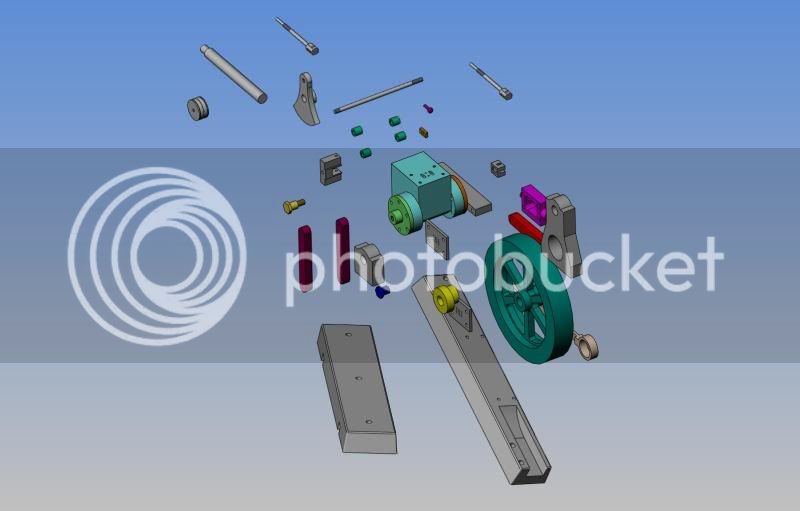

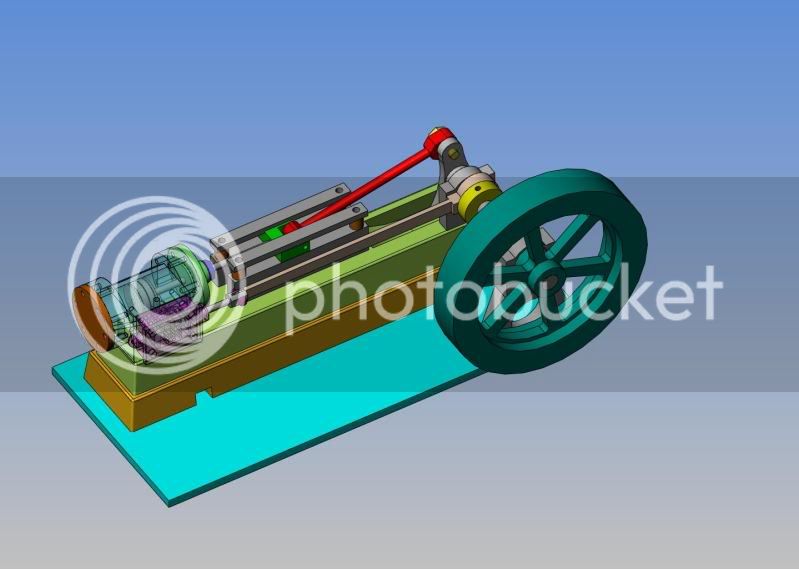

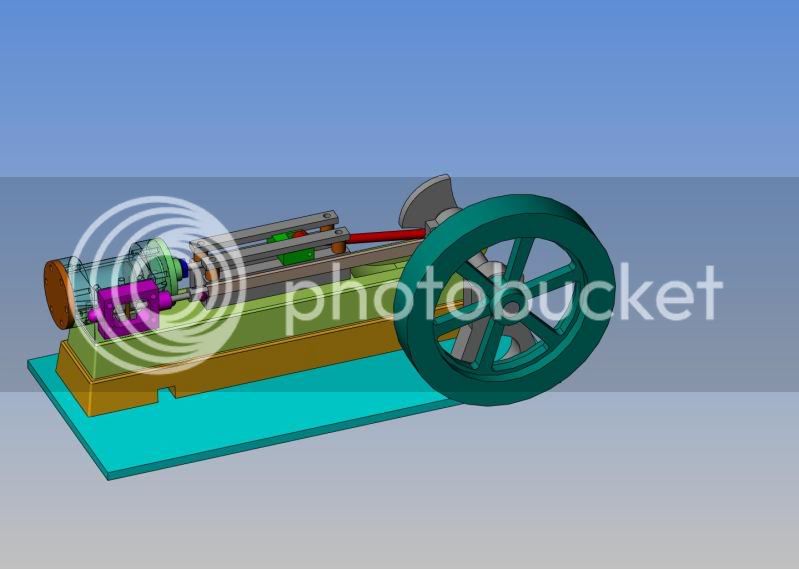

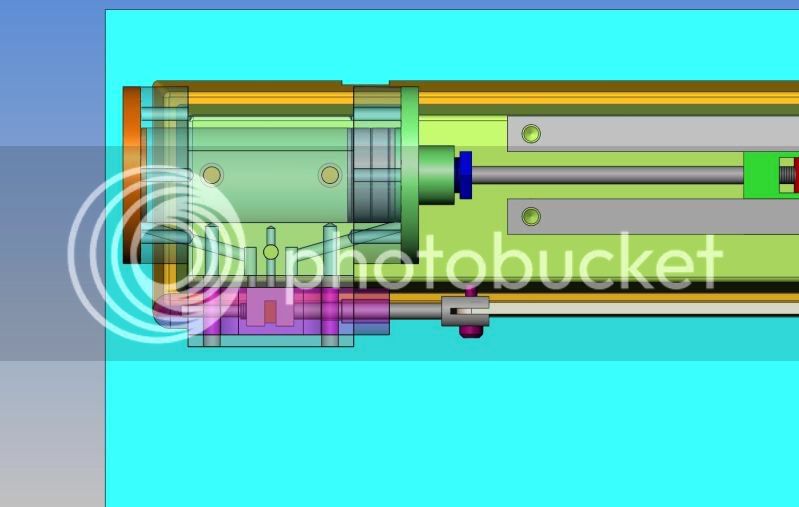

Although I have been playing about with model steam/air engines for 2 years now, I still do not have a clearly defined understanding of valve design for a double acting air engine. If we leave "lag" and "lead" out of the equation, I want to know the following information. For a "given" stroke and piston length, how does one go about calculating A--The "throw" on the valve eccentric, B--the length of the "big ends" on the spool valve, the distance between the inlet and outlet ports, C--the distance between the "big ends" on the spool valve. I am sure that this information can all be reduced to a set of formulae that will cover any double acting air engine, but I haven't been able to find it, and I don't seem to be able to figure it out by myself. This all shows up in the attached .gif which was so kindly provided by Maryak. If anyone can help withthis, it would be an immense help to myself and to all other model engineers.---Brian