- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

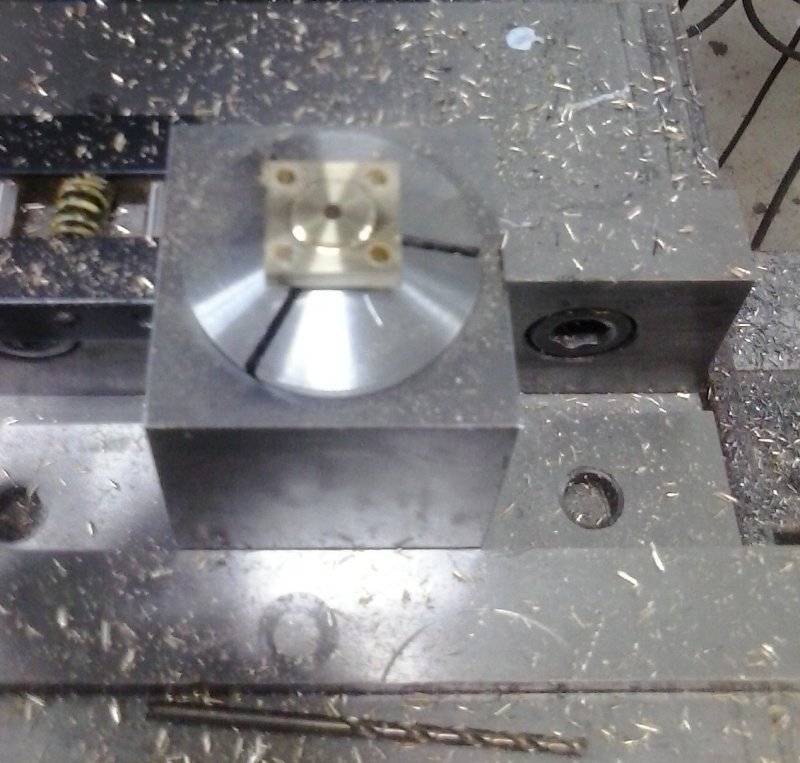

Having gotten the Muncaster engine to the initial run state I have decided to revive my example of the Comber engine, Elmer's #46. The parts have been sitting is a storage drawer in my shop since 2008. One reason I didn't continue is that I didn't get parts from everyone on the team, and as well got interested in other projects. I've been thinking of getting it running for CF, so I have about 2 weeks to make the missing parts and get a runner. Personal challenge!

Taking inventory it appears that the parts I need to make are:

Two heads

Two rollers

Two pins

Air inlet barb

The hard parts are in hand, although attention will need to be paid to fitting, esp. with the bearings.

Taking inventory it appears that the parts I need to make are:

Two heads

Two rollers

Two pins

Air inlet barb

The hard parts are in hand, although attention will need to be paid to fitting, esp. with the bearings.