B

Bogstandard

Guest

I think I may have asked this before, but my brain has a very short retention rate at the moment, so sorry if I am asking again.

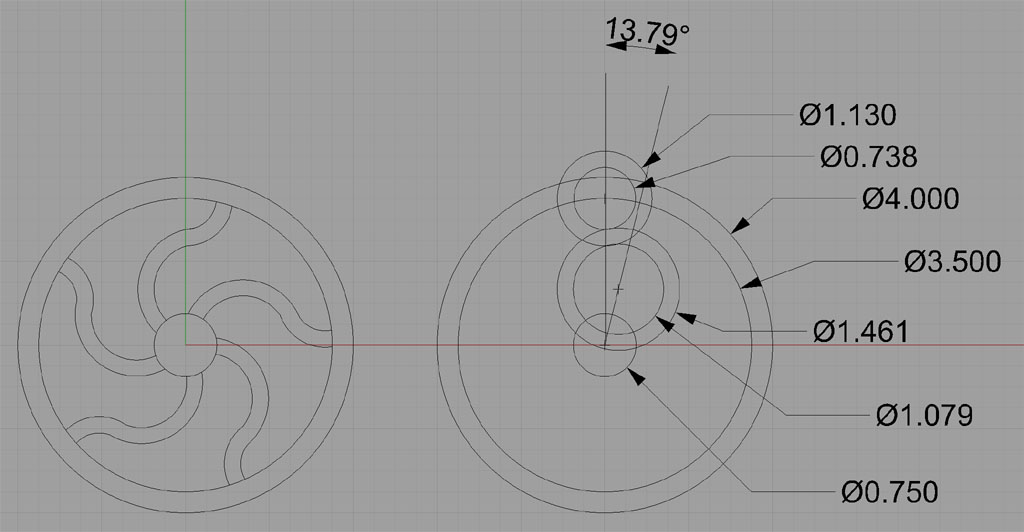

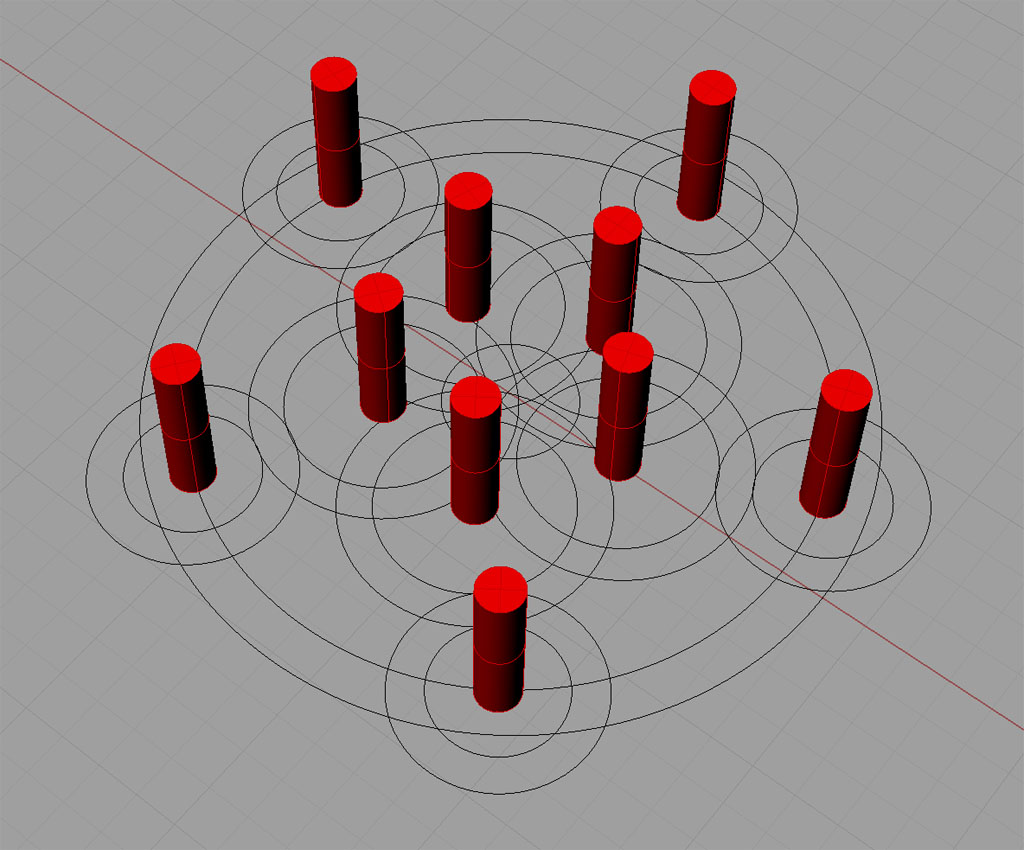

For a forthcoming, rather large project, I am looking for a method to make manually, using the RT, the wiggly spoke type flywheels that Wes has had such great success making using CNC and his own casting techniques.

No insults or ingratitude meant, but please do not point me towards magazine articles, as these are not available in the UK, unless of course you can scan and email.

There must be a method, but even though I am rather experienced in the use of the RT, when it comes to this problem, my mind blanks up.

I don't want to resort to building them up from individual pieces.

Any help would be appreciated.

John

For a forthcoming, rather large project, I am looking for a method to make manually, using the RT, the wiggly spoke type flywheels that Wes has had such great success making using CNC and his own casting techniques.

No insults or ingratitude meant, but please do not point me towards magazine articles, as these are not available in the UK, unless of course you can scan and email.

There must be a method, but even though I am rather experienced in the use of the RT, when it comes to this problem, my mind blanks up.

I don't want to resort to building them up from individual pieces.

Any help would be appreciated.

John