DickDastardly40

Well-Known Member

- Joined

- Oct 23, 2007

- Messages

- 309

- Reaction score

- 0

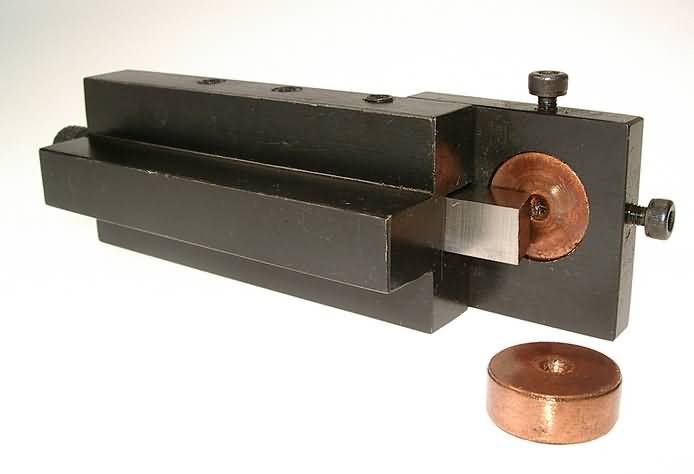

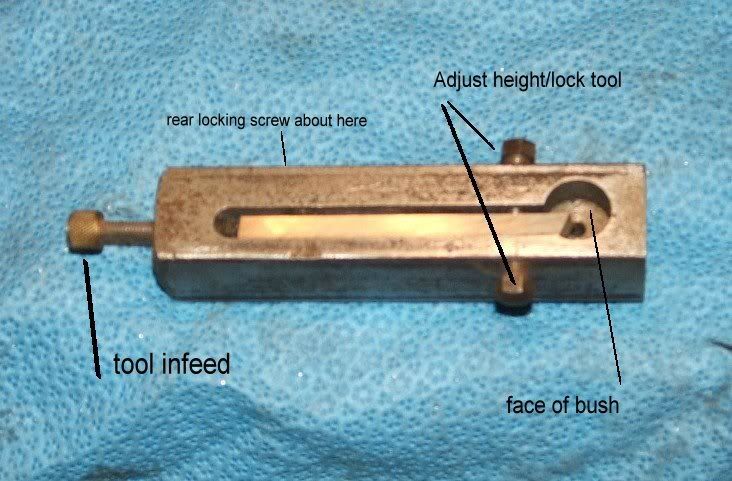

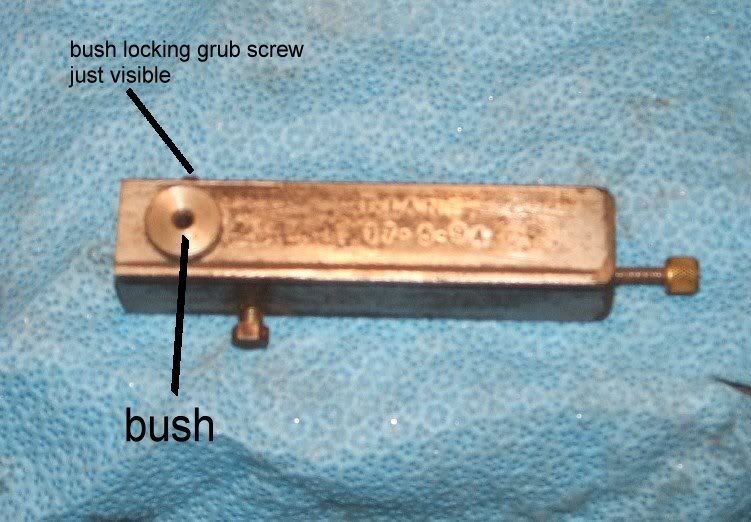

On another thread, Cedge asked Tel to show details of a tool for turning small diameters. As I am at a 'loose end' at work I thought I would submit a link to one I've seeen for sale by one of the 'usual supect' UK ME suppliers:

http://www.chronos.ltd.uk/cgi-local/sh000001.pl?REFPAGE=http%3a%2f%2fwww%2echronos%2eltd%2euk%2f&WD=sdtt&PN=Myford_Lathe_Compatible_Acessories%2ehtml%23aXC10_2e_2e_2e_2e#aXC10_2e_2e_2e_2e

No affiliation with seller but have bought several items from them over the years.

Hope this is of help to someone

Al

http://www.chronos.ltd.uk/cgi-local/sh000001.pl?REFPAGE=http%3a%2f%2fwww%2echronos%2eltd%2euk%2f&WD=sdtt&PN=Myford_Lathe_Compatible_Acessories%2ehtml%23aXC10_2e_2e_2e_2e#aXC10_2e_2e_2e_2e

No affiliation with seller but have bought several items from them over the years.

Hope this is of help to someone

Al