Bob

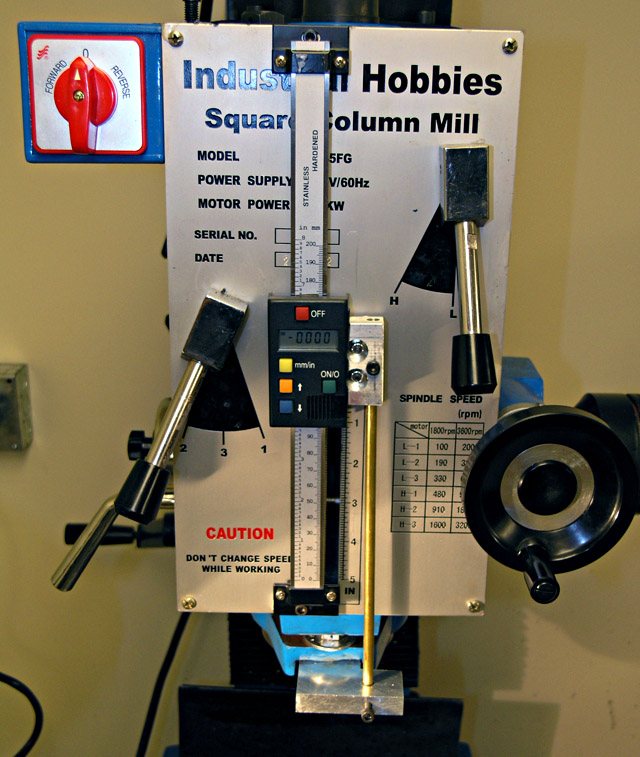

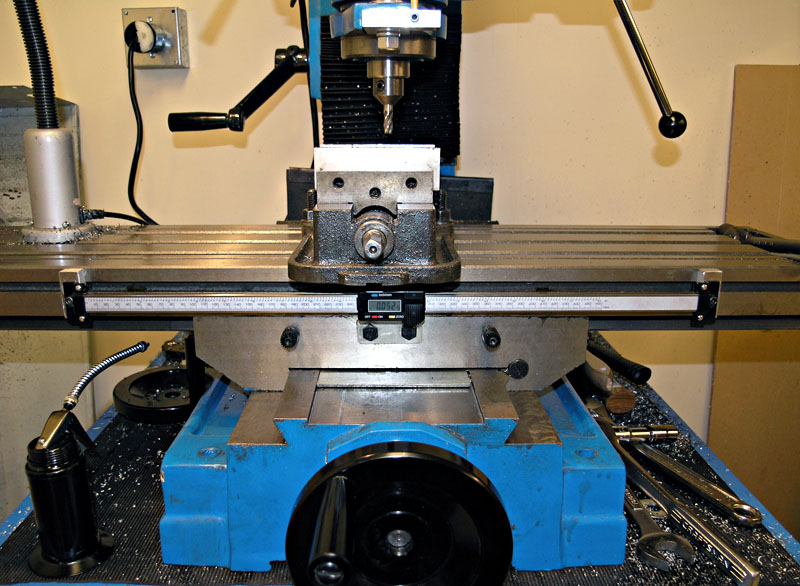

I bought the DRO as a full kit, instead of using caliper scales. I had been told there might be compatibility issues with using caliper scales with the display. I'm pleased to say that the Harbor freight calipers and the inexpensive scales both work just fine and have not been an issue. Even though they take a bit of modification, they've proven to be darned near indestructable. I've cut tines off using a dremel cut off and I've shortened the scales as well as silver soldering on a stub to lengthen one. I used the little depth rod for alignment and all went well. Did I mention they are dirt cheap?

You can buy the DRO display I'm using for a quite reasonable price. The 2 axis display is $149.95 and the 3 axis is $189.95. If you buy the whole kit with scales and mounts it's $349.95, which is what I paid for not knowing that other scales would work so well. The guy I bought from is selling them on ebay at

http://stores.ebay.com/SMW-Precision-LLC_Digital-Displays_W0QQcolZ2QQdirZ1QQfsubZ7QQftidZ2QQtZkm and is a heck of a nice guy who has never had a problem with my calling with questions.

I also noticed 800Watt has some dirt cheap prices for these scales, complete with data output ports. I'm about to order a 16 inch or perhaps a 24 inch scale for when I rework the placement of the scales on my lathe. Note that some of the fancy looking stainless calipers he's selling do not have data ports, so they are not a good choice.

One tip....

Order the 3 axis display and some extra data cords with a bit of added length. I color coded the jacks where the cords plug into the display and then ran cords from my mill and my lathe to it. After color coding each cord, it's easy to simply swap the cords in the jacks so that one display works with both machines. Since I only run them one at a time, it's never any problem. I can even use the Z axis display with my tailstock scale if I like.

You'll love having DROs and the display will moer than double the fun and your accuracy will certainly improve once your old eyes can see whats happening again.

Steve

:

: ??? Now I need to figure out how to mount them. ???

??? Now I need to figure out how to mount them. ???