You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Face Mill

- Thread starter Goldigger

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

SmoggyTurnip

Well-Known Member

- Joined

- Mar 12, 2008

- Messages

- 106

- Reaction score

- 0

milotrain said:These might help

Yep that sure helps. Perfectly clear now. But now I wonder why I would want 45 degree instead of 90 degree. I wouldn't be able to turn to a shoulder. What is the advantage of the 45 degree angle?

Does it really take less HP? The cutting dia of a 45deg facemill is smaller than a 90deg of teh same nominal diameter so it removes less material, for the same amount of material removed you would want a larger 45deg cutter requireing the same HP as the smaller 90deg cutter. Same HP in = same swarf out.

Goldigger, Shars postage at checkout is very high to the UK, e-mail them for a quote. I recently bought a set of broahes, checkout postage was about $150, I got it for $12.95 and the goods arrived in 4 days

Even a 2" 45deg facemill may be too big for teh SX2 as it quotes 30mm max dia for facemilling, a 2" FM will have a cutting dia of about 38mm. Also The facemills linked to from Shars all use the same picture, teh 2" one actually only has 3 inserts so you may as well use the Glanze type indexable endmills you mentioned at the start of this thread.

Goldigger, Shars postage at checkout is very high to the UK, e-mail them for a quote. I recently bought a set of broahes, checkout postage was about $150, I got it for $12.95 and the goods arrived in 4 days

Even a 2" 45deg facemill may be too big for teh SX2 as it quotes 30mm max dia for facemilling, a 2" FM will have a cutting dia of about 38mm. Also The facemills linked to from Shars all use the same picture, teh 2" one actually only has 3 inserts so you may as well use the Glanze type indexable endmills you mentioned at the start of this thread.

I believe it does because the tool's cutting face is technically "ramping" itself into the work. It may calculate out that because technically it's cutting less material that is the majority gain in efficiency but I don't know. Although I guess technically each insert is engaging more material than a 90° would be engaging. Dunno.

Another benefit of the 45°is that those inserts have Four cutting surfaces while the 90° inserts typically only have two, so you get twice the insert life out of a 45°.

Another benefit of the 45°is that those inserts have Four cutting surfaces while the 90° inserts typically only have two, so you get twice the insert life out of a 45°.

Here is KenAmetal's tech tip comparison between the two:

http://www.kennametal.com/images/pd...f;jsessionid=RGSPCISJNBLXRLAUCYPCFEVMCQFBYIV0

Here is what Glacern says:

For general purpose facing and fine finishing, the GMT FM45 nickel-plated cutters are hard to beat. 20-degree positive inserts are held in 19-degree positive inclined pockets for low-vibration cutting. Can be used on smaller machines thanks to the low horsepower requirements.

Chip-thinning from the 45-degree lead angle allows increased feedrates by 50% over 90-degree cutters. Size ANSI SE43 (ISO SE 1204) square inserts maintain chip thinning to a cutting depth of 0.250". The chamfers on the inserts provide a wiper effect to minimize surface roughness.

http://www.kennametal.com/images/pd...f;jsessionid=RGSPCISJNBLXRLAUCYPCFEVMCQFBYIV0

Here is what Glacern says:

For general purpose facing and fine finishing, the GMT FM45 nickel-plated cutters are hard to beat. 20-degree positive inserts are held in 19-degree positive inclined pockets for low-vibration cutting. Can be used on smaller machines thanks to the low horsepower requirements.

Chip-thinning from the 45-degree lead angle allows increased feedrates by 50% over 90-degree cutters. Size ANSI SE43 (ISO SE 1204) square inserts maintain chip thinning to a cutting depth of 0.250". The chamfers on the inserts provide a wiper effect to minimize surface roughness.

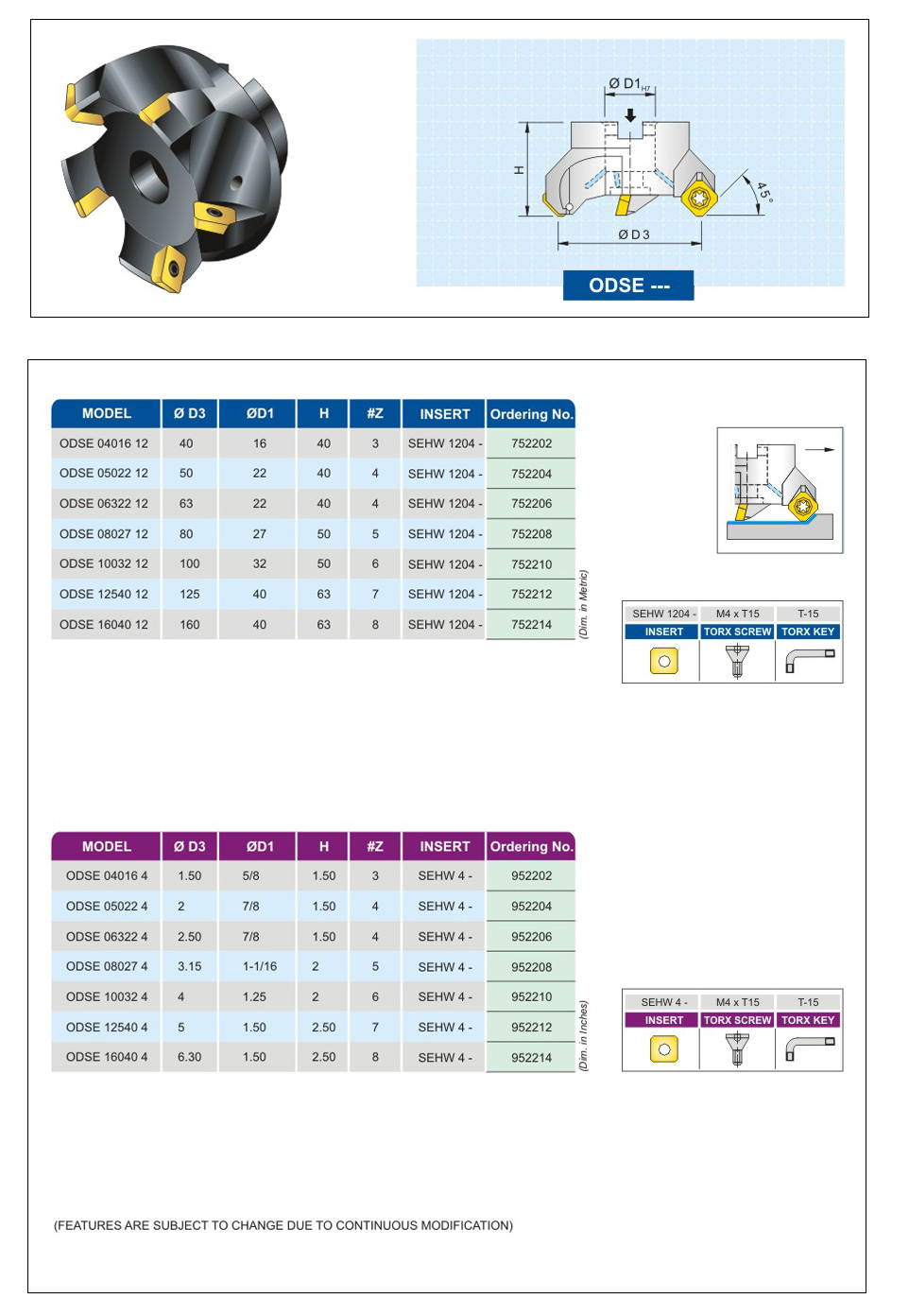

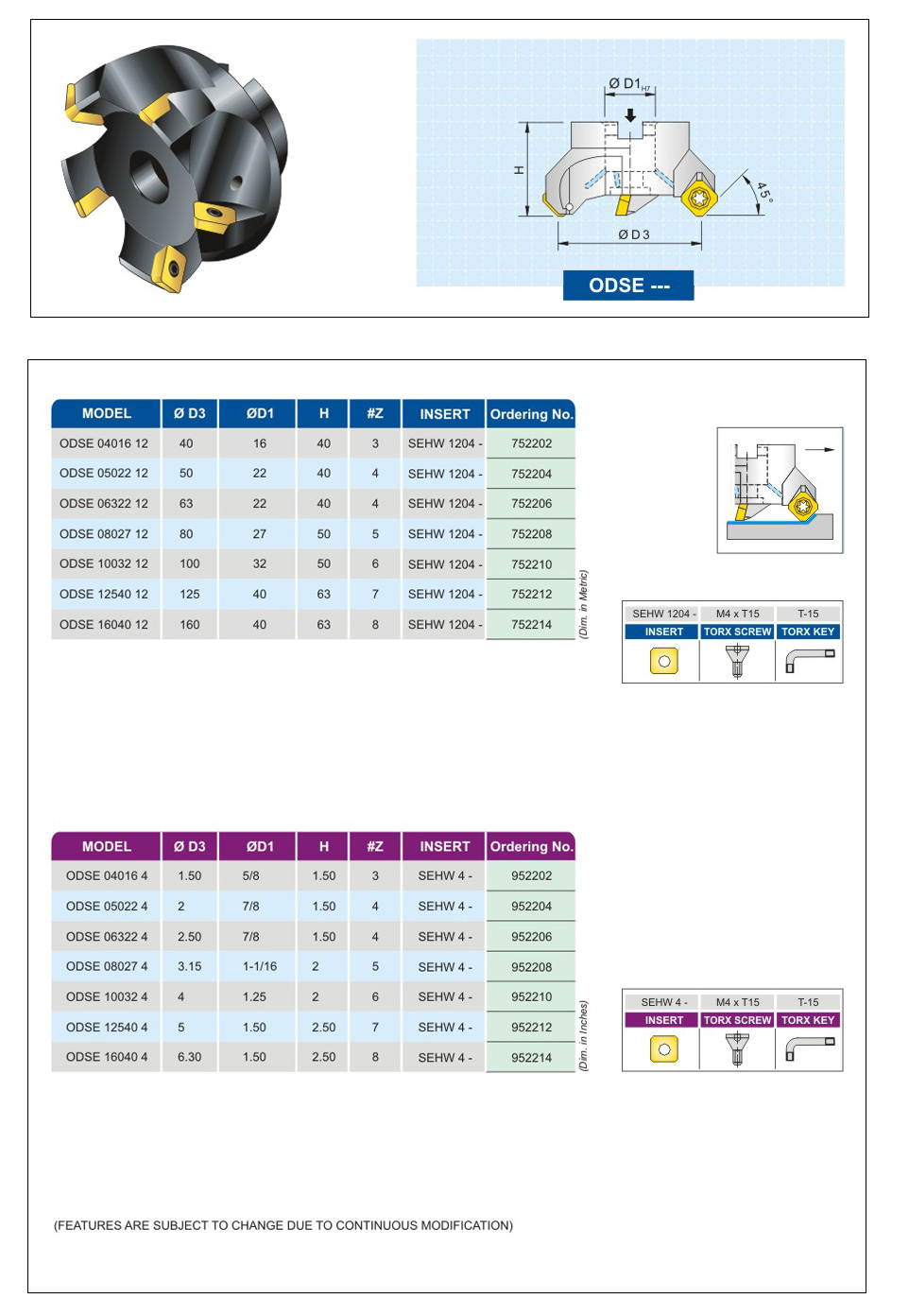

I found that Glanze have 45 degree face mills, just waiting on a price and if they do a MT3 arbour for it..

Through Chronos (uk)

http://www.glanze.com/indexable-tool-holders/cartridges-ofmt-odse.html

Through Chronos (uk)

http://www.glanze.com/indexable-tool-holders/cartridges-ofmt-odse.html

Sshire

Well-Known Member

- Joined

- Jun 29, 2011

- Messages

- 936

- Reaction score

- 259

I was pretty much all set to order the Glacern FM-45 @ $99. It does not have a shank. They do have one (R8-FM45-200) with an integral R8 shank but it is $179.99. That's now on hold til the machining fund fills up again.

- Joined

- Oct 20, 2010

- Messages

- 913

- Reaction score

- 132

Some consideration for you. As that tool does not have the ability to adjust the cutting bits. A tool with the intergral shank might well be a better choice.

Consider this intergral shank: shaft with taper axis, at 90° to cutting pockets plane.

Composit Shank: Shaft with taper, with flange 90° to axis, shaft extension parallel axis, Diameter close to bore size, Bore in tool fit to shaft, and 90° to cutting pockets, Flange face parallel to cutting pocket Plane.

If the same machines make each tool, same machinist as well which tool would be the best as an "only tool". Where I mean this is your only xD face mill. As the milled surface finish is a direct result of the runout of the tool, all other conditions being equal.

I have a 3" intergral shank 5 insert cutter bit, chinese face mill, VERY good surface finish, I have a 6" monster with 15 adjustable inserts thats only a little bit better.

Consider this intergral shank: shaft with taper axis, at 90° to cutting pockets plane.

Composit Shank: Shaft with taper, with flange 90° to axis, shaft extension parallel axis, Diameter close to bore size, Bore in tool fit to shaft, and 90° to cutting pockets, Flange face parallel to cutting pocket Plane.

If the same machines make each tool, same machinist as well which tool would be the best as an "only tool". Where I mean this is your only xD face mill. As the milled surface finish is a direct result of the runout of the tool, all other conditions being equal.

I have a 3" intergral shank 5 insert cutter bit, chinese face mill, VERY good surface finish, I have a 6" monster with 15 adjustable inserts thats only a little bit better.

I was just browsing through eBay and came across ctc tools..anybody have any experience with their tools?

Found this facemill which looks interesting..any opinions?

http://www.ebay.co.uk/itm/50-MM-IND...3?pt=BI_Tool_Work_Holding&hash=item2314c78c63

http://www.ebay.co.uk/itm/BRAND-NEW...314?pt=LH_DefaultDomain_3&hash=item231575f10a

Cheers

Found this facemill which looks interesting..any opinions?

http://www.ebay.co.uk/itm/50-MM-IND...3?pt=BI_Tool_Work_Holding&hash=item2314c78c63

http://www.ebay.co.uk/itm/BRAND-NEW...314?pt=LH_DefaultDomain_3&hash=item231575f10a

Cheers

same store as http://www.ctctools.biz/servlet/StoreFront ??

If answer is yes, I've bought stuff from them on several occasions, with no regrets.

Marcello

If answer is yes, I've bought stuff from them on several occasions, with no regrets.

Marcello

ShedBoy

Senior Member

- Joined

- May 13, 2011

- Messages

- 792

- Reaction score

- 34

I have spent money with this company numerous times. Bought a set of ER32 collets for the price I could get two locally. ER32 to 5c collet holder wich has a total runout of 0.0001 that was advertised at 0.0005. Just got a set of of end mills and also a set of ball nose mills for a more than reasonable price. Big thumbs up from me. There is also a company called YSS Tools who are a good bunch also. Oh also got a full set of mod 1 cutters for $80 to my door. No regrets at all and fast delivery.

Brock

Brock

I've bought from CTC several times and have never been disappointed, and as a bonus their stuff comes in the cutest little parcels.

http://bbs.homeshopmachinist.net/showthread.php?t=50810

An update on the cutter I mentioned back in June in post 25. I've given that cutter a lot of work since then, it gets all the crappy jobs, it gets to clean up the mystery metal that is pitted, painted, rusty, welded, oxy cut, the inserts are tough little beggars whatever they are made from.

http://bbs.homeshopmachinist.net/showthread.php?t=50810

An update on the cutter I mentioned back in June in post 25. I've given that cutter a lot of work since then, it gets all the crappy jobs, it gets to clean up the mystery metal that is pitted, painted, rusty, welded, oxy cut, the inserts are tough little beggars whatever they are made from.