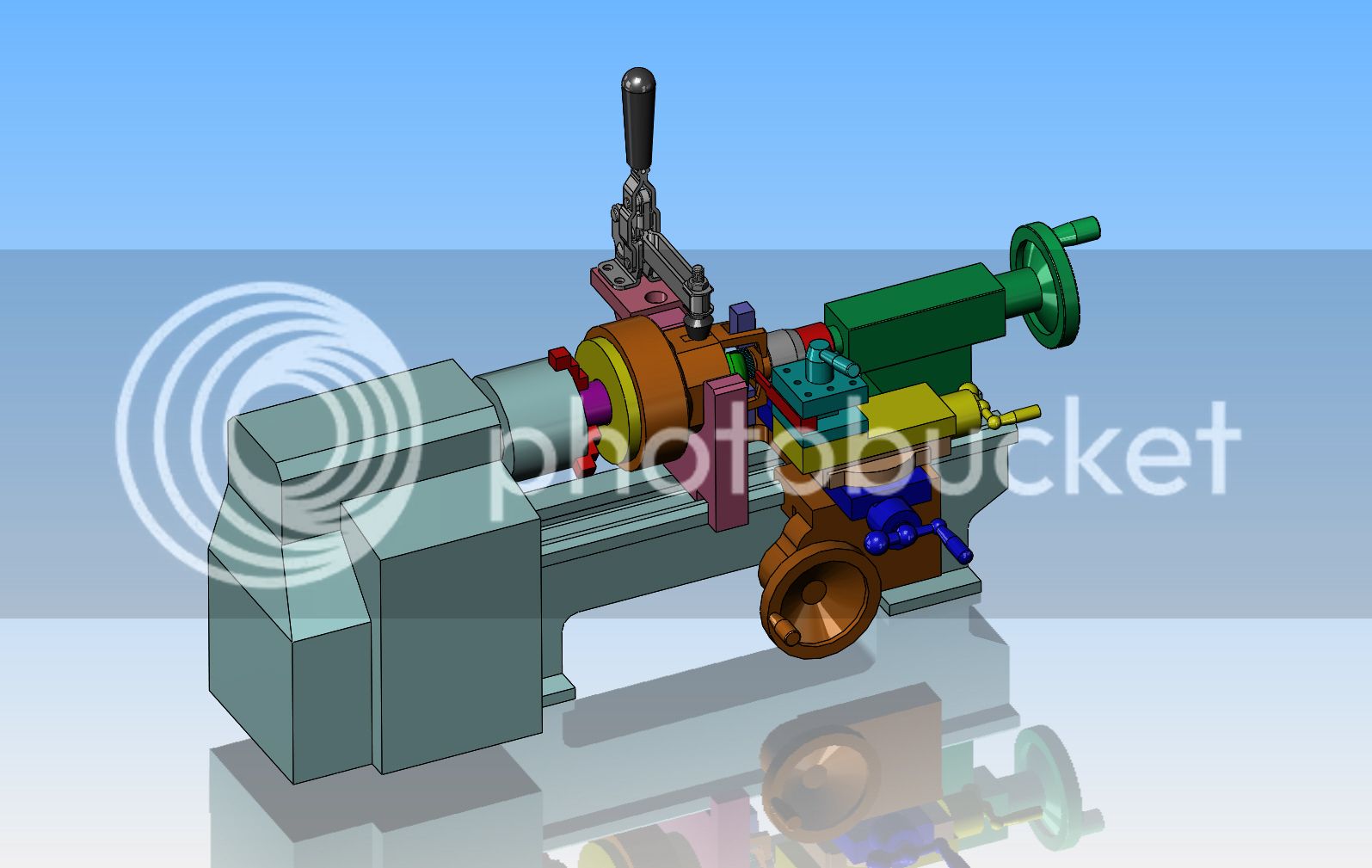

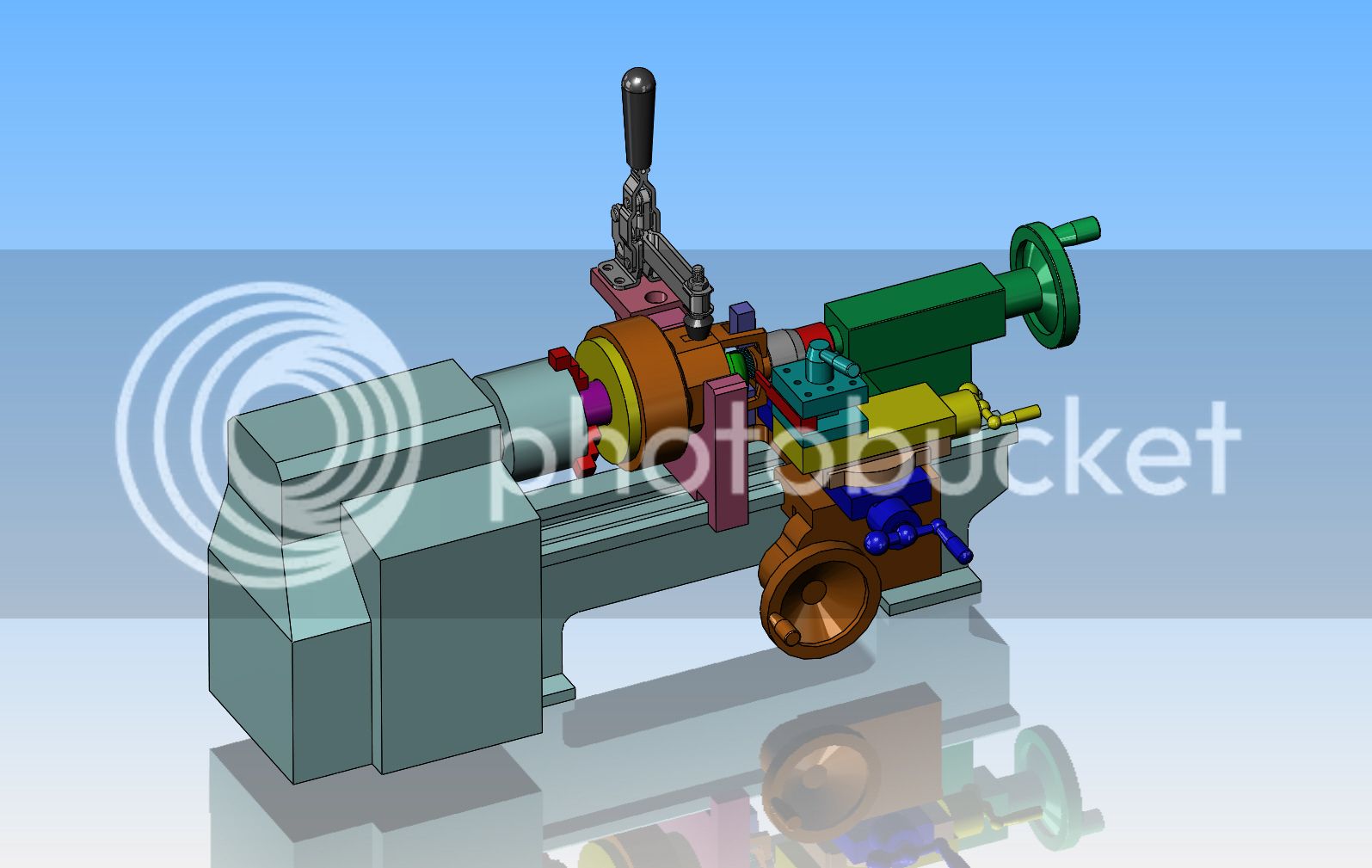

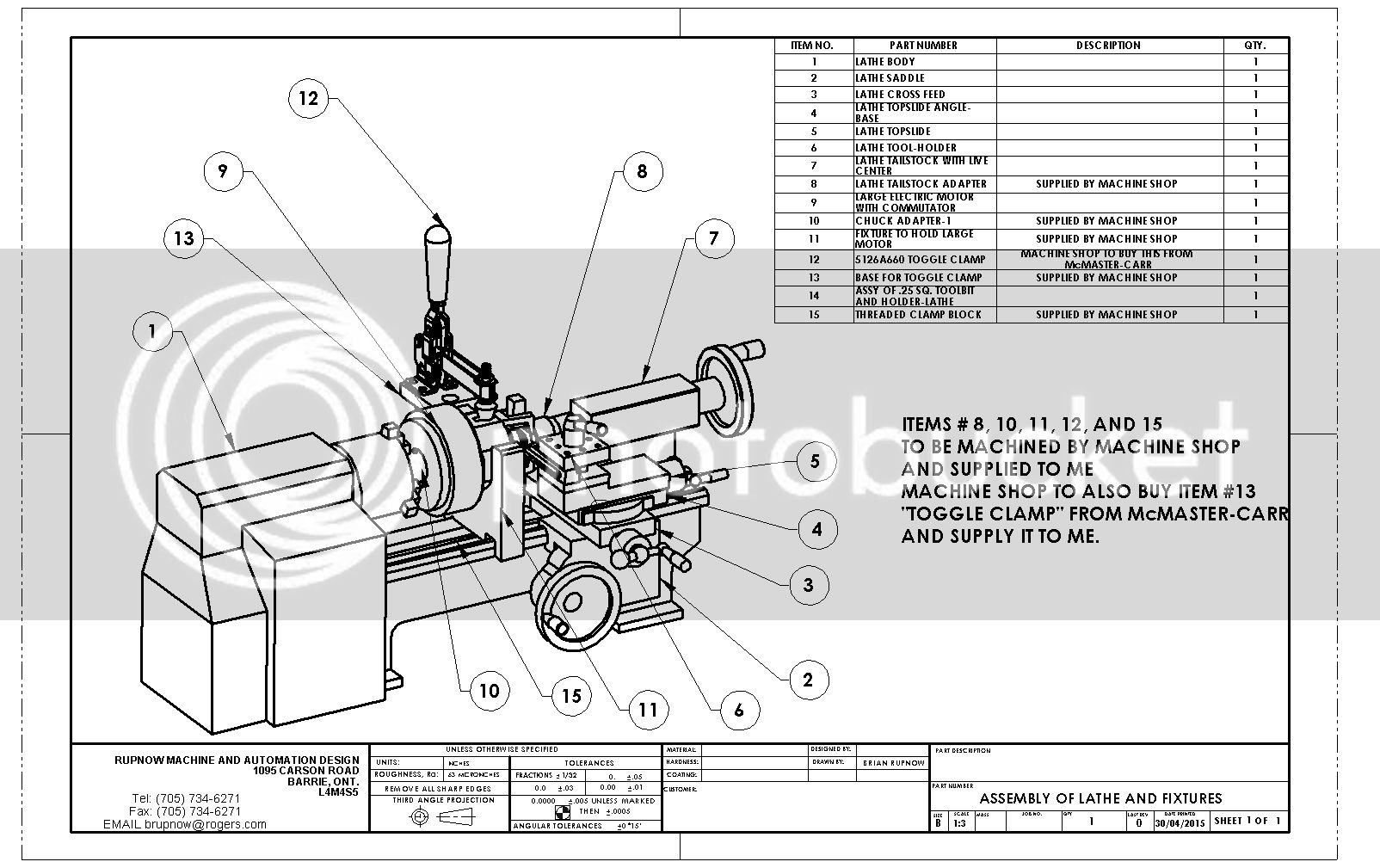

I built so many models over this past winter that I reached a point of total burn-out on machining. However, my daily engineering work goes on, and I have a customer who has to turn the commutators on a certain electric motor that he sells and services, which doesn't easily come apart. The decision was made to buy a mini lathe and make some special fixtures for it to hold the outer housing of the motor and use a drive dog mounted in the lathe chuck to spin the armature. So--I went to BusyBee tools on Saturday, purchased a mini lathe, and today I have modeled it, along with the fixtures required to mount and turn the motor. I love this kind of interesting thing when it comes along!!!---Brian