I response to Chuck's space saving post, I thought I'd post one of my own (and not hijack his thread).

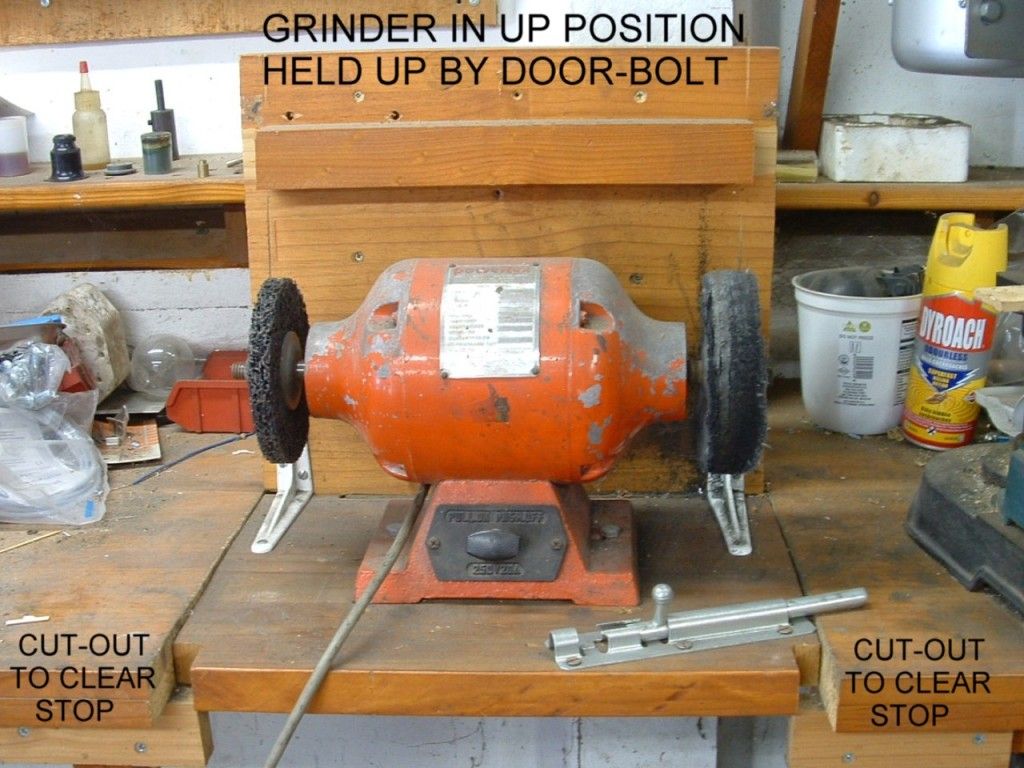

This is my "polishing" bench grinder (so don't give me lip over the absent gaurds and rests) which otherwise occupies an inordinate amount of bench space for the use it gets.

So I sawed a section of bench out and mounted it on this trapdoor arrangement.

Works fine.

In the up position it is held by the door bolt, in the down position it rests on protruding stub sections of the support stile - there are cut-outs in the bottom part to clear the stubs - hence the bolt to keep it up.

Ken

This is my "polishing" bench grinder (so don't give me lip over the absent gaurds and rests) which otherwise occupies an inordinate amount of bench space for the use it gets.

So I sawed a section of bench out and mounted it on this trapdoor arrangement.

Works fine.

In the up position it is held by the door bolt, in the down position it rests on protruding stub sections of the support stile - there are cut-outs in the bottom part to clear the stubs - hence the bolt to keep it up.

Ken