G'day folks

Its been a funny old week so far

Got my new mini Lathe and was happy to be getting the home workshop finally together,

started yesterday afternoon stripping the lathe down as it was a bit stiff with I thought the smelly oil the chinese folks use and hit a few "UH OH's"

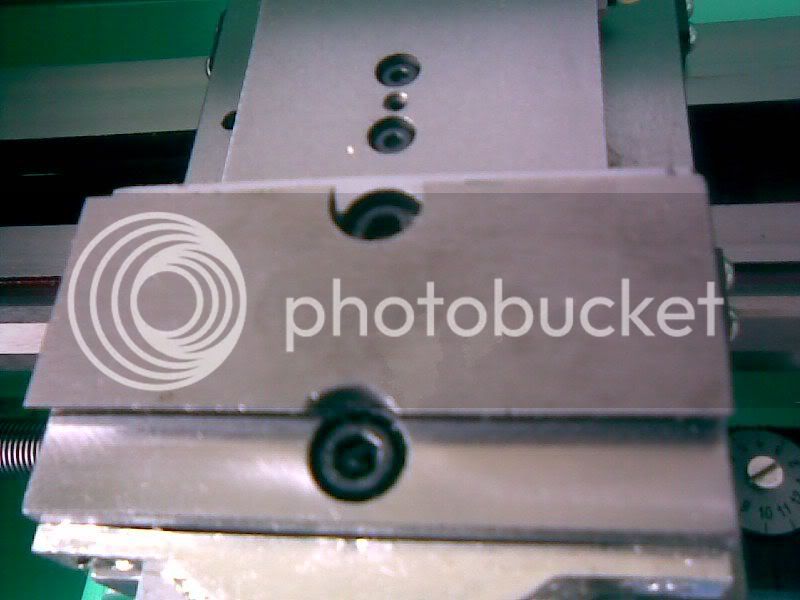

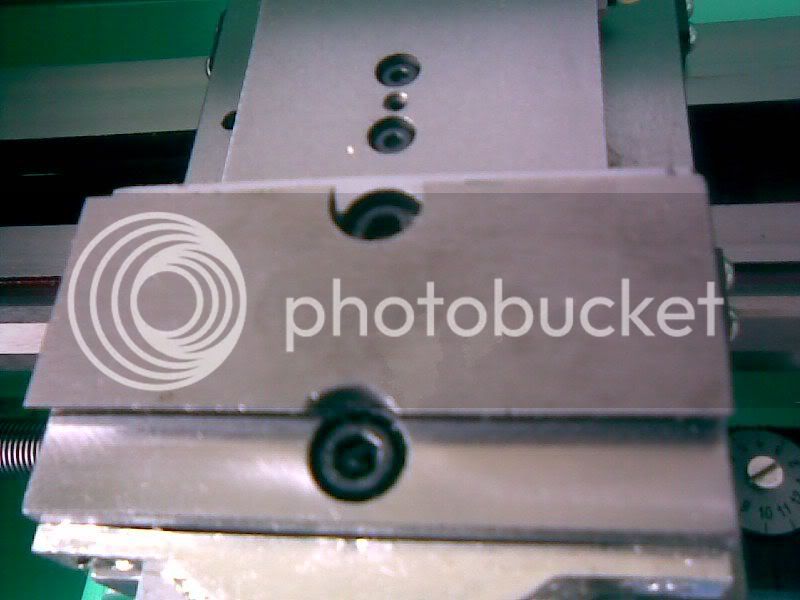

the finish on this lathe was ok in general but when i took the tool head and compound slide ( which where stiffer than alvin purple) off to clean i freaked

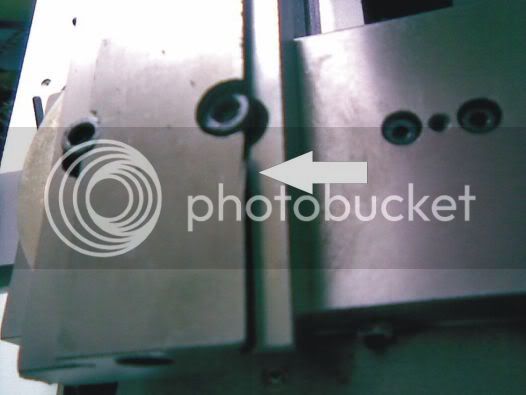

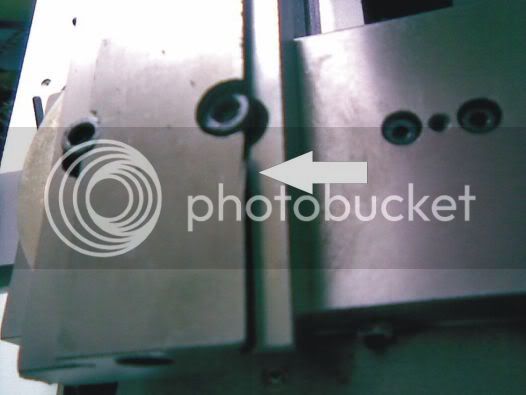

the gibs where shocking (POS i think is the US slang) i made a new one for it straight away and then sat down to figure what to do with the edges of the compound slide mounts, there was a 12 mm splinter in the middle

see second pic ( first pic is of other smaller nicks and dents)

i found that at 9pm last night so a very early trip this morning (5 am) to the big shop to grab the grinding unit from my big lathe and the mount post

i mounted the short post directly in the chuck and started the grinding process

( luckily i was at home today waiting for a delivery)

by 8am i had taken off an even 1mm of the slide and the big splinter was gone

then i took off a 0.5 mm off the top of the screw heads to ensure they did not hit the slide

after this i inserted the new gib ( 0.5 mm thicker than it should be but to allow the screws to still stay central)

mounted the compound slide and woohoo it was as smooth as a babies bum

i grabbed a bit of 1 1/4" stainless, as stainless shows inperfections and only using the compound slide started

a fine cut

despite the not so great tool that came with the lathe the cut was nice and smooth

new tools arrive next week and the rest i'll make as i go

I must admit i was sooooo ticked off when i saw how bad the finish was on this important peice on the machine but i am also sooooo happy i was able to bodgey it in my usual fashion

it was not a show stopper in my books and i realise for what i paid it is a cheap machine, however which way you cut it and not worth sending it back

I am mainly glad it wasn't on the cross slide where the oiler is located as retapping that and counter sinking it 1mm further down would have screwed me in a big way, and it would have gone back.

well my delivery arrived about 12:30 so i'll chuck the bird in its cage and go do some paying work

but do inspect any new purchase thoughly!! as soon as you get it eh!!

it pays

cheers all

jack

Its been a funny old week so far

Got my new mini Lathe and was happy to be getting the home workshop finally together,

started yesterday afternoon stripping the lathe down as it was a bit stiff with I thought the smelly oil the chinese folks use and hit a few "UH OH's"

the finish on this lathe was ok in general but when i took the tool head and compound slide ( which where stiffer than alvin purple) off to clean i freaked

the gibs where shocking (POS i think is the US slang) i made a new one for it straight away and then sat down to figure what to do with the edges of the compound slide mounts, there was a 12 mm splinter in the middle

see second pic ( first pic is of other smaller nicks and dents)

i found that at 9pm last night so a very early trip this morning (5 am) to the big shop to grab the grinding unit from my big lathe and the mount post

i mounted the short post directly in the chuck and started the grinding process

( luckily i was at home today waiting for a delivery)

by 8am i had taken off an even 1mm of the slide and the big splinter was gone

then i took off a 0.5 mm off the top of the screw heads to ensure they did not hit the slide

after this i inserted the new gib ( 0.5 mm thicker than it should be but to allow the screws to still stay central)

mounted the compound slide and woohoo it was as smooth as a babies bum

i grabbed a bit of 1 1/4" stainless, as stainless shows inperfections and only using the compound slide started

a fine cut

despite the not so great tool that came with the lathe the cut was nice and smooth

new tools arrive next week and the rest i'll make as i go

I must admit i was sooooo ticked off when i saw how bad the finish was on this important peice on the machine but i am also sooooo happy i was able to bodgey it in my usual fashion

it was not a show stopper in my books and i realise for what i paid it is a cheap machine, however which way you cut it and not worth sending it back

I am mainly glad it wasn't on the cross slide where the oiler is located as retapping that and counter sinking it 1mm further down would have screwed me in a big way, and it would have gone back.

well my delivery arrived about 12:30 so i'll chuck the bird in its cage and go do some paying work

but do inspect any new purchase thoughly!! as soon as you get it eh!!

it pays

cheers all

jack