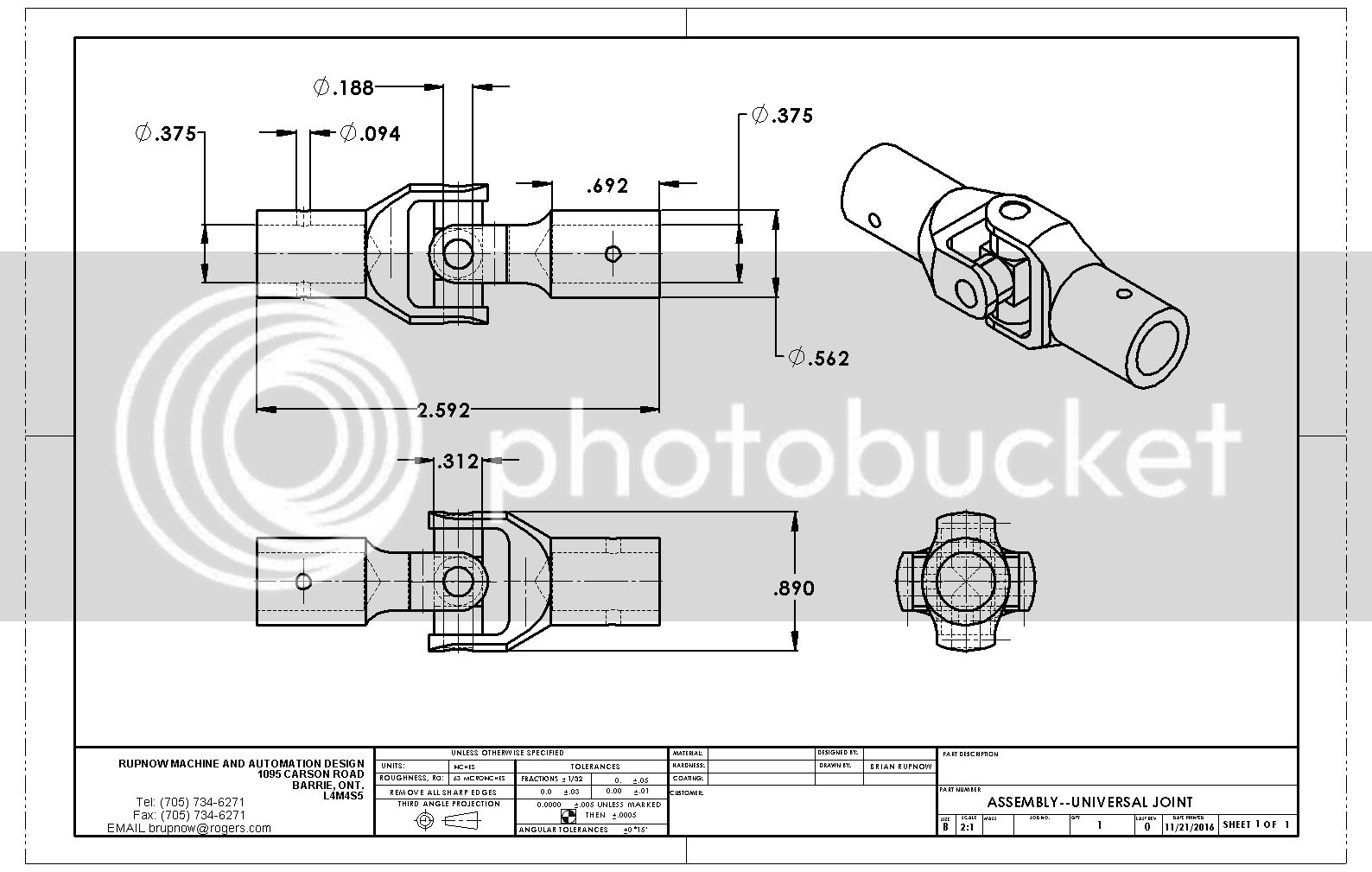

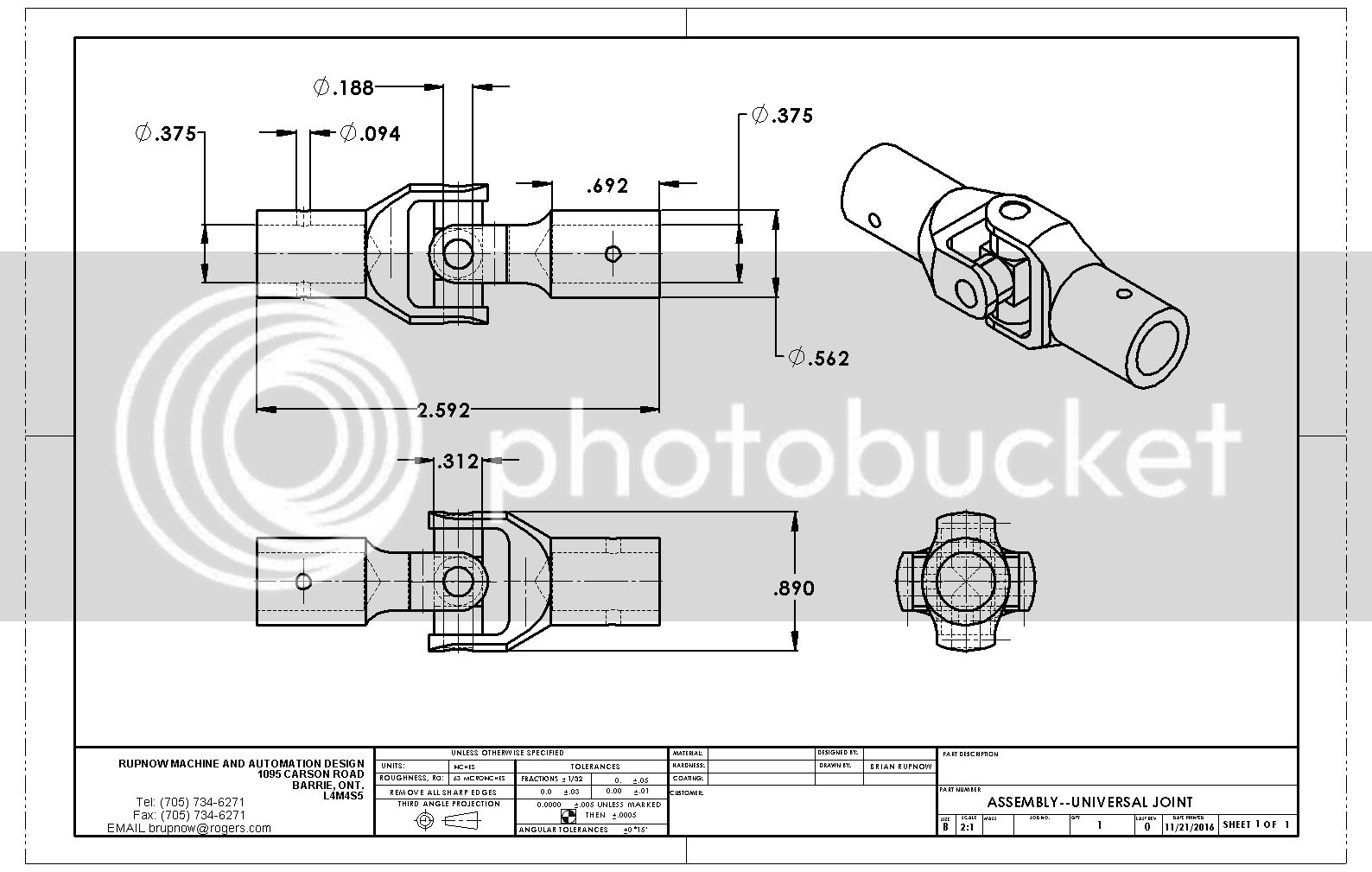

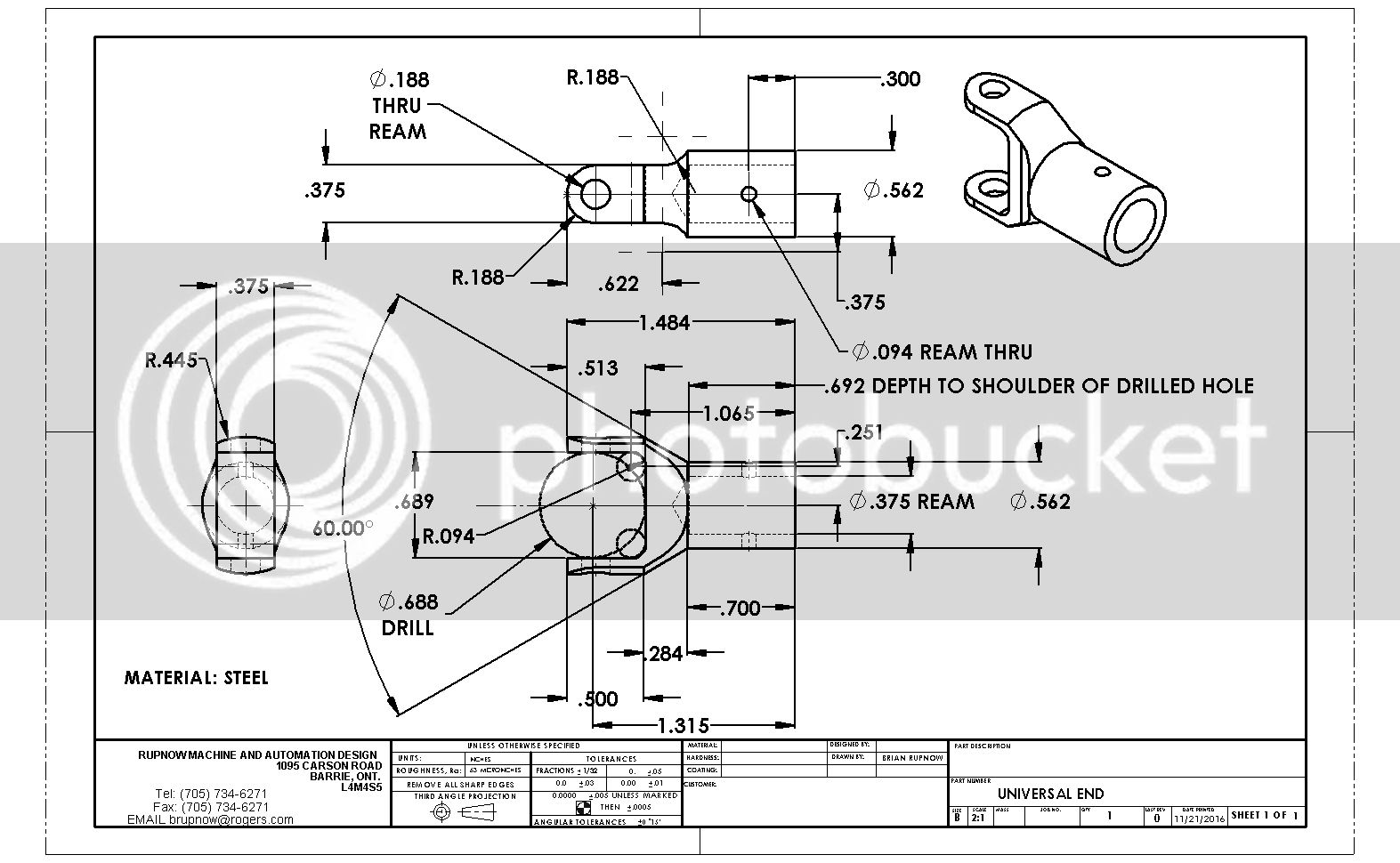

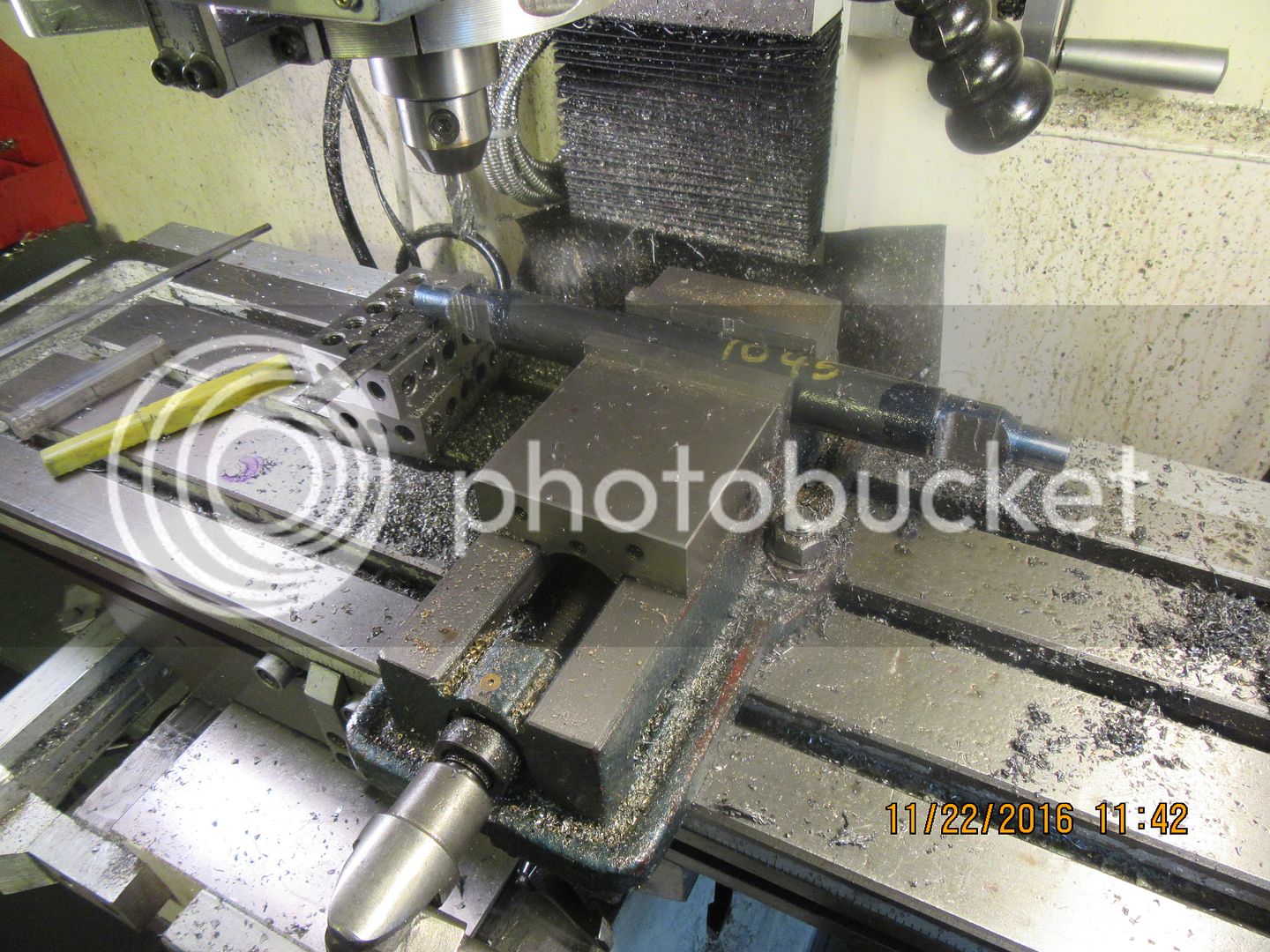

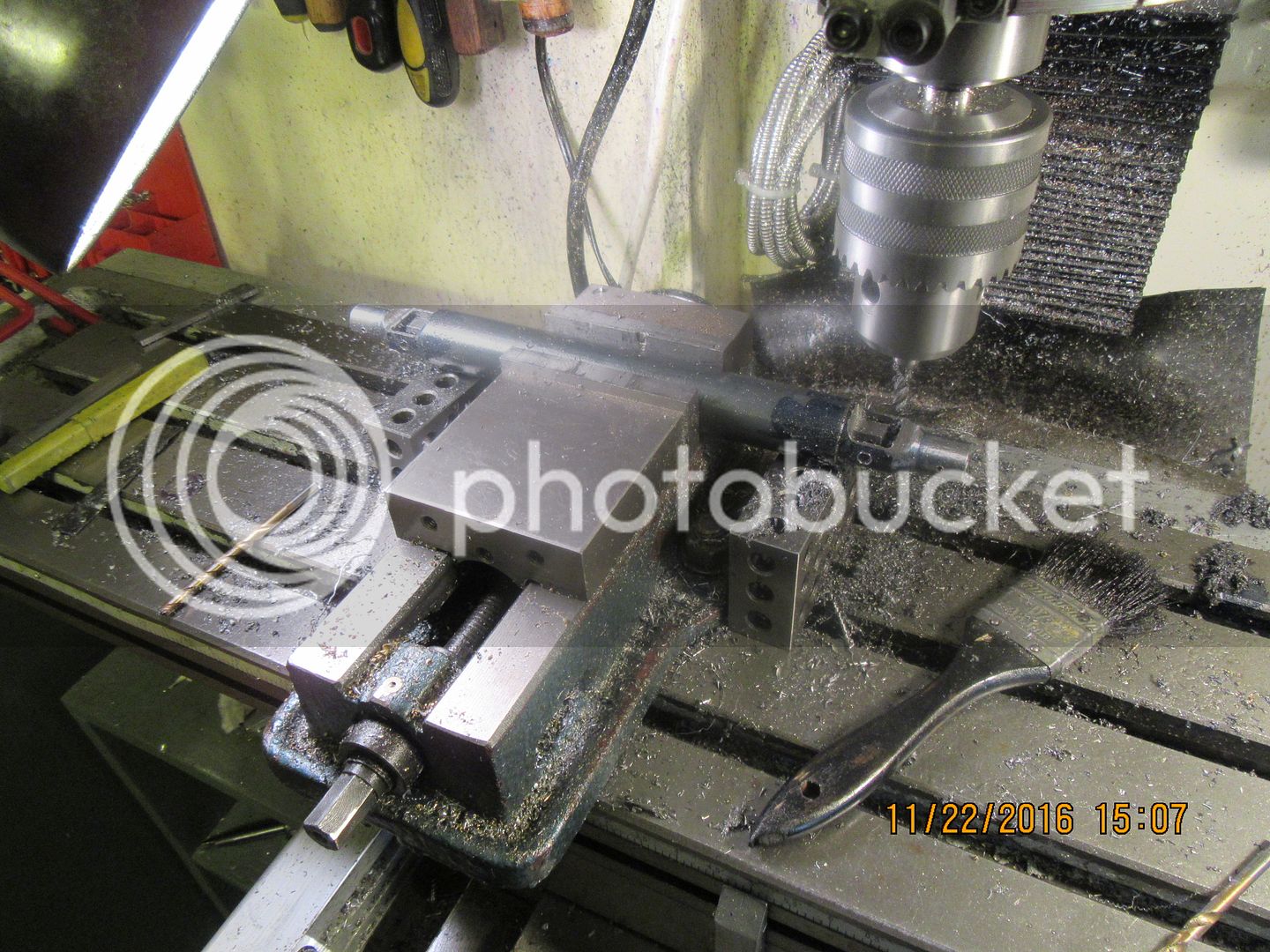

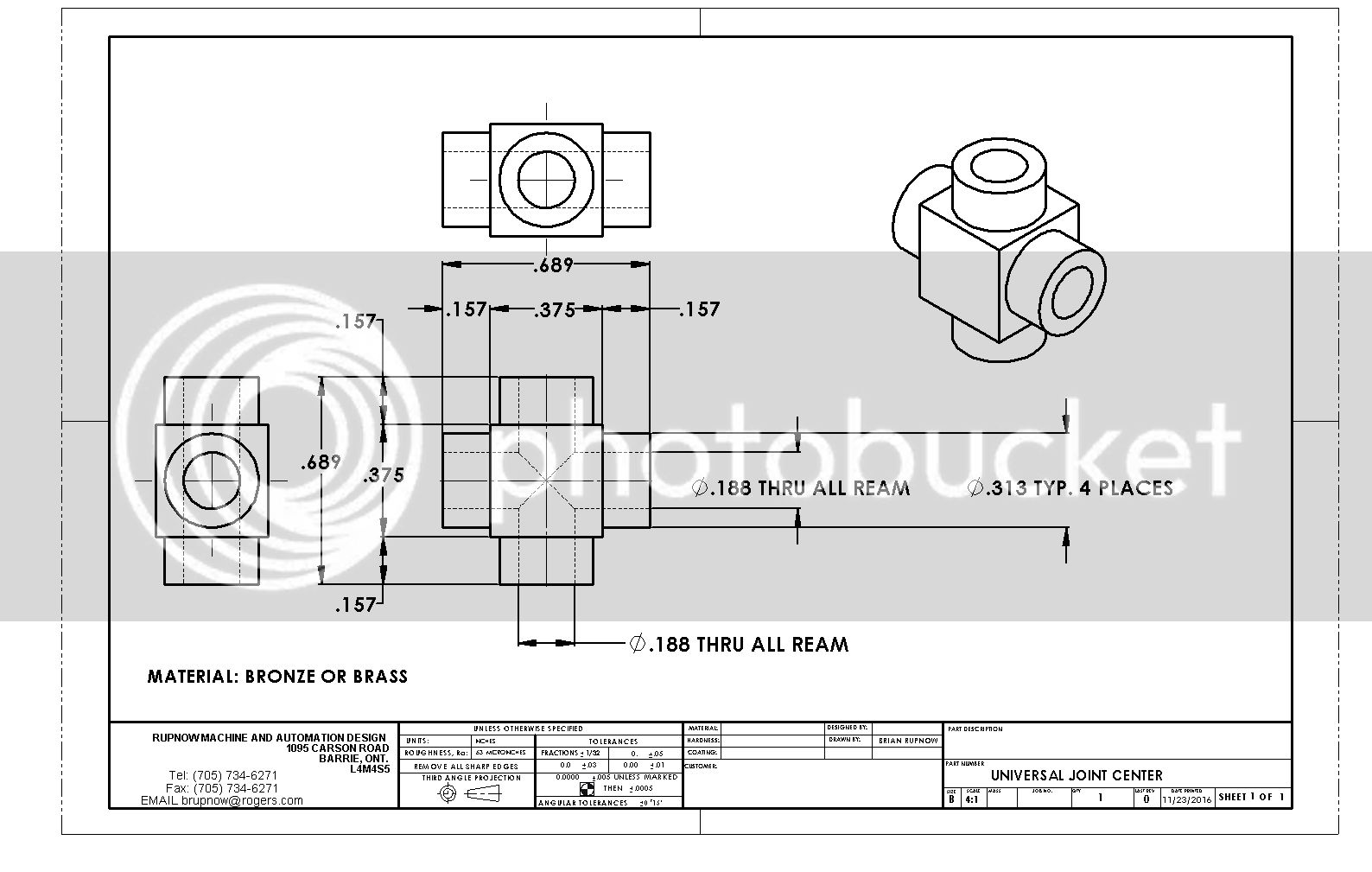

This is something that's been coming for a long time. Every model machinist, wants deep in his heart of hearts to make a universal joint. You have to reach a certain point of confidence in your ability to machine things and be bored enough to consider a project like this. The worst thing is that one universal by itself isn't much good. To really show them working properly, you need two of the darned things working together. I'm kind of dancing from one customer to another on small jobs with free time and wait periods in between spots of real work, so I think I'll try and make a couple of these.