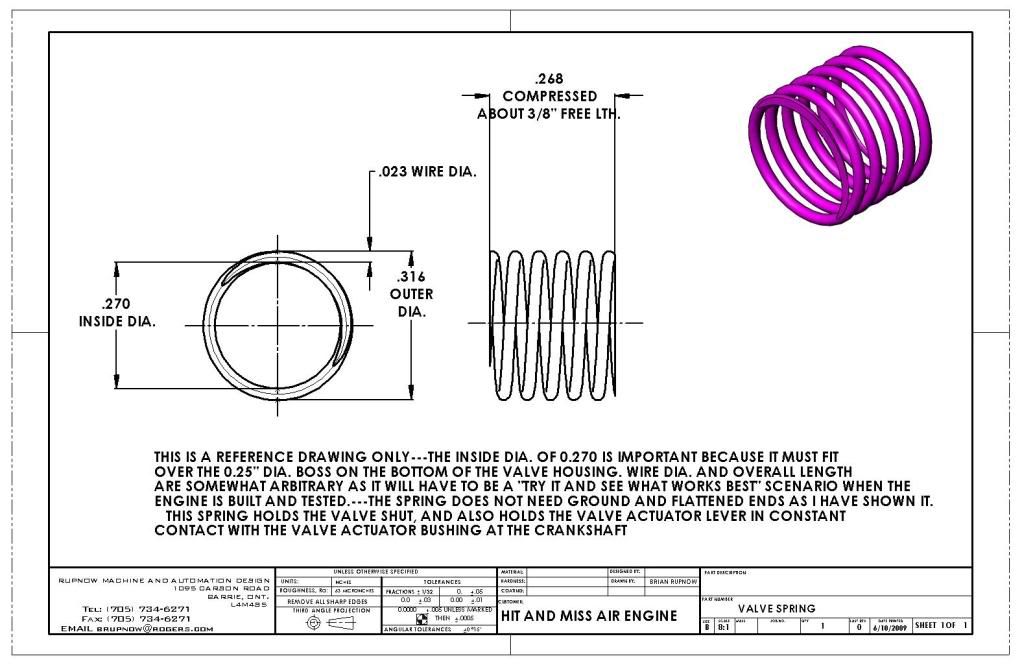

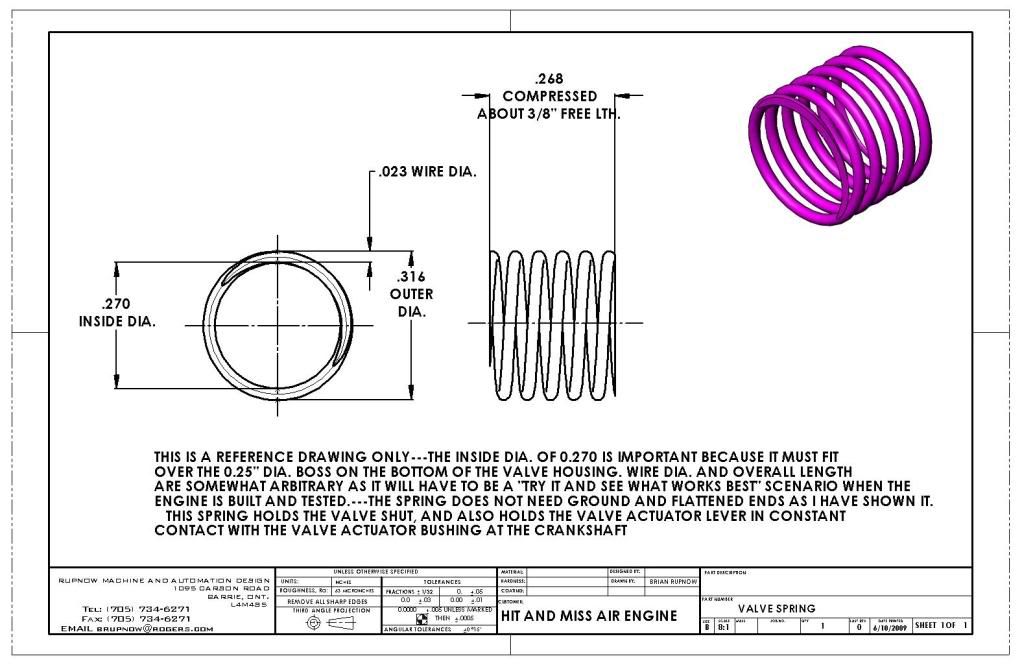

Tel---As I dig deeper into this engine, it appears that there are three distinctly different springs that do different things. (Hey, that rhymes!!) There is a spring in the cylinder head that operates the exhaust valve slug, there is a spring buried in the mechanism of the governor to return the weighted arms to the "parallel to crankshaft" position at low RPM. And a third spring which has the function of #1--keeping the intake valve seated, and also #2 keeping the fork which is activated by the "cam" seated against the rotating collar of the dog clutch.---Right?

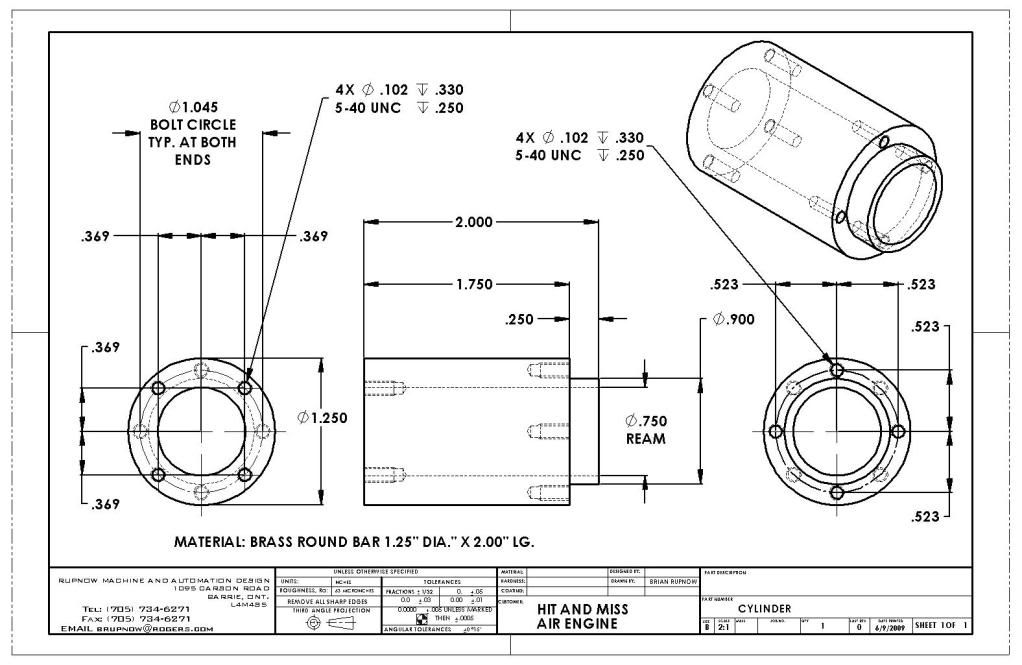

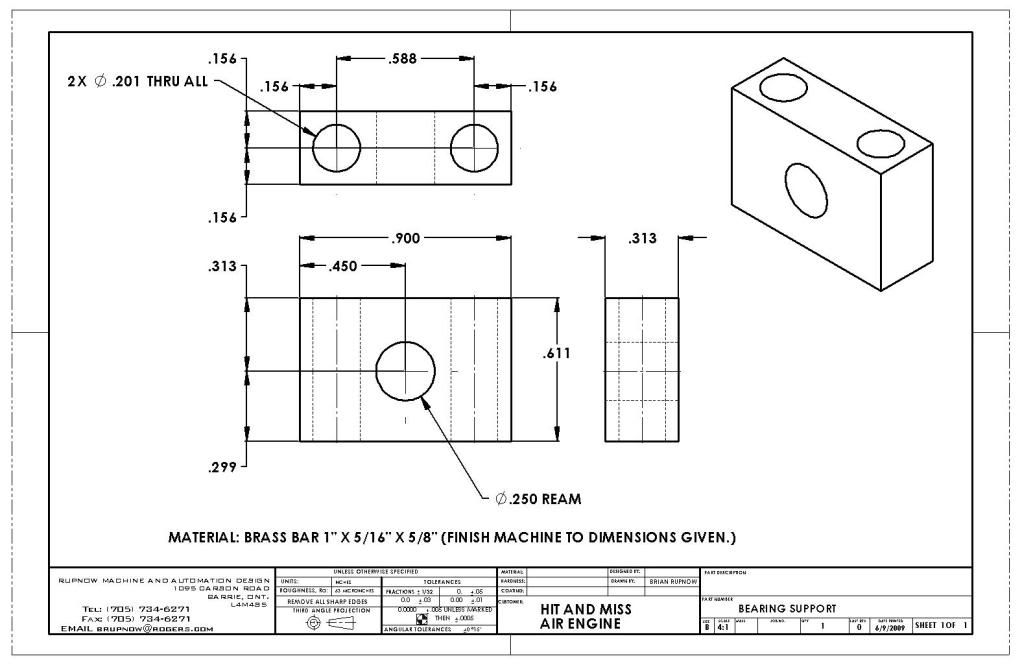

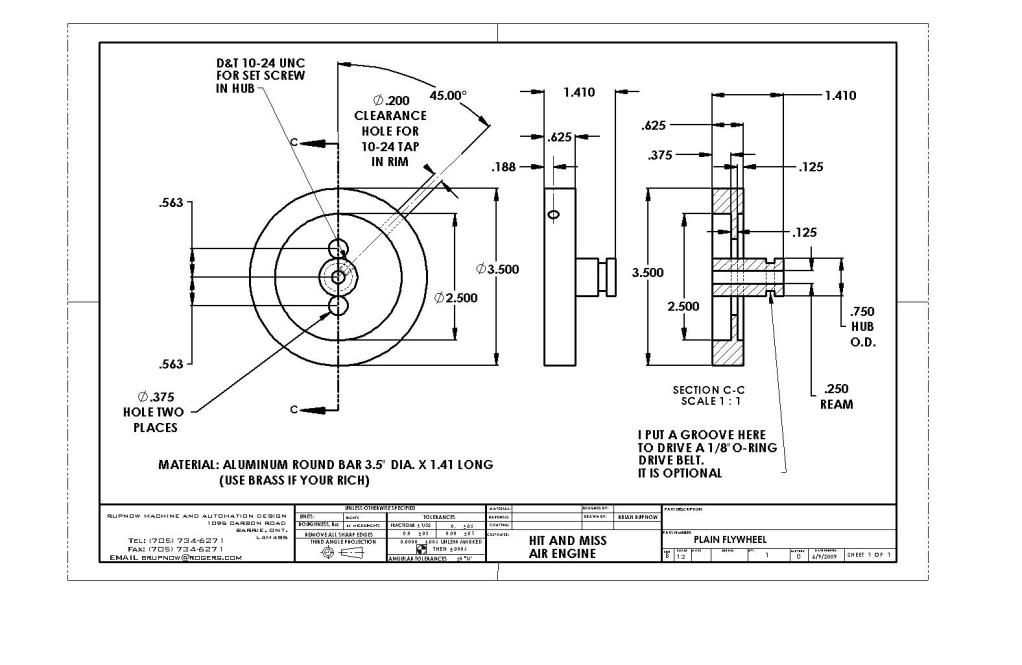

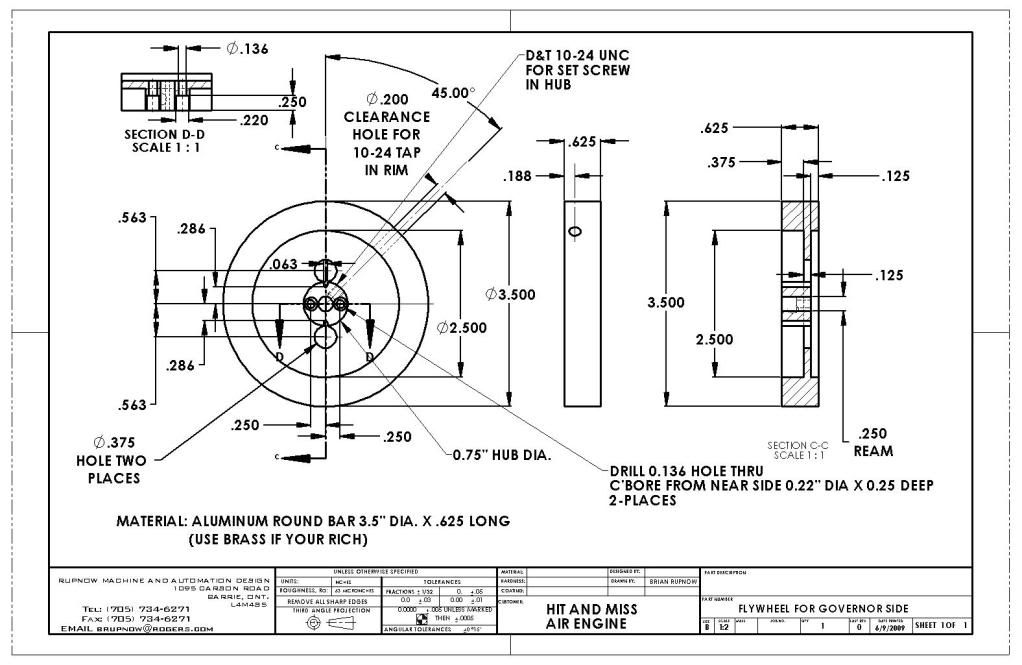

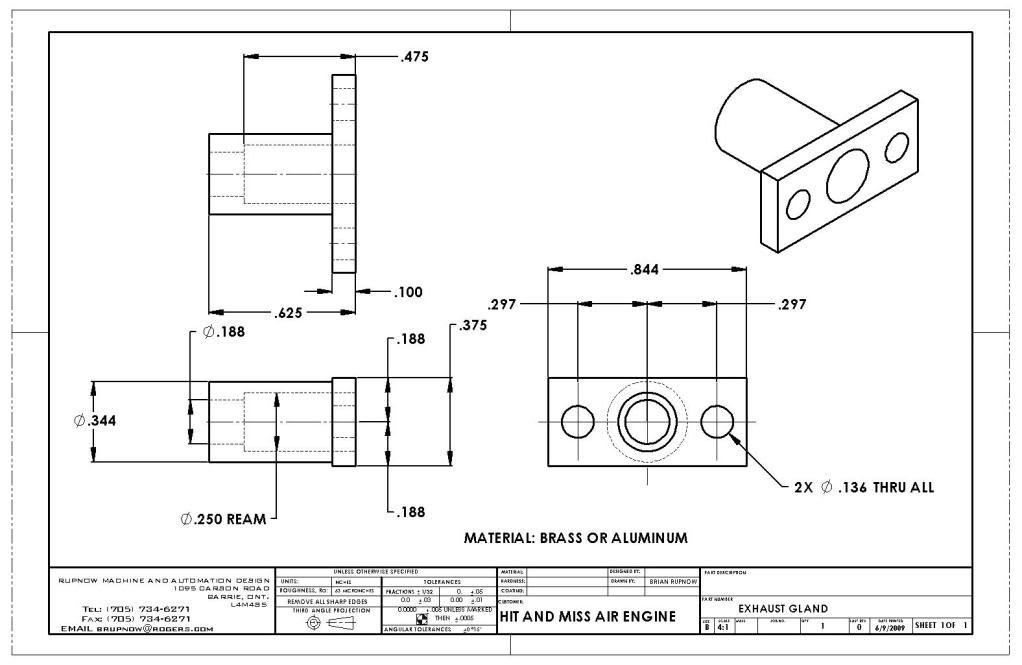

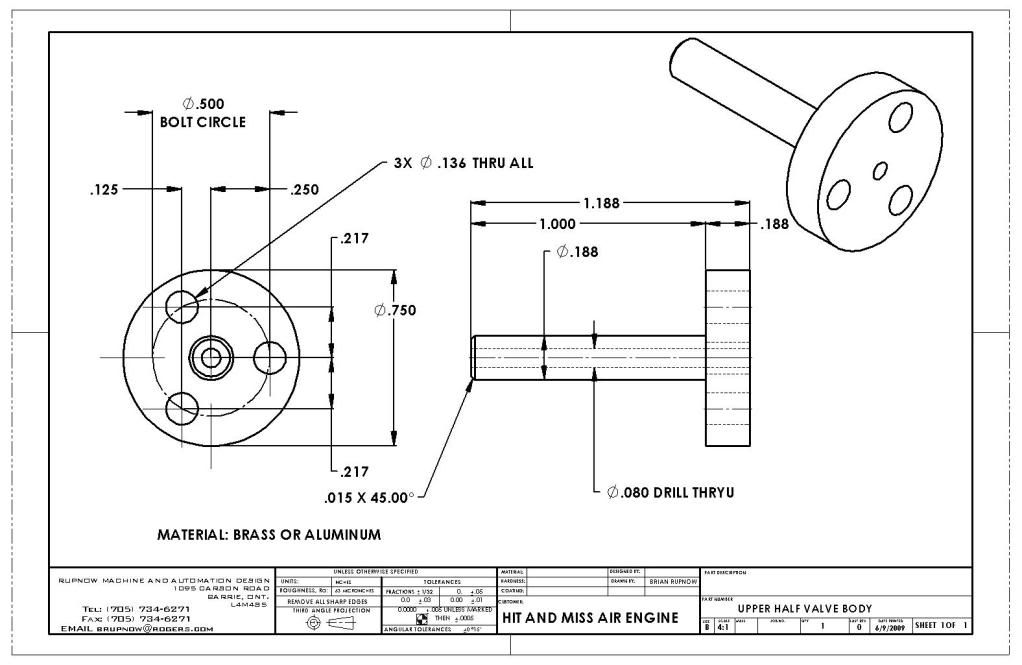

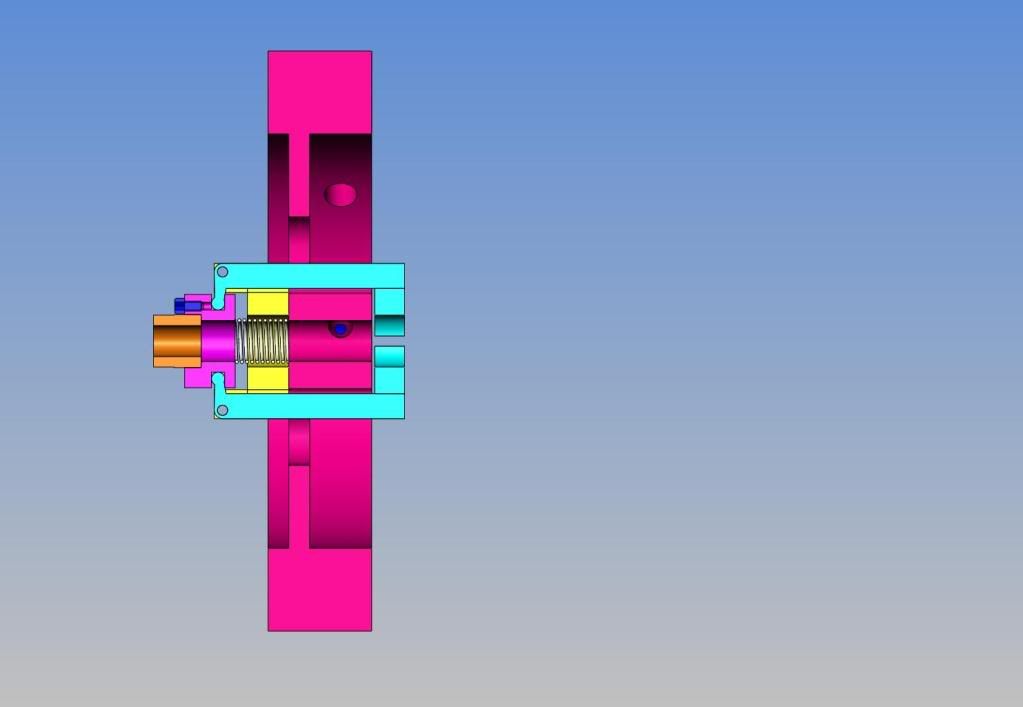

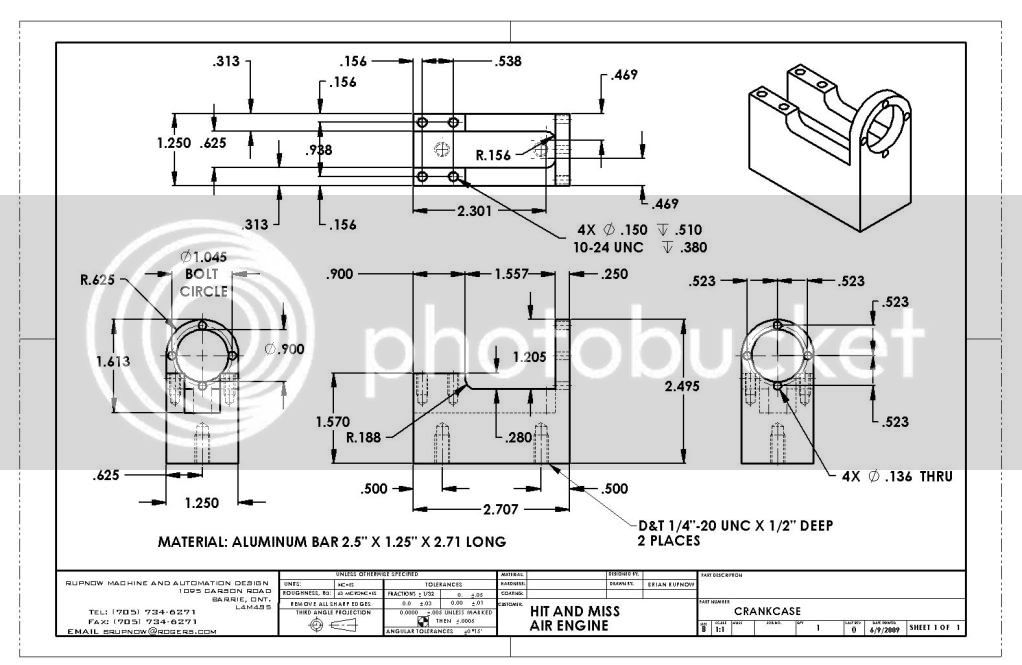

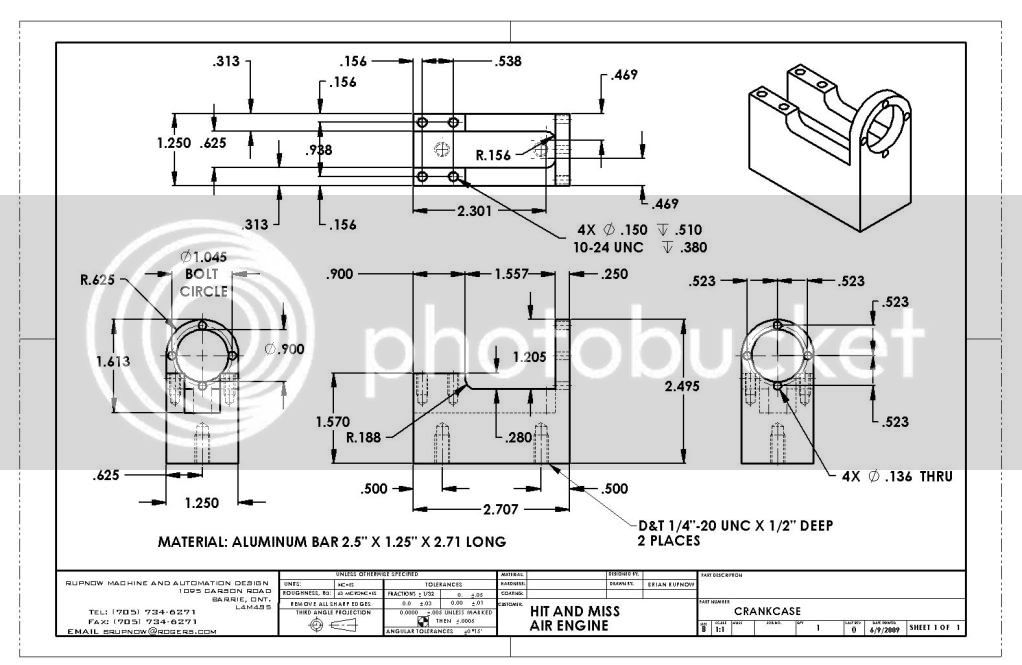

Allright!!! I've worked my way thru this thing with solid models. I may not build it untill fall, but since I have very little engineering work right now, I'm going to go ahead and detail the whole thing. Again, this is not meant to take away from any of the excellent work done by Chuck, superfast. putputman, Brent, nor anyone else that has built this. Its just that this is the way I have to work it out for myself before I can build anything, and if anyone else can benefit from it, then thats a good thing. If you see any mistakes or omissions, let me know and I will fix things and repost the corrected .pdf.---Brian

We will start with the crankcase, made from a solid block of aluminum---

View attachment CRANKCASE.PDF

We will start with the crankcase, made from a solid block of aluminum---

View attachment CRANKCASE.PDF

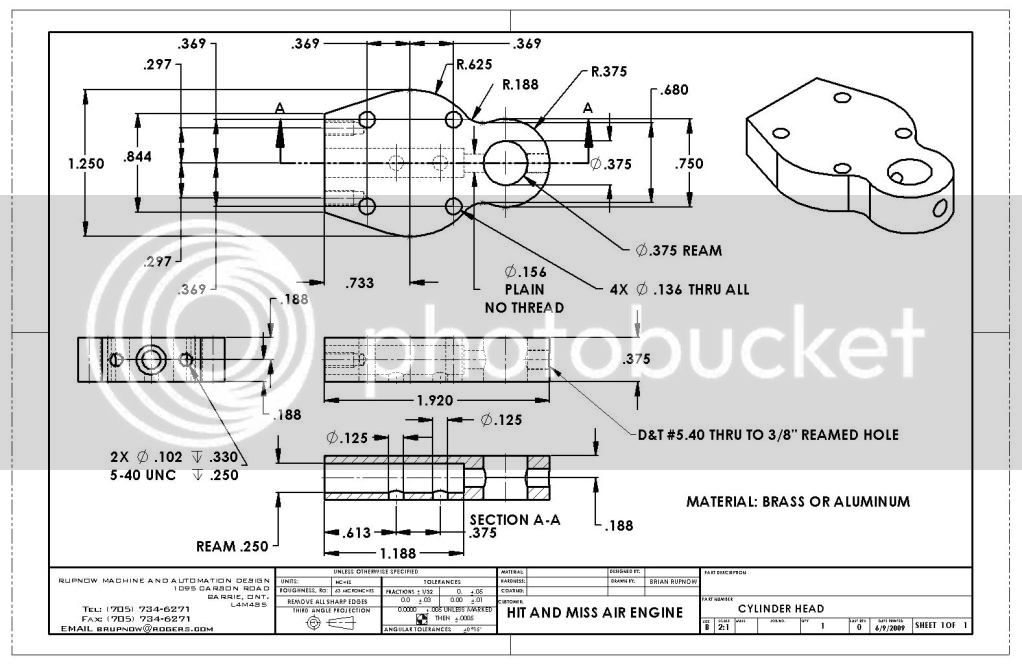

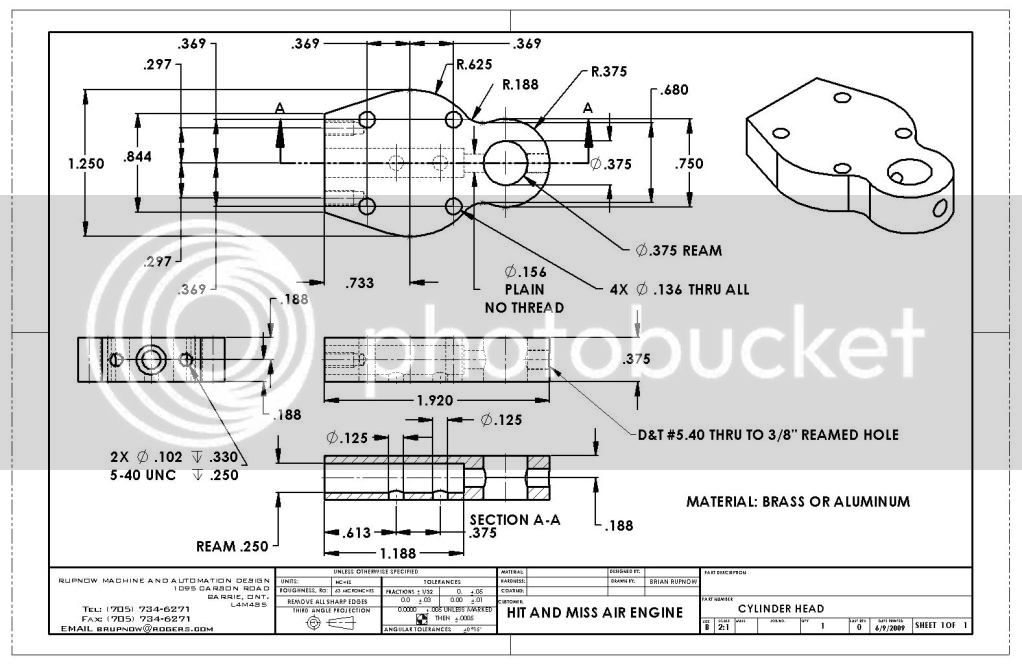

And a cylinder head---

tel

Well-Known Member

- Joined

- Feb 8, 2008

- Messages

- 3,293

- Reaction score

- 44

Tel---As I dig deeper into this engine, it appears that there are three distinctly different springs that do different things. (Hey, that rhymes!!) There is a spring in the cylinder head that operates the exhaust valve slug, there is a spring buried in the mechanism of the governor to return the weighted arms to the "parallel to crankshaft" position at low RPM. And a third spring which has the function of #1--keeping the intake valve seated, and also #2 keeping the fork which is activated by the "cam" seated against the rotating collar of the dog clutch.---Right?

Yep, that's how I see it as well. Plans are coming along nicely mate - another one for my 'future projects' folder

When I get all the details finished I will post a complete file of .pdf's to the download section. I didn't really know that I was going to go this far when I started dabbling with the project last week. ---Thats why it started out in the "break room" section. This is the slowest year I have ever had for engineering work, and there are a 100 hours in every day when I have no work to do. I have been interested in this engine ever since Chuck Fellows built the first one. I looked thru all the threads posted by various builders of this engine, and one thing that struck me was that there was no file that was absolutely complete with details of every part. I do plan on building this engine, and I absolutely MUST have complete plans to work to. So---since I have to do it this way for my own benefit, I might just as well post all the plans for others out there who don't like to build engines "by the seat of their pants".----Brian

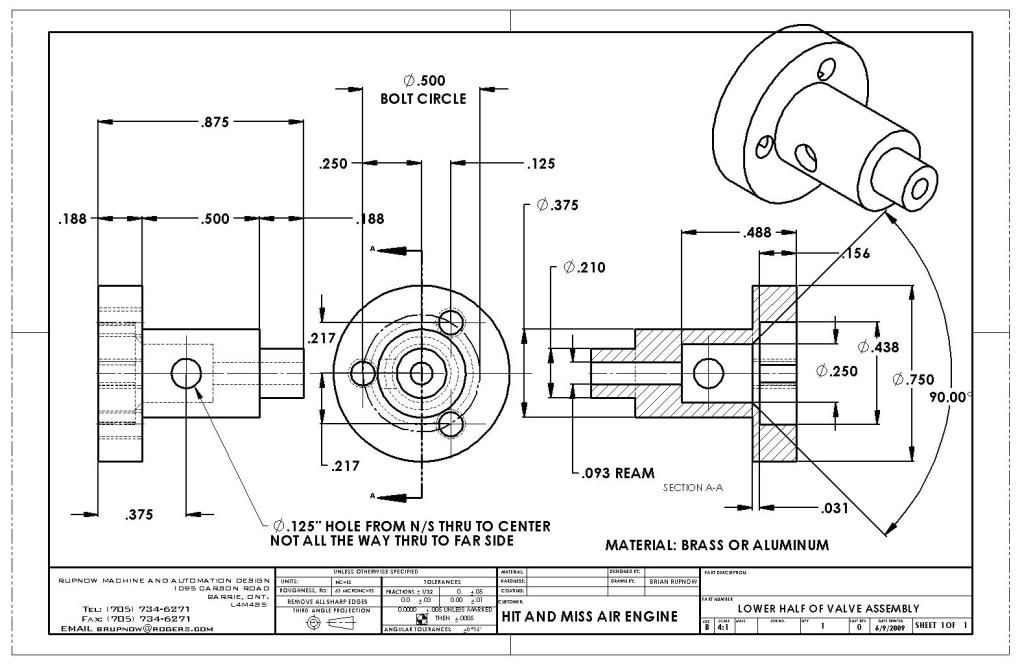

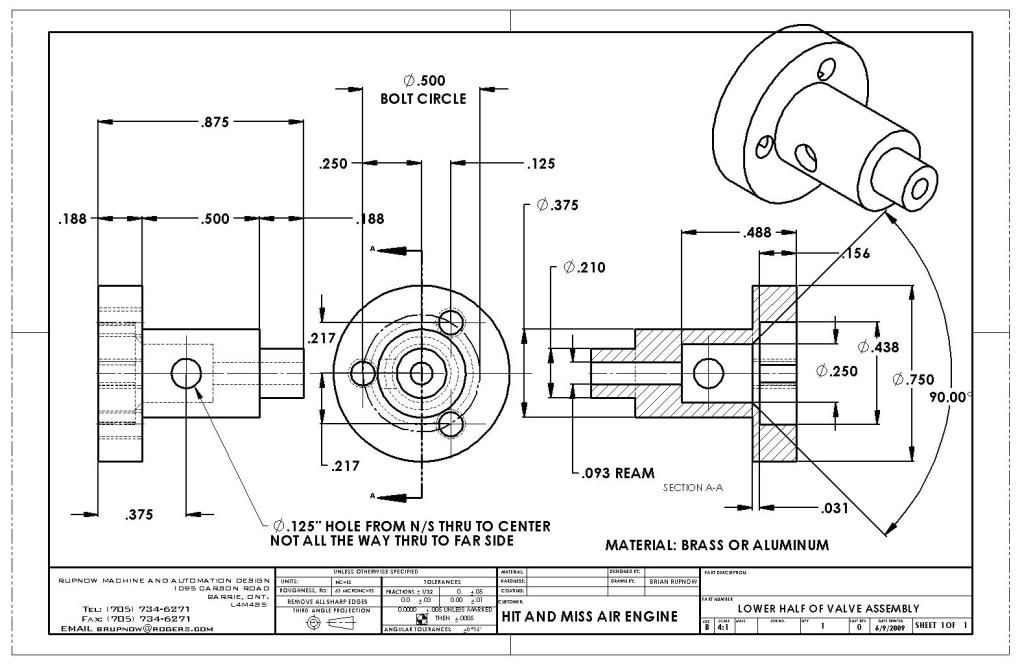

Lower half of valve housing--

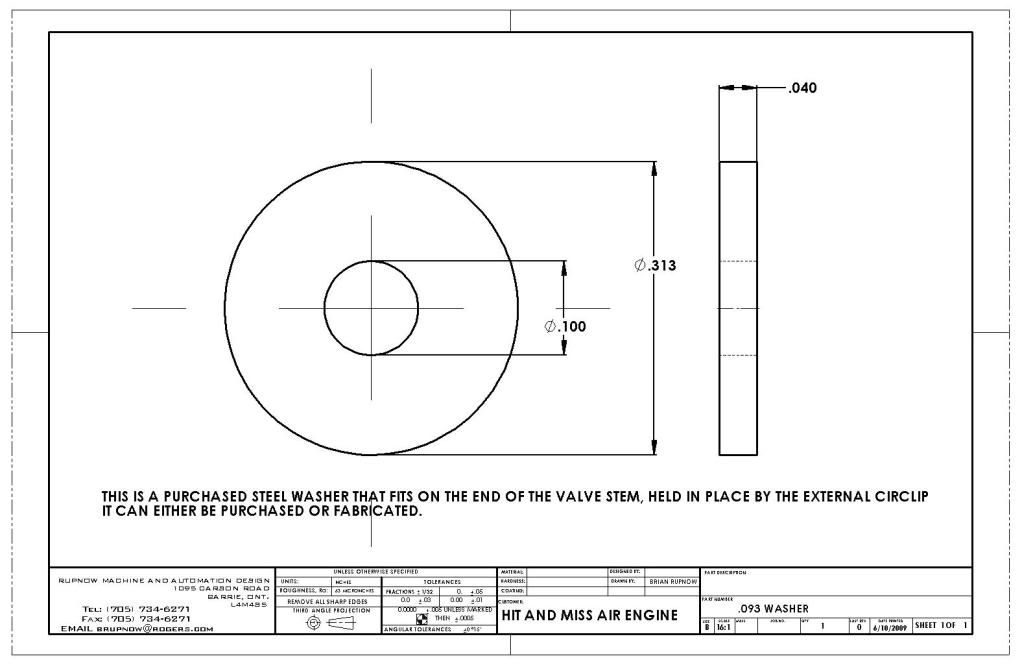

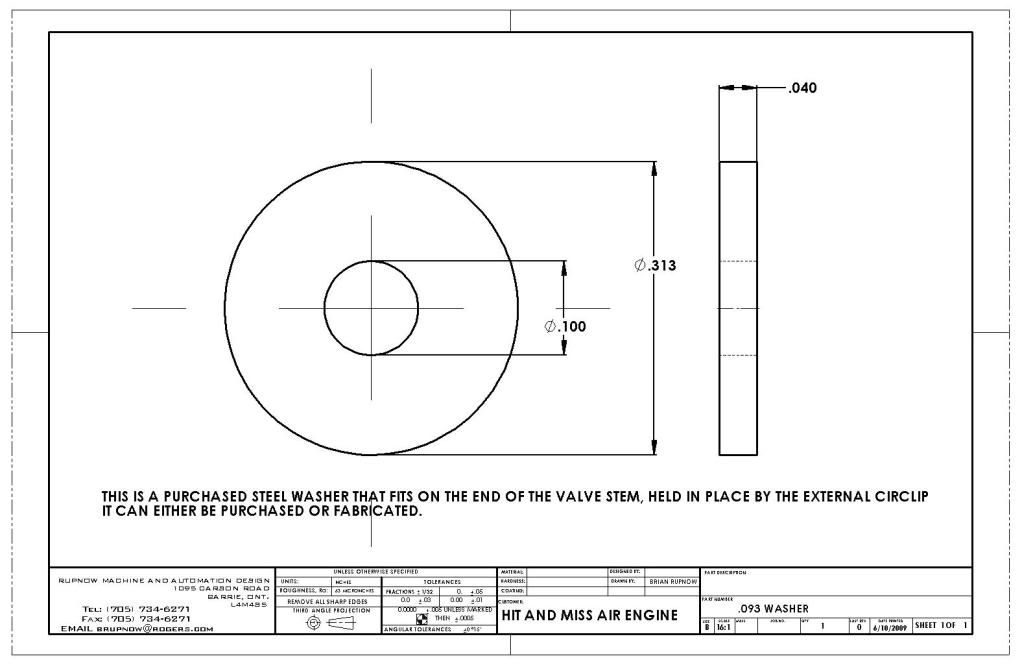

And of course the valve spring and washer--

View attachment .093 WASHER.PDF

View attachment VALVE SPRING.PDF

View attachment .093 WASHER.PDF

View attachment VALVE SPRING.PDF

Similar threads

- Replies

- 19

- Views

- 1K

- Replies

- 1

- Views

- 824

- Replies

- 2

- Views

- 884