Hi all

I was reading a book on steam engines (most of their examples were pretty big, around 25in piston diam...)

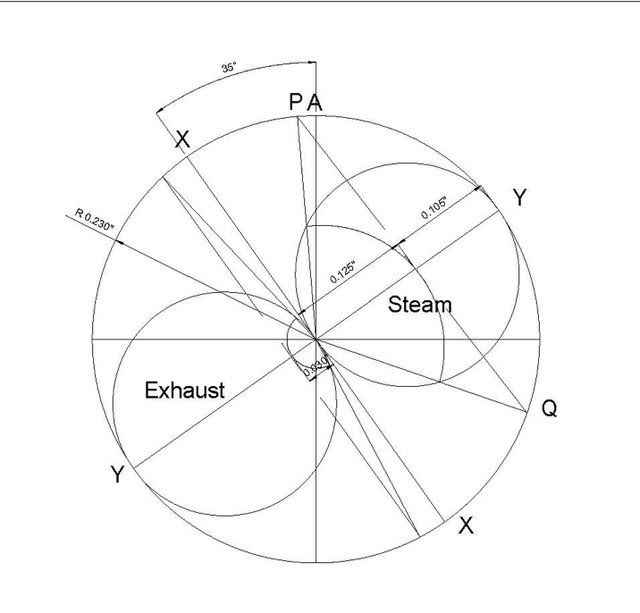

and they were explaining how does steam/exhaust lead/lap work, also some design of double ported slide valves,

the relation between valve and piston speed with different linkages, and other "fancy" stuff.

I would like to know if any of you, as modeler, or full size (reasonable size, as for small boats) engine maker, ever think

about these things when you design or build an engine, or, as me (yet), don't bother much an let steam in and out at TDC and BDC

and smile looking at the engine running cause it will still runs pretty well anyway!

I don't know if they use these kind of techniques only for huge engine since it does influence the power and efficiency,

or even for small scale engine these things are "critical".

Thanks, Deckel

I was reading a book on steam engines (most of their examples were pretty big, around 25in piston diam...)

and they were explaining how does steam/exhaust lead/lap work, also some design of double ported slide valves,

the relation between valve and piston speed with different linkages, and other "fancy" stuff.

I would like to know if any of you, as modeler, or full size (reasonable size, as for small boats) engine maker, ever think

about these things when you design or build an engine, or, as me (yet), don't bother much an let steam in and out at TDC and BDC

and smile looking at the engine running cause it will still runs pretty well anyway!

I don't know if they use these kind of techniques only for huge engine since it does influence the power and efficiency,

or even for small scale engine these things are "critical".

Thanks, Deckel