Lamachina58

Well-Known Member

- Joined

- Nov 13, 2010

- Messages

- 74

- Reaction score

- 0

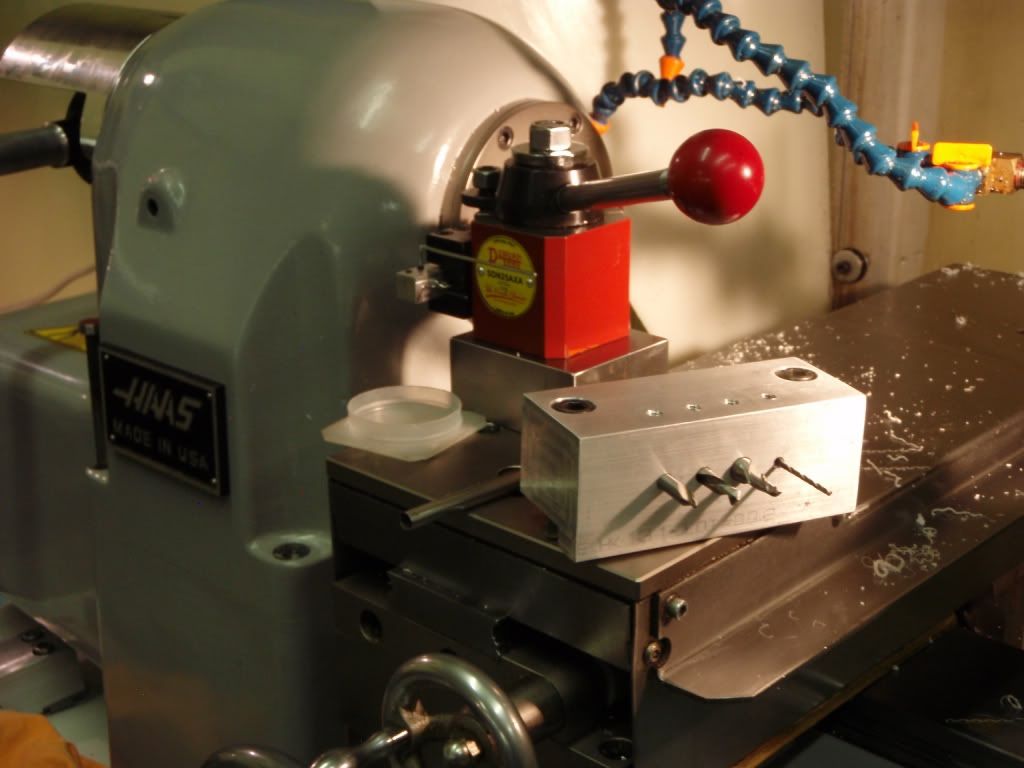

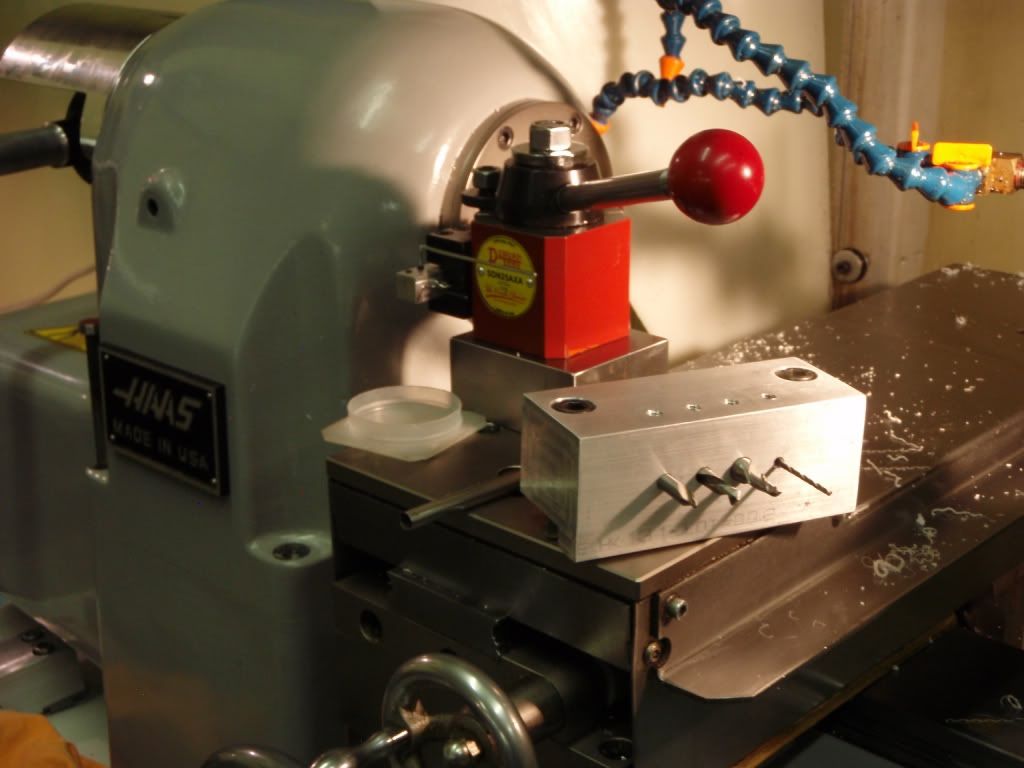

I just discovered this forum and am enjoying it immensely so I thought I'd share a little tool we made and are using today.

Gang tooling is common on CNC machines without a turret. I like to use the gang tools on my lathe, in the toolpost or mounted to the cross slide.

Dorian has an awesome gang tool set up for their larger toolpost but I have the smaller 25AXA. Sam used the lathe to drill the locations spot on.

Recovering from an appendectomy so I am watching my friends make stuff in my shop.

Gang tooling is common on CNC machines without a turret. I like to use the gang tools on my lathe, in the toolpost or mounted to the cross slide.

Dorian has an awesome gang tool set up for their larger toolpost but I have the smaller 25AXA. Sam used the lathe to drill the locations spot on.

Recovering from an appendectomy so I am watching my friends make stuff in my shop.