toolznthings

Project of the Month Winner

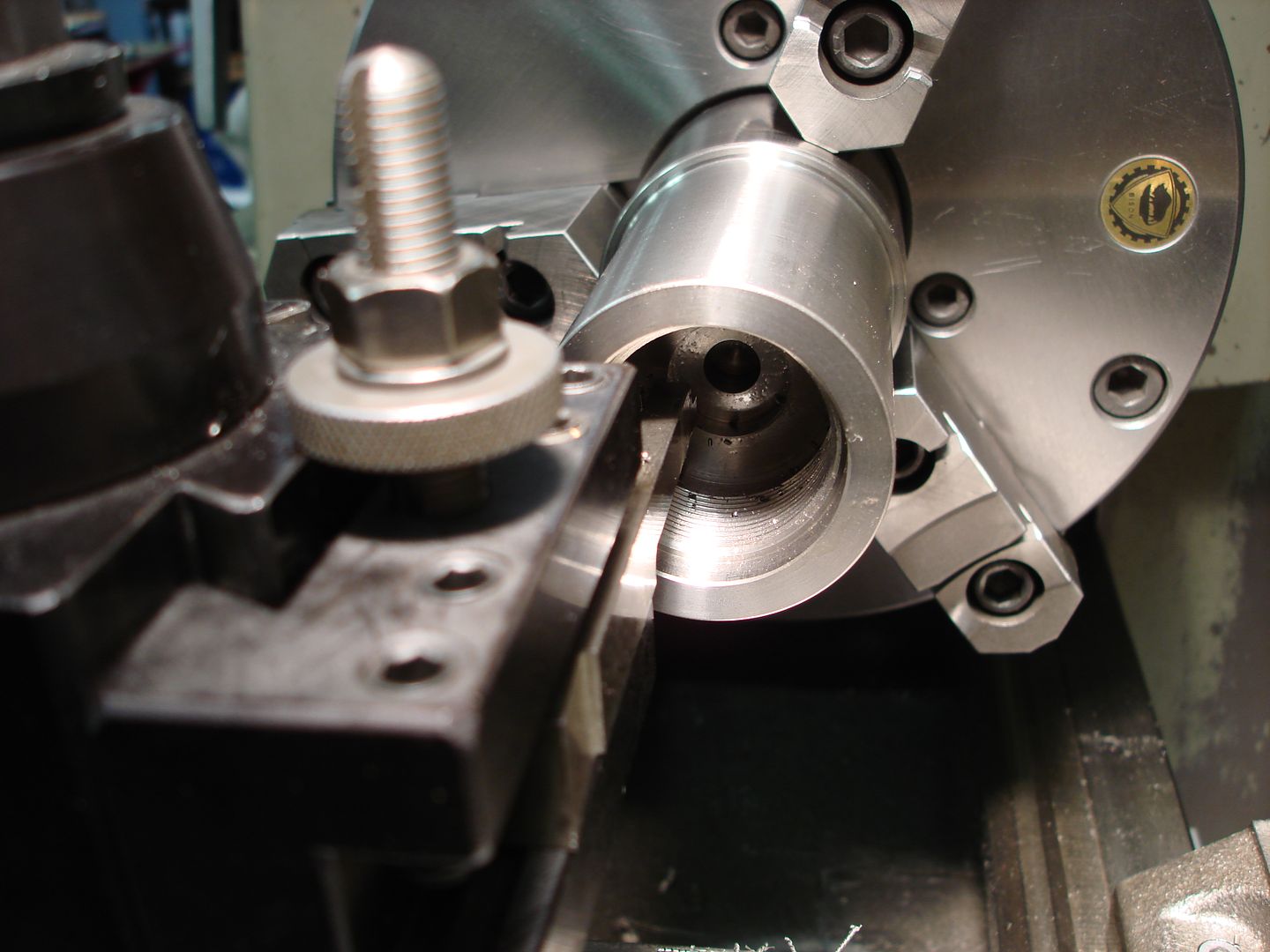

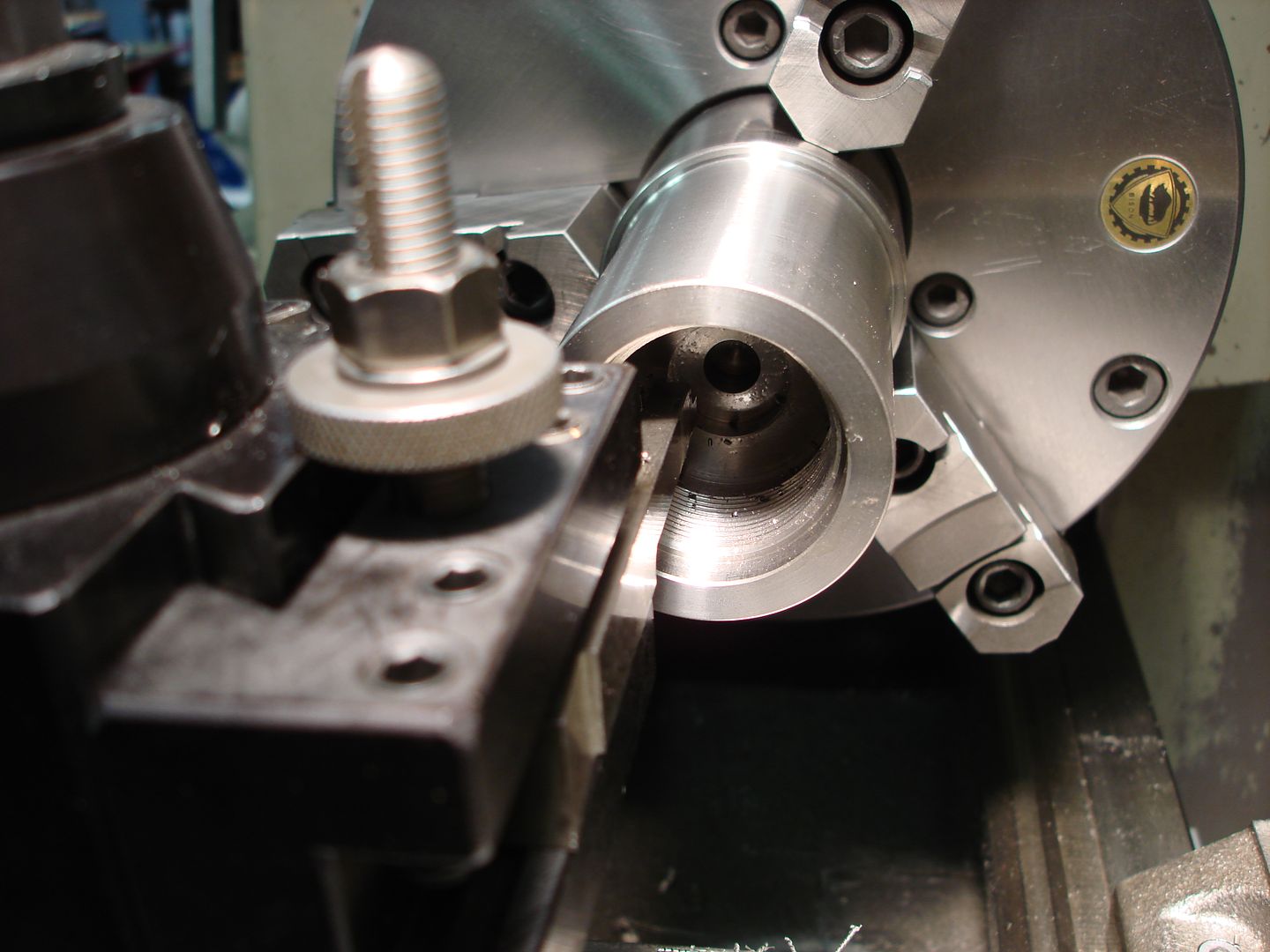

Nothing like chasing I.D. threads on the lathe into a blind end bore.  Especially where the bore is either small or larger, but deep into the parts. Here, I'm chasing a 1 3/8-16 thread into a blind bore about 1 1/4" deep. There is a thread undercut to run the thread into, but at the bottom of the bore.

Especially where the bore is either small or larger, but deep into the parts. Here, I'm chasing a 1 3/8-16 thread into a blind bore about 1 1/4" deep. There is a thread undercut to run the thread into, but at the bottom of the bore.

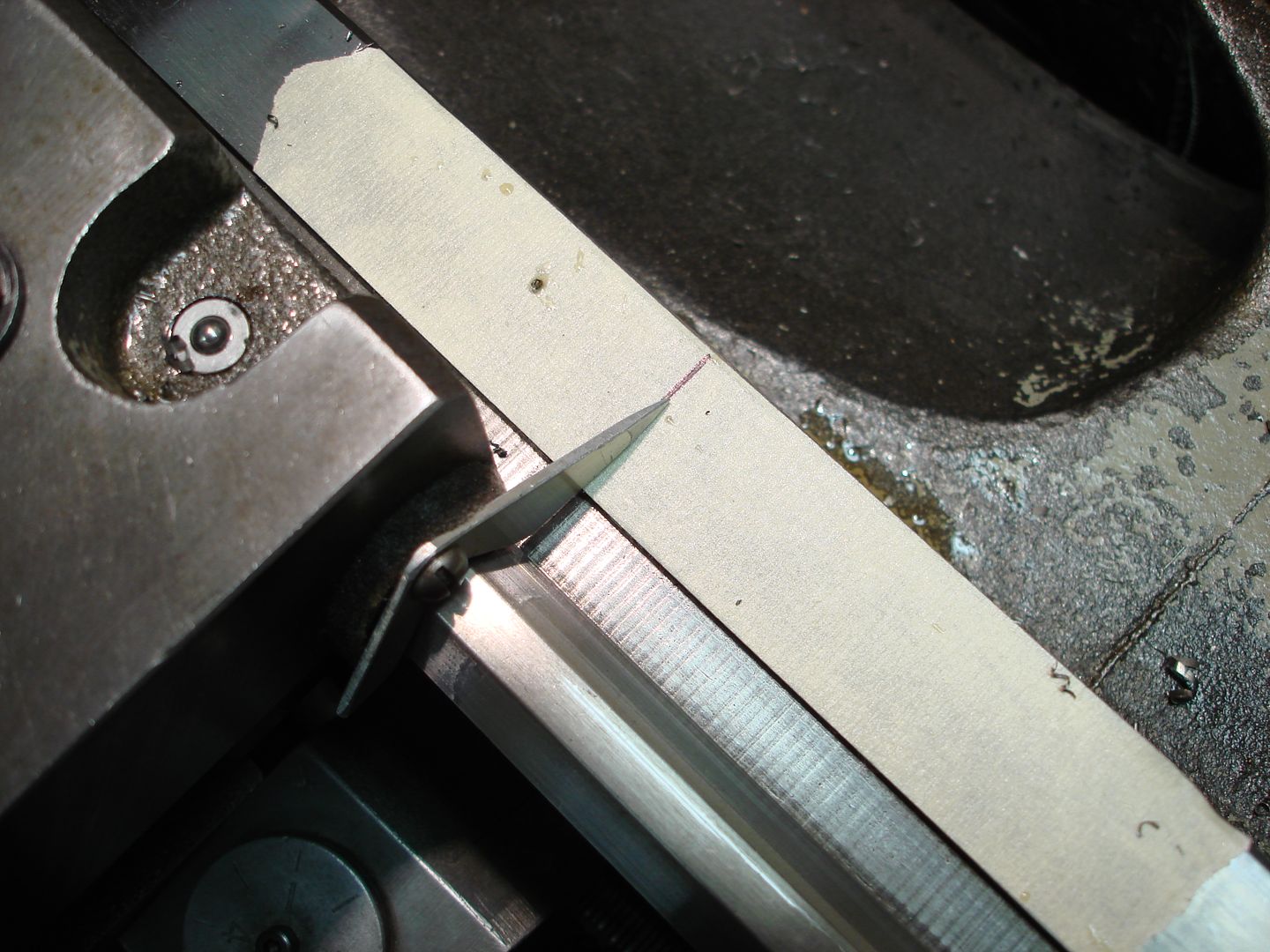

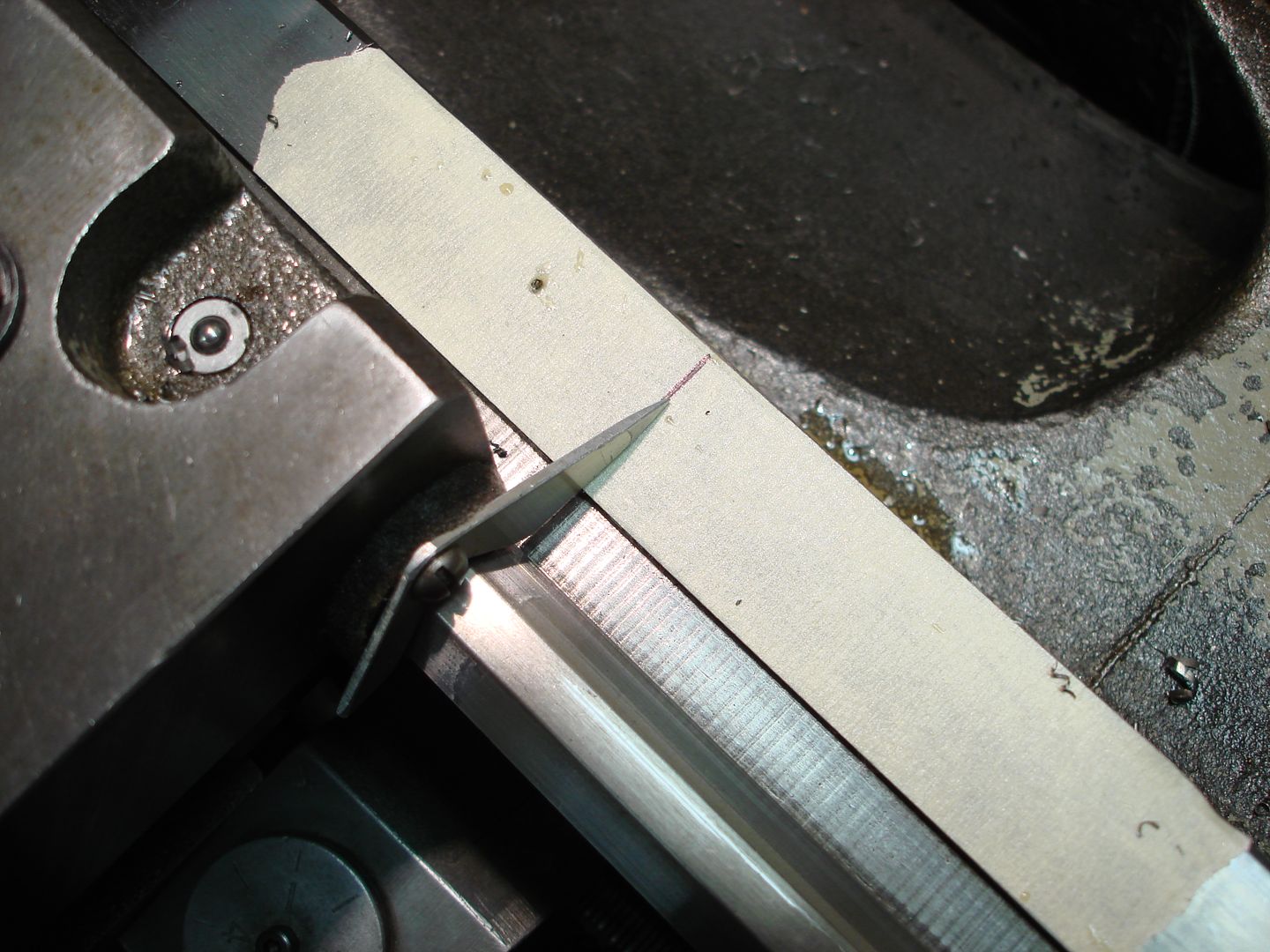

The easy way to do this, even if you can see what you are doing is a simple pointer attached to the lathe carriage. It this case mine mounts when needed to the way wiper.

Position the tool at the point in the bore where you need to dis-engage the half nuts and apply a piece of tape to the ways and mark the tape at the pointer.

Now the only thing you need to watch is the pointer lining up with the mark.

Takes the fun out of running into the shoulder !

The easy way to do this, even if you can see what you are doing is a simple pointer attached to the lathe carriage. It this case mine mounts when needed to the way wiper.

Position the tool at the point in the bore where you need to dis-engage the half nuts and apply a piece of tape to the ways and mark the tape at the pointer.

Now the only thing you need to watch is the pointer lining up with the mark.

Takes the fun out of running into the shoulder !