Train_Fan

Active Member

- Joined

- Apr 16, 2013

- Messages

- 25

- Reaction score

- 8

So I am making myself a wooden wood lathe as seen here: http://www.homemodelenginemachinist.com/f31/making-myself-handy-tool-lathe-21664/

And I have a question regarding my material choice for the driveshaft that will run the chuck.

Reposted from the thread:

Thanks for any input!

And I have a question regarding my material choice for the driveshaft that will run the chuck.

Reposted from the thread:

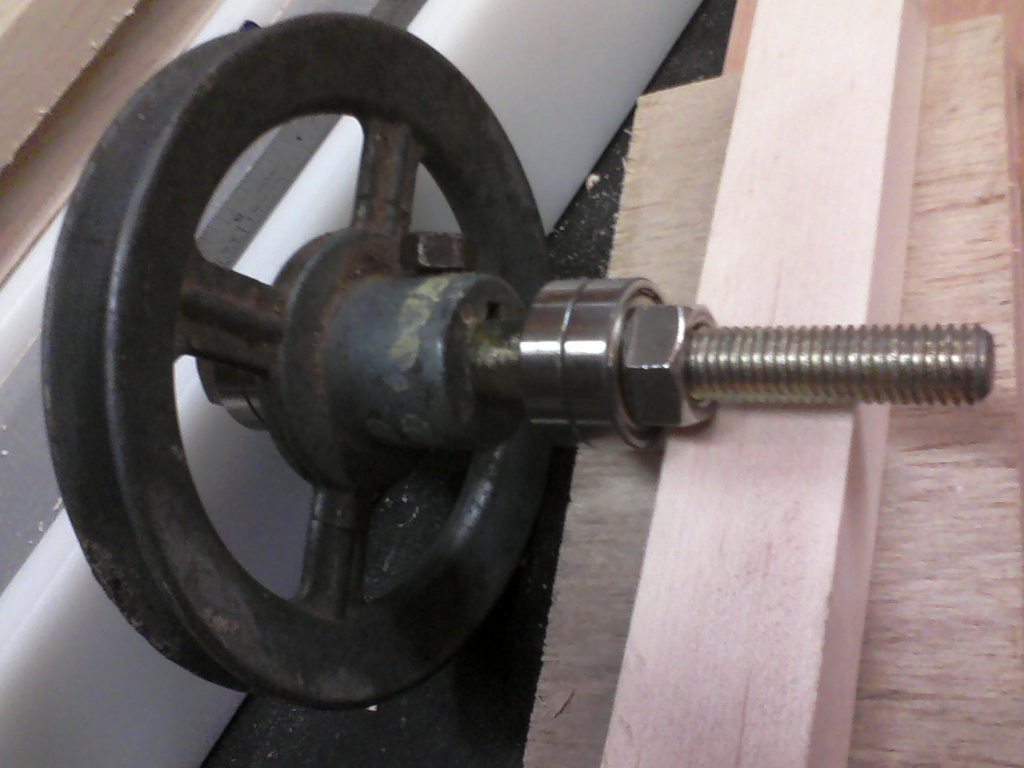

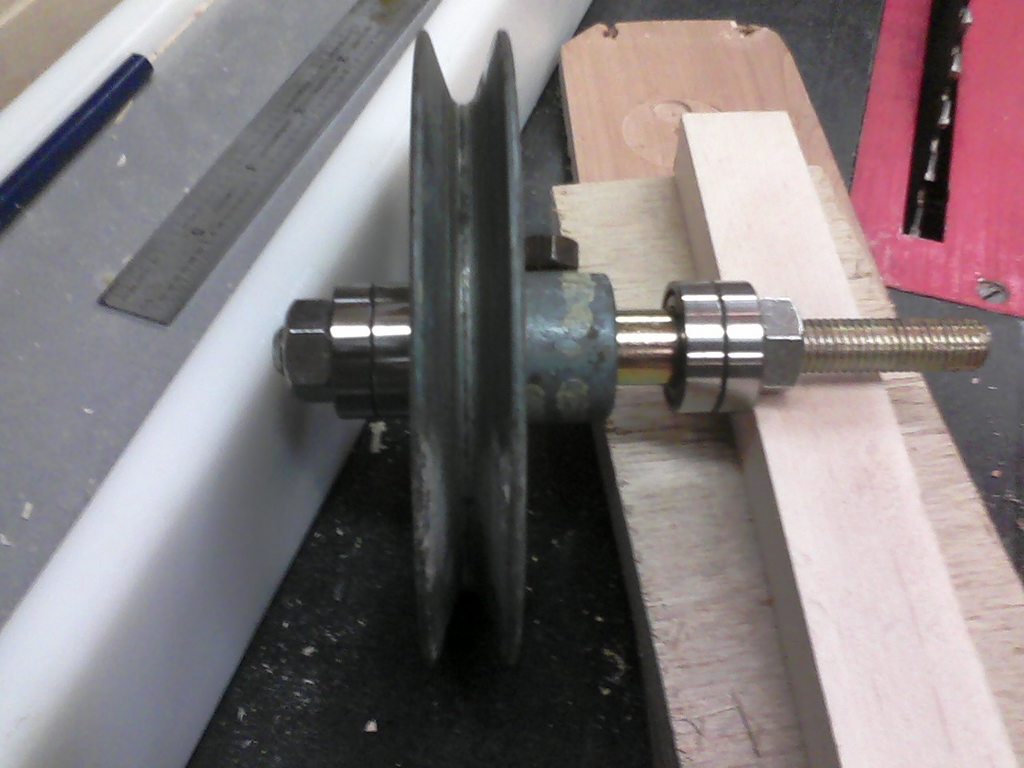

After assembling what I have shown for a shaft, my father told me that the 1/2" All-Thread I was using was not a suitable item as a shaft, and after some thought I'd tend to agree given that it is a material designed for tension, not torsion. As you all deal with this material more than I do and have better understanding of the forces involved, what is your input? Is it fine as-is, or should I order in real shafting, along with bearings and blocks?

Thanks for any input!