John

Active Member

- Joined

- Nov 14, 2007

- Messages

- 38

- Reaction score

- 1

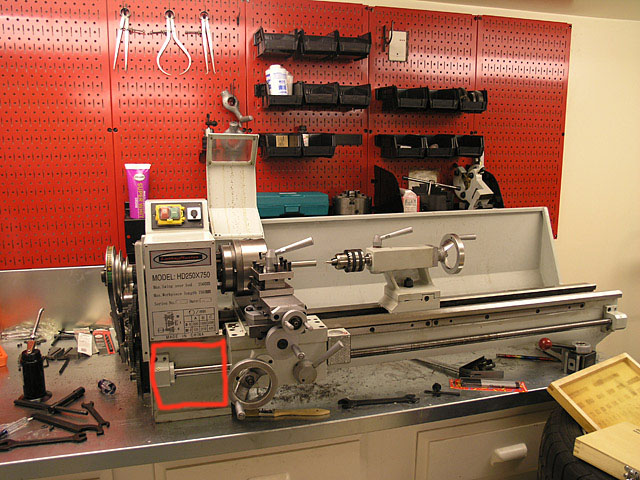

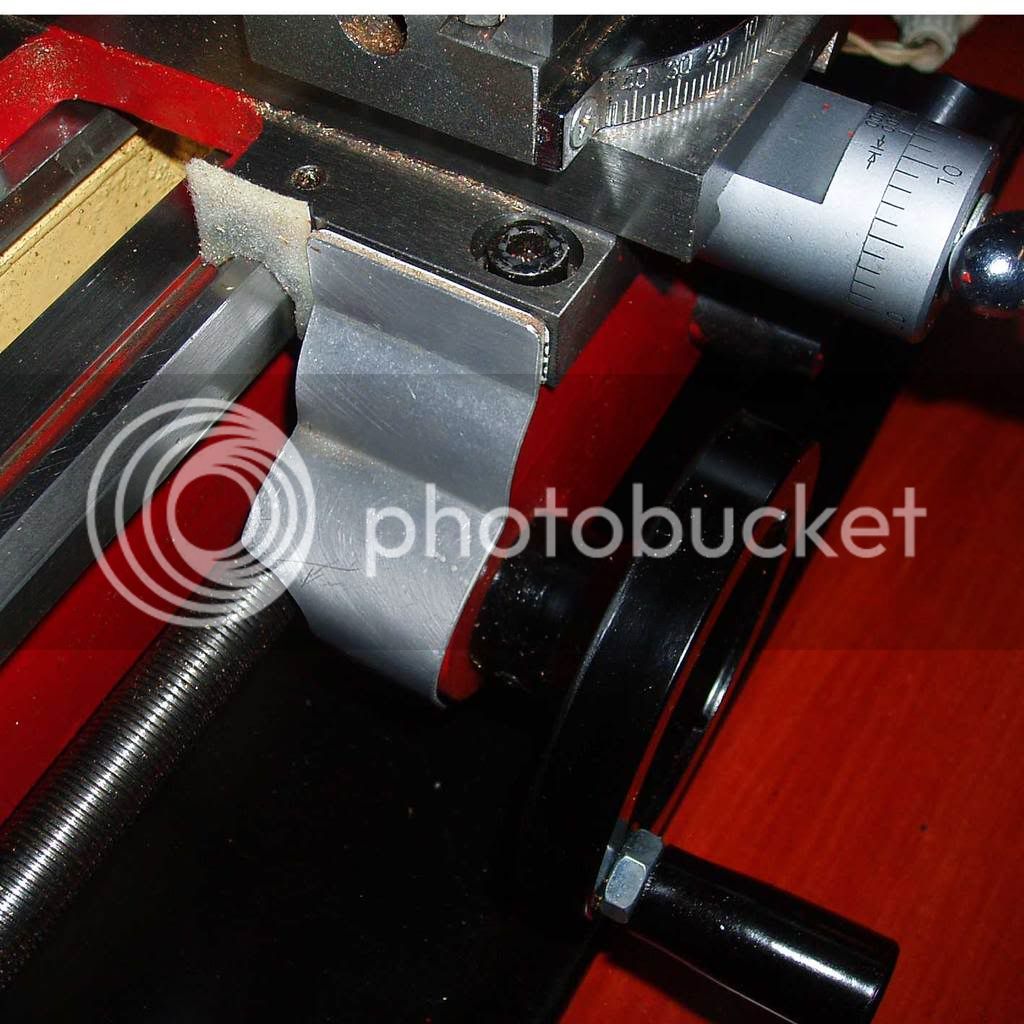

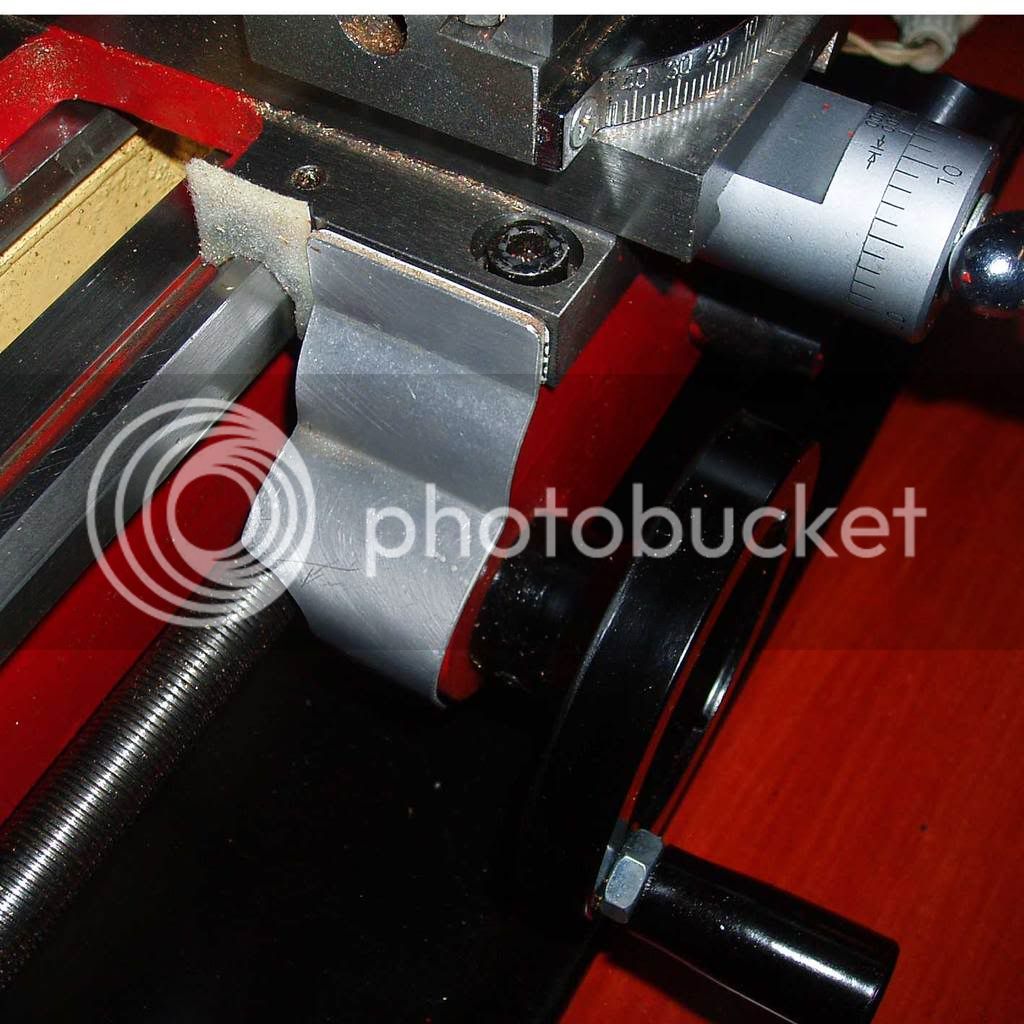

Here are some photographs of some felts I put on the front of the carriage of my lathe to stop chips being trapped between the carriage and the ways. I made these using magnetic rubber cut from fridge magnets - the local real estate agents keep up a supply of these to my mail box along with all the other junk mail.

Just cut out the magnetic rubber to suit the profile of your ways and the glue on some felt material to wipe the ways. The magnetic rubber sticks to the iron of the carriage. Works great.

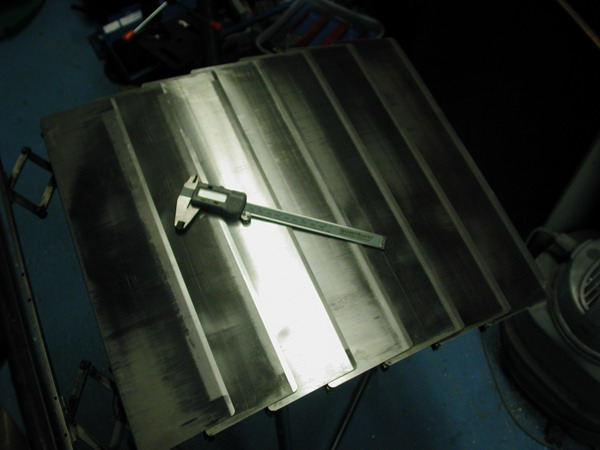

I also had trouble with chips getting into the gears behind the carriage hand wheel. Made up a chip deflector out of thin aluminium sheet and stuck that in place using magnetic rubber . Works well too.

John

Just cut out the magnetic rubber to suit the profile of your ways and the glue on some felt material to wipe the ways. The magnetic rubber sticks to the iron of the carriage. Works great.

I also had trouble with chips getting into the gears behind the carriage hand wheel. Made up a chip deflector out of thin aluminium sheet and stuck that in place using magnetic rubber . Works well too.

John