digiex-chris

Well-Known Member

- Joined

- Dec 6, 2010

- Messages

- 263

- Reaction score

- 58

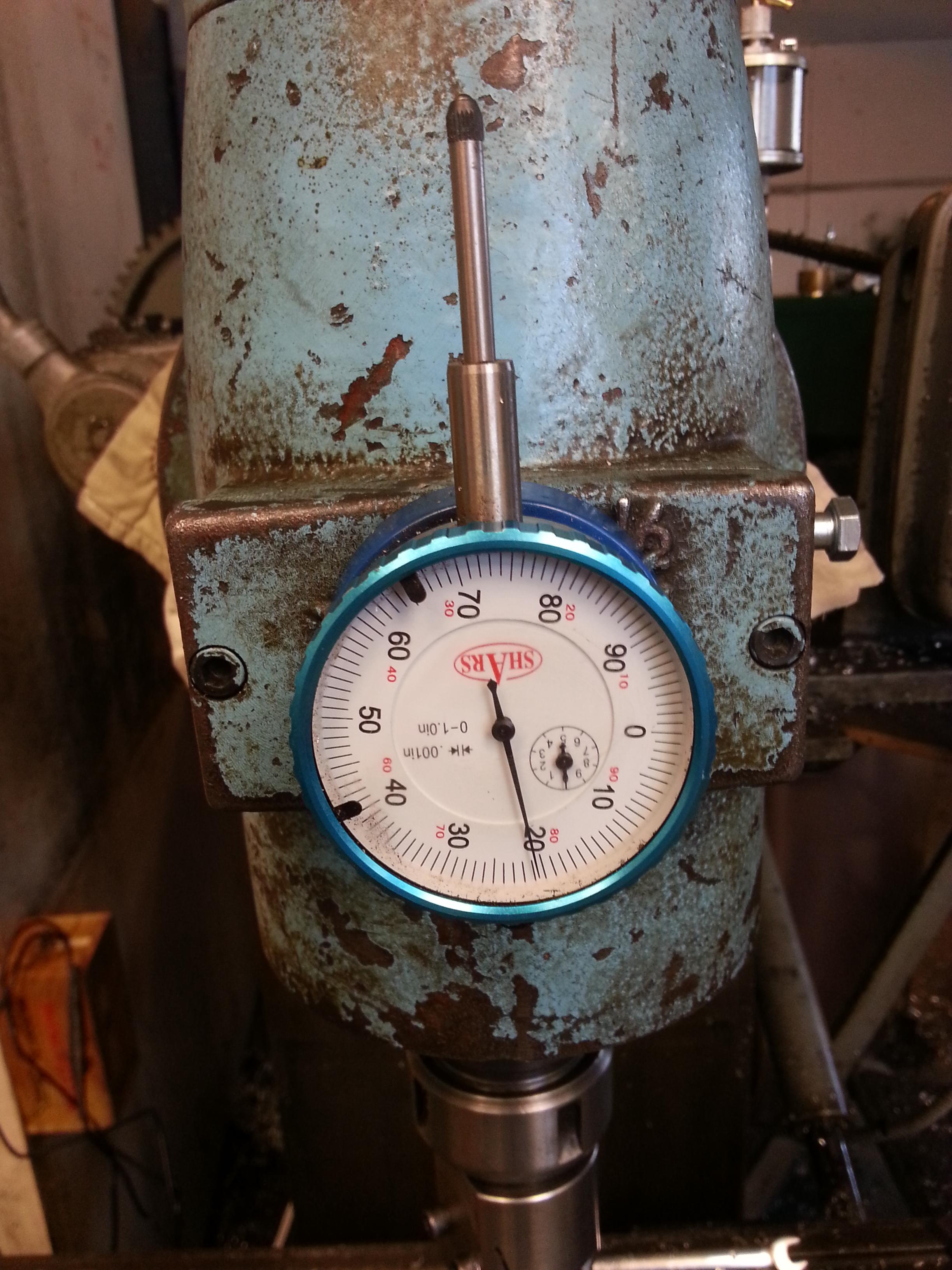

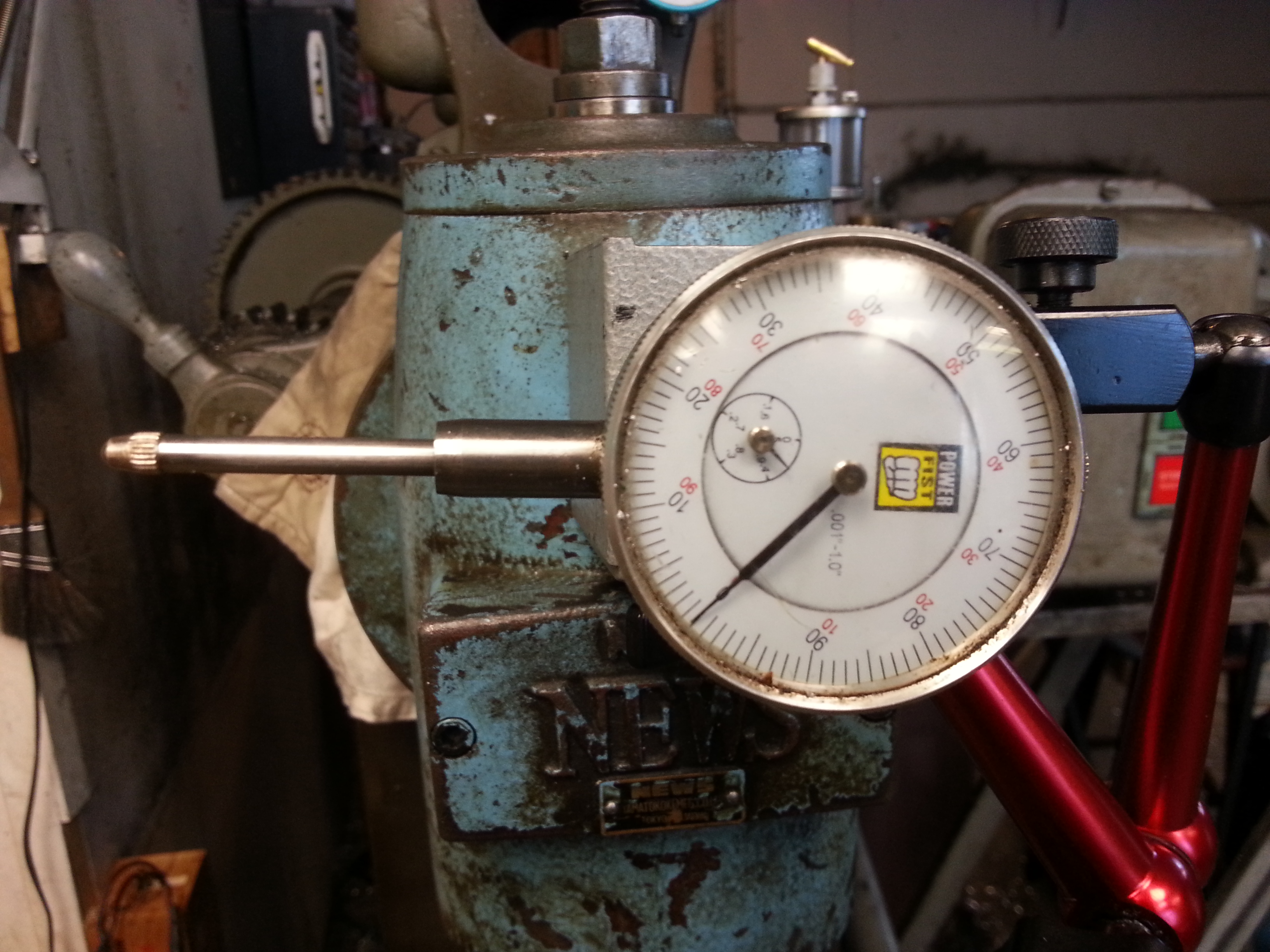

I learned something important about dial indicators this weekend while dialing in a horizontal bore on my horizontal mill.

http://www.longislandindicator.com/p139.html

"We had a belligerent customer whose dial indicator wasn't returning to zero when he used it upside down. We told him that dial indicators are designed to be used right side up. He said "Bull****," which put us on the defensive. We called one of the major US manufacturers, the one located in Athol, Mass., and asked them. They said, indeed, the dial indicator has to be used right side up, that "gravity is a factor in the equation." If the indicator has to be used inverted, then a much stronger return spring has to be installed.

The literature that comes with the brand new digital indicators from Japan's leading manufacturer states plainly and clearly that their state-of-the-art indicator will work anywhere between upright and horizontal. It says nothing about working between horizontal and upside down. Now we feel vindicated, and that complaining customer can eat his words."

In other words, they work fine vertically and horizontally, but not plunger-up. Probably a compromise so they don't have to manufacture to watch standards for a position 99.5% of people never use.

http://www.longislandindicator.com/p139.html

"We had a belligerent customer whose dial indicator wasn't returning to zero when he used it upside down. We told him that dial indicators are designed to be used right side up. He said "Bull****," which put us on the defensive. We called one of the major US manufacturers, the one located in Athol, Mass., and asked them. They said, indeed, the dial indicator has to be used right side up, that "gravity is a factor in the equation." If the indicator has to be used inverted, then a much stronger return spring has to be installed.

The literature that comes with the brand new digital indicators from Japan's leading manufacturer states plainly and clearly that their state-of-the-art indicator will work anywhere between upright and horizontal. It says nothing about working between horizontal and upside down. Now we feel vindicated, and that complaining customer can eat his words."

In other words, they work fine vertically and horizontally, but not plunger-up. Probably a compromise so they don't have to manufacture to watch standards for a position 99.5% of people never use.

Last edited: