Oldmechthings

Well-Known Member

- Joined

- Jan 10, 2008

- Messages

- 153

- Reaction score

- 12

Yesterday on a post about an air operated engine, cfellows asked where I was.

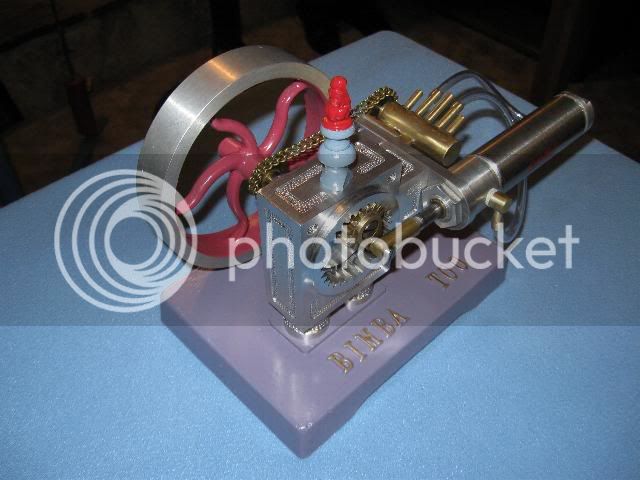

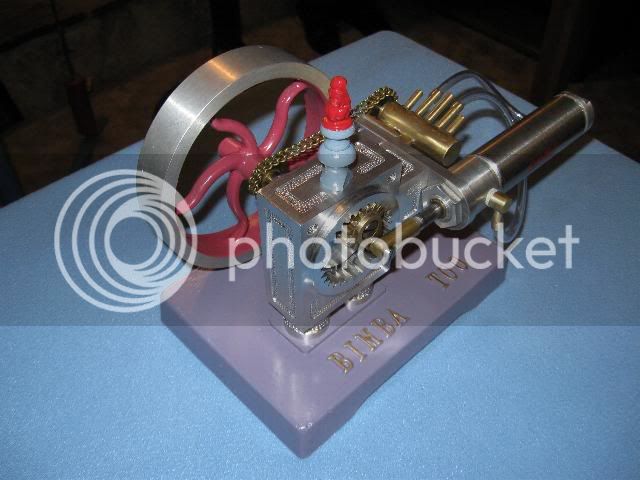

Just to let everyone know, I'm still around producing things as fast as I can, I'll post a picture for you to look at. It is a simple little geared engine, that is a little different than normal. It has a big hard to pronounce and understand name, but I do not like to use those kind of words. It uses a Bimba brand pneumatic cylinder, and that is where it got its name I gave it, and a chain driven rotary valve, just to make it different.

It has an odd number, crooked spoke flywheel, that I have taken a liking too. Remember about a year ago Powerkeg, in one of his CNC classes, programmed and routed out a pattern for it. I was given a casting and so I now use that as a pattern to make my own castings and have used it on a couple models. I call it a "Pilley" wheel after the designer.

If you would like to see a short video of the engine running, it is posted on the Blog: http://birkpetersens.blogspot.com/

Birk ;D

Just to let everyone know, I'm still around producing things as fast as I can, I'll post a picture for you to look at. It is a simple little geared engine, that is a little different than normal. It has a big hard to pronounce and understand name, but I do not like to use those kind of words. It uses a Bimba brand pneumatic cylinder, and that is where it got its name I gave it, and a chain driven rotary valve, just to make it different.

It has an odd number, crooked spoke flywheel, that I have taken a liking too. Remember about a year ago Powerkeg, in one of his CNC classes, programmed and routed out a pattern for it. I was given a casting and so I now use that as a pattern to make my own castings and have used it on a couple models. I call it a "Pilley" wheel after the designer.

If you would like to see a short video of the engine running, it is posted on the Blog: http://birkpetersens.blogspot.com/

Birk ;D