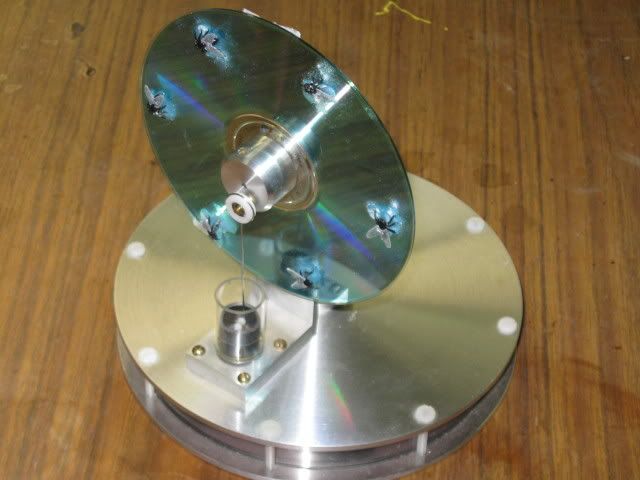

I'm in the process of building one of Jan Ridders LTD Coffee Cup Stirling engines. This engine has certainly been a challenge but I knew it wouldn't be easy before I started it. They are so touchy the slightest increase in friction kills them.

I've currently got the engine to run off the heat of a settop box on top of the TV but haven't been able to achieve running it off the heat of my hand as yet and I'm now looking at ways to further reduce friction.

The engine currently has a 3mm dia (1/8") displacer shaft with a stroke of 12mm (1/2") running through a brass bush however I was wondering since I shouldn't be using oil to help reduce friction if Delrin would produce less friction than the dry brass. I've also considered using graphite as the bush as Jerry Howell does on his Miser which would definately reduce the friction but I'm worried the wear rate of the graphite would be too great.

I've currently got the engine to run off the heat of a settop box on top of the TV but haven't been able to achieve running it off the heat of my hand as yet and I'm now looking at ways to further reduce friction.

The engine currently has a 3mm dia (1/8") displacer shaft with a stroke of 12mm (1/2") running through a brass bush however I was wondering since I shouldn't be using oil to help reduce friction if Delrin would produce less friction than the dry brass. I've also considered using graphite as the bush as Jerry Howell does on his Miser which would definately reduce the friction but I'm worried the wear rate of the graphite would be too great.